IMPORTANT SAFETY INSTRUCTIONS

When installing and operating this Product and other associated equipment, basic safety precautions should always be

followed.

1. This Control must be installed by a qualified person, according to National and Local Electrical Codes.

2. Install this Control not less than 5 feet (3 meters in Canada) from inside edge of pool and 1 foot (30cm) above ground.USE

COPPER CONDUCTORS ONLY rated minimum 75˚ C.

3. Do not exceed the maximum ratings of individual components, wiring devices, and current carrying capacity of conductors.

4. For Control grounding, bonding, installing and the wiring of underwater lights, refer to Article 680 of the National Electrical Code

or Article 68 of the Canadian Electrical Code.

5. The Control should not operate any equipment which would cause bodily injury or property damage should it be activated

unexpectedly.

2

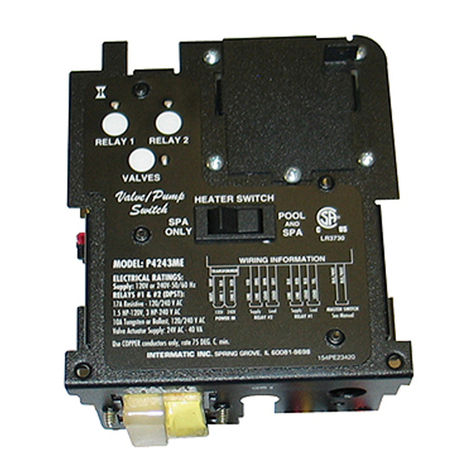

INSTALLATION - MODEL PF1103

1. Select the proper outdoor location for the

Freeze Protection Control and prepare the

necessary conduit run(s) required by the

installation layout.

2. Hang enclosure on a flat vertical surface or

other support, preferably next to the Switching

Device, using hardware

suitable for the purpose.

3. Properly terminate

conduits at both ends

and pull-in the

conductors as specified by the installation layout.

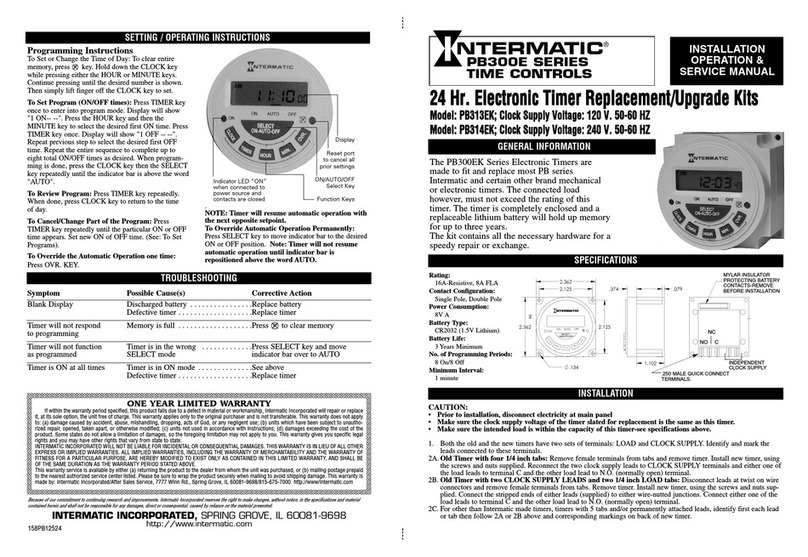

4. Select the appropriate wiring diagram (120 V.

or 240 V. installation) on page 3 or 4 of this

manual and make LINE and LOAD (Pump)

connections as shown. Wiring the Freeze

Control, first identify each lead by its color

then make wire connections by using wire

nuts. wiring the Time Switch, if it is Intermatic,

follow the diagram. Make connections to

terminal block as shown, see insert above for

Time Switch made prior to 1984 by Intermatic

or made by another manufacturer or it is an air

switch, first identify the LINE and LOAD

terminals of the control and wire the two

devices in Parallel.

Make sure the installation is properly grounded.

5. If the Freeze Protection Control is installed in

location, where it is exposed to direct sun

most of the day, extend 8 inches of the

copper capillary tube of the thermostat into an

open ended (plastic or metal) conduit, about

10 inches long, installed at bottom of the

enclosure. Handle capillary tube with care!

6. TEST INSTALLATION:

a. Turn the thermostat dial to its lowest setting

and place crushed ice (in plastic bag) inside

capillary coil of Thermostat.

b. Turn ON power to Control Panel, wait one

minute then slowly turn thermostat dial

counterclockwise until Filter Pump starts.

c. Turn power OFF to Control, remove ice,

check wiring, tighten terminal screws if

necessary, reinstall front plate.

d. Turn power ON to Control and set Time

Switch and the Thermostat, see

OPERATION instructions below.

Install mechanism in any Intermatic Pool

Panel with only one Time Switch by snapping

it into the unused mounting bracket, furnished

with the Panel and follow steps 4 to 6 above.

PRESSURE PLATE

TERMINAL SCREW

MAKE SURE INSULATION

CLEARS PRESSURE PLATE

CONDUCTOR

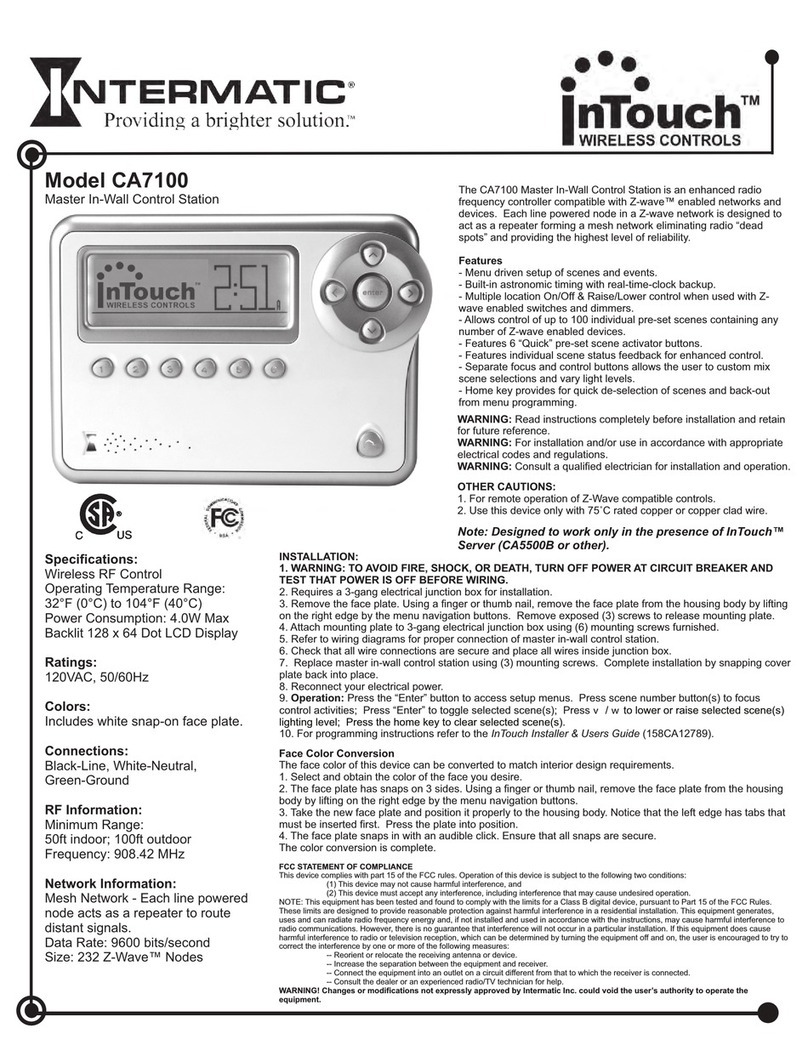

TO SET THERMOSTAT, turn dial, pointing to desired temperature between 32˚F and 45˚F, marked on

the plate. Remember, many variables, such as the location of the Freeze Protection Control, the location

of equipment and the pool or spa, the location and insulation of the plumbing, etc., must be considered

before selecting the “turn ON” temperature of the Filter Pump. Your local pool service professional is the

best source of information. The Thermostat is factory set to turn OFF the Filter Pump when the ambient

temperature rises 5˚F above its set point.

TO SET TIME SWITCH, follow instructions inside Time Switch enclosure cover.

OPERATION

INSTALLATION - MODEL PF1103M