3

ReadySet™ Electronic Valve Actuator

Programming

To reprogram the actuator stop points, follow these steps:

Note: Green on the indicator light indicates the first program point regardless of the direction moved to reach the program

point. When the stop points are programmed, the actuator will always move between the 0° and 270° positions. The

actuator will not accept or move automatically through a programming point between 270° and 360° (some leeway is

allowed for seal optimization at 0° and 270°).

1. Flip the toggle switch to the position that causes no motion. If the toggle switch is flipped to a position that initiates

motion, reverse the toggle switch and wait until the actuator stops motion.

2. With the actuator stopped, flip the toggle switch into the center (OFF) position and wait approximately five (5) seconds.

The actuator will sound a beep and flash a green indicator light for 10 seconds, to indicate that it is in PROGRAMMING

MODE. Initiate the programming during these first 10 seconds.

Note: If you miss the 10-second time to initiate movement toward the first stop point, the actuator will go into OFF

MODE. The current programmed stopped points are not lost. See “Manual Rotation” on page 4 for steps to

exit OFF MODE and re-initiate programming.

3. Flip the toggle switch to the position that will rotate the actuator toward the first desired program point.

Note: If the toggle switch position rotates in the opposite direction from the desired point, reverse the toggle switch

position and proceed with the instructions.

4. Once the small slot reaches the desired position, flip the toggle switch to the center position.

The actuator will beep and the indicator light will change from flashing green to flashing blue.

5. To set the second stop point, flip the toggle switch to the opposite position of the last move.

Note: If the movement toward the second stop point is not initiated, the actuator will flash red and beep repeatedly.

Moving the toggle switch to initiate rotation will restart the flashing green, indicating that the process is starting over.

6. Once the slot reaches the desired position, flip the toggle switch back to the center position.

The actuator will continue flashing blue for a few seconds, then play a long beep and 2 short beeps, then change the

indicator light to solid red. This indicates the program is accepted.

7. Testing the stop points and operation at this time is recommended.

a. Flip the toggle switch in the direction of the last movement.

The actuator should already be at the stop point and should not move. This indicates that the actuator is ready for

AUTO operation between the two programmed points.

b. Flip the toggle switch in the opposite position.

The actuator will start to move toward the first programmed test point and stop automatically. This indicates that the

actuator is ready for AUTO operation.

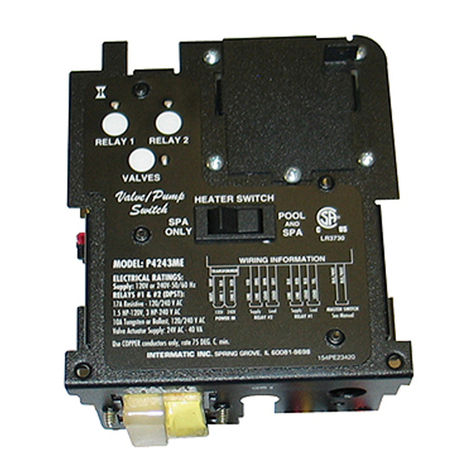

SYNCHRONIZATION

The actuator is not synchronized if it is rotating in the wrong

direction in respect to its controller or another actuator.

To test the synchronization of the system, connect the

actuator(s) to the controller and observe the function. If an

actuator is not synchronized, flip the 3-position toggle switch

at the rear of the actuator to the opposite position.

Synchronization Example

FIG. 4 represents the valves and actuators for a pool/spa

combination. The suction valve is plumbed the opposite

of the return valve. In this case, activating the actuators

turns one to the spa, while the other is turning to the pool.

The actuators need to be synchronized. To synchronize

the actuators, flip the toggle switch found at the rear of the

unsynchronized actuator to the opposite position. SeeFIG. 5.

Suction Return

Spa Pool SpaPool

FIG. 4. Synchronization Example

AUTO

ON 1

OFF

AUTO

ON 2

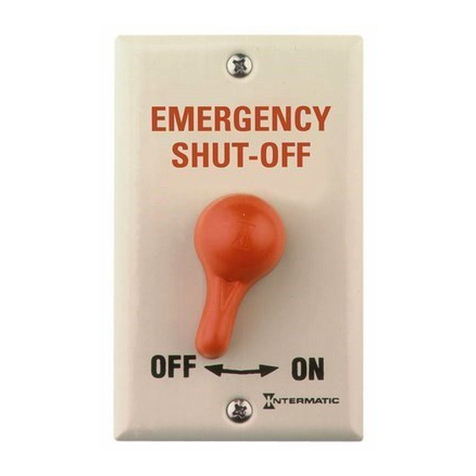

On/Off

Toggle Switch

on Back

of Actuator

FIG. 5. Toggle Switch