INSTALLATION

1. Remove the four #10 hex head screws from the

back of the enclosure and attach mounting brackets

to enclosure.

2. Select the proper location for the Control and hang

enclosure on a flat vertical surface or other support,

using hardware suitable for the purpose.

3. Prepare the necessary conduit runs, terminate them

at both ends and pull-in the conductors as specified

by the installation layout.

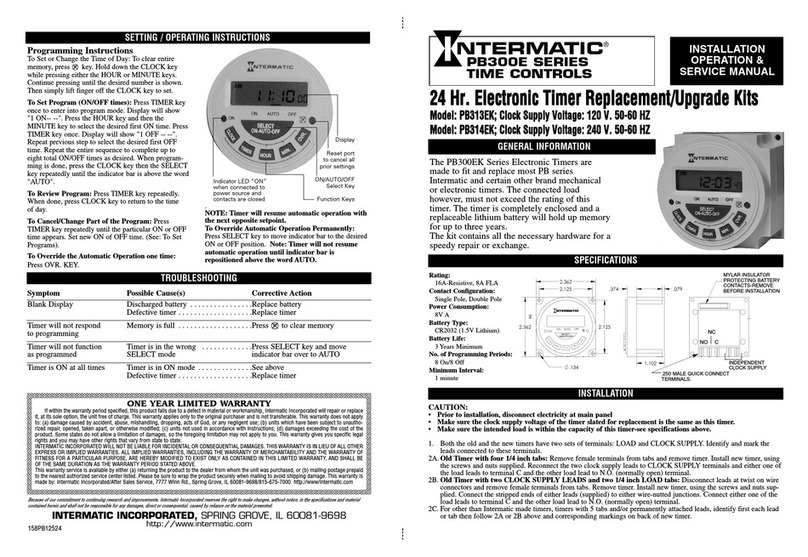

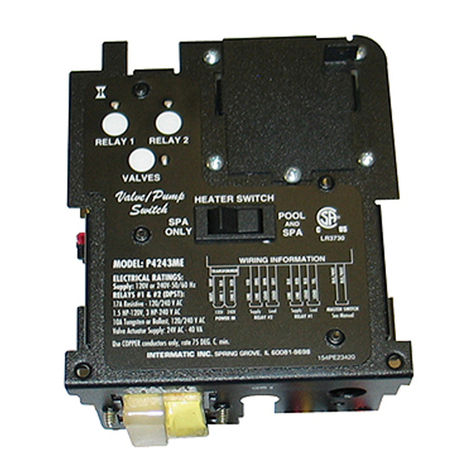

4. Refer to Figure 1 below. Note that this enclosure

contains two independent time switches. The one on

the left is a Model T106M, a Single Pole Double

Throw (SPDT) switch, and it’s function is to change

the speed (RPM) of the pump motor. The time

switch on the right is a Model T104M, a Double

Pole Single Throw (DPST) switch, and it’s

function is to start/stop the

pump motor. To wire the

two switches, follow wiring

diagram on page 4 of this

manual. Make sure that

connections to time switch terminals are tight

(25 lb. - in. minimum) and insulation clears the

pressure plate - see illustration.

a. Remove clock motor leads from Terminals A and 3 of

T106M and connect to Terminals 1 and 3 of T104M.

Connect LINE 1 to Terminal 1 and LINE 2 to Terminal 3

of T104M.

b. Install jumpers between Terminals 1 and 4 of T106M

and between Terminal 2 of T104M and Terminal 1 of

T106M.

c. Connect COMMON of Two Speed Pump to Terminal 4

of T104M, LOW to Terminal 2 of T106M and HIGH to

Terminal 3 of T106M.

d. Connect green grounding conductors to the Equipment

Grounding Terminal at bottom of enclosure.

5. If required by the heater manufacturer, install

fireman switch kit 156T4042A (not furnished) on

Time Switch Plate and make the fireman switch

connections.

Use at least #18

AWG wiring with

insulation rated

300 Volt or higher.

Place heater

ON/OFF switch

on heater to ON.

6. To install additional wiring devices inside the

enclosure, first remove rectangular knock-out(s) in

dead front. Next, remove hex head screws in back of

enclosure and install stand-offs* in place of screws.

Attach wiring device to stand-offs.

•Stand-offs are not furnished. Order 21T156A for a set of

four (4) stand-offs and mounting hardware.

7. If external bonding is required, install bonding lug(s)

on bottom of enclosure (156T11047A may be

ordered) and bond installation according to code

requirements.

8. Testing of the installation is optional and

recommended only if pump is securely in place

and will not be damaged by the following test:

a. Turn the manual level of the time switches to OFF.

b. Turn ON power at breaker panel.

c. Move the manual lever of T104M to the right (ON).

Pump should start and run on low speed.

d. Move the manual lever of T106M to the right (ON).

Pump should now be running on high speed.

e. Move the manual lever of T104M to the left (OFF).

Pump should stop running.

In case of unsatisfactory results, turn OFF power,

check your wiring, refer to Troubleshooting on Page 4.

9. Install front panel over wiring compartment.

The control is now ready for programming,

2

PRESSURE PLATE

TERMINAL SCREW

MAKE SURE INSULATION

CLEARS PRESSURE PLATE

Figure 1

PRESSURE PLATE

TERMINAL SCREW

MAKE SURE INSULATION

CLEARS PRESSURE PLATE

WARNING: Do not disconnect high limit or pressure switches.