inTest Temptronic ThermoChuck TP03000 Series Manual

Part Number:

41 Hampden Road, Mansfield, MA 02048 U.S.A.

Tel: +1.781.688.2300

www.inTESTthermal.com LM02350

TP03000

ThermoChuck®System

Operator’s Guide

Revision D

April 2011

TP03000 Operator’s Guide iii

. . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents

Preface

Copyright 2011 by Temptronic Corporation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii-vii

To Our Customers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii-vii

Temptronic Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii-viii

Before You Call. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii-ix

Declaration of Conformity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii-x

Chapter 1. Safety

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Chapter 2. Preparation For Use

Chapter Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Section A. Unpacking Information

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Section B. Installation Instructions

Section Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Placement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Interconnections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

ThermoChuck Platform Interconnections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

I/O Bus Interconnections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

ThermoJogger Interconnections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Emergency Off Interconnections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Interlock Interconnections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Section C. AC Power Input

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Section D. Repackaging

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Chapter 3. Local Operation

Chapter Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Section A. Start-Up Instructions

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Section B. Manual Mode Operations

Section Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Changing T1 and T2 Setpoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Changing TA Setpoint. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Changing T1, T2, and TA Windows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Operating at T1, T2, and TA Setpoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

TABLE OF CONTENTS

iv TP03000 Operator’s Guide

Section C. Program Mode Operations

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Section D. Automatic Mode Operations

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Chapter 4. Remote Interfaces

Chapter Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Section A. Remote Interfaces Introduction

Remote Interfaces Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Syntax Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Section B. Serial Interface (RS-232C)

Section Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Serial Interface Pin-Outs and Handshaking (RS-232C). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Serial Interface Parameters (RS-232C) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

-6

Serial Interface Control (RS-232C) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Serial Interface Commands (RS-232C) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Service Request, SRQ (RS-232C) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Section C. GPIB Interface (IEEE-488)

Section Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

GPIB Specifications (IEEE-488) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

GPIB Data Exchange Protocol (IEEE-488) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

GPIB Interface Parameters (IEEE-488) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

GPIB Control (IEEE-488) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

IEEE-488.1 Commands and Queries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

IEEE-488.2 Commands and Queries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

Service Request, SRQ (IEEE-488). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

Chapter 5. Routine Maintenance

Chapter Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Section A. Inspection and Cleaning

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Section B. Calibration

Section Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Verification Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Calibration Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Calibration Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Section C. Filling and Draining the Coolant Reservoir

Section Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Filling the Reservoir. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Draining the Reservoir . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Flushing the Coolant. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

Section D. Back-Up Battery Replacement

Section Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

Battery Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

Battery Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

. . . . .

TABLE OF CONTENTS

TP03000 Operator’s Guide v

Battery Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

Section E. Operating Diagnostics

Section Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

System Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

OVERHEAT Indications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

No AC Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

Error Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

TP03000 Controller:

Complete List of Mnemonic Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

Section F. Coolant Fitting Installation Recommendations

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-23

Section G. Identifying Damaged Flare Fittings

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-25

MSDS Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

TABLE OF CONTENTS

vi TP03000 Operator’s Guide

TP03000Operator’sGuide vii

. . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preface

Copyright 2011 by Temptronic Corporation

Notice

Patents have been granted and/or patent applications are pending or are in process of

preparation on all our developments.

The material in these instructions is for informational purposes and is subject to change

without notice.

Printed in U.S.A.

ThermoStream® is a registered trademark of Temptronic Corporation.

To Our Customers

This Manual The purpose of this manual is to help obtain the greatest return on your investment. Temptronic

suggests that operators, supervisors, and technicians responsible for operating and maintaining

this equipment become familiar with the contents of these manuals prior to using the

equipment.

PREFACE

Temptronic Support

viii TP03000 Operator’s Guide

Temptronic Support

Introduction Temptronic is committed to assisting end users and technicians to maintain operational

systems which are highly reliable. Temptronic offers the following support services.

Customer Training Formal technical training courses are available. The training courses cover the theory of

operation and the maintenance procedures for the System. For further information, contact the

Temptronic Service Department.

Repair Service Temptronic maintains a fully equipped repair center at the factory plant for warranty and non-

warranty repairs. For further information on module and circuit board repairs, our exchange

program, and the availability of spare parts, contact the Temptronic Service Department.

Before returning any module or circuit board for repair, contact the Temptronic Service

Department to obtain a return authorization (RA) number.

Spare Parts Electrical and mechanical replaceable parts for the System can be obtained through your local

Temptronic representative, or directly from the Temptronic Service Department. When

ordering, be sure to specify the:

• Quantity

• Temptronic part number

• Description

• Reference designation (if any)

• Complete model number and serial number of your system

For your convenience, Spare Parts Kits are available for different levels of service activity.

Technical Support Contact the Temptronic Service Department by one of the following means:

ATTENTION

1. Please note that the 1-800 toll free telephone number is dedicated to Service Department

calls only. It is not possible to dial this number and to transfer to other departments within

Temptronic.

2. The main telephone number, 781 688-2300, should be used for non-service related calls.

Temptronic Technical Support

1-800 558-5080 Toll Free Telephone (service calls only)

781 688-2302 Service FAX line

781 688-2300 Temptronic Corp. Main Telephone line

. . . . .

PREFACE

Before You Call

TP03000Operator’sGuide ix

Before You Call

Introduction You can help us support your machine in timely fashion by having on hand specific

information when calling in:

• Software Version

• System Model Number

System Model

Number A modular system design allows the customer to select options or features as desired for a

given installation or application

The System Model Number Designation, printed on the TP03000 nameplate, reflects the

configuration at time of shipment.

0930_101.jpg

PREFACE

Declaration of Conformity

x TP03000 Operator’s Guide

Declaration of Conformity

Document No.: LMS182440

ECO 110310 Rev.: D

Sheet 1 of 1

EC Declaration of Conformity

Manufacturer:

inTEST Thermal Solutions

41 Hampden Road

Mansfield, Massachusetts 02048

United States of America

Product Description:

Product Make: .............ThermoChuck®Thermal Inducing System

Model Number: ...........TP03000A, TP03010A,B, TP03015A,B, TP03020B

Year of Manufacture:...2011

Rating: .........................230V~, 50Hz, 10A

Serial Number:.............___________________________________

Directives and Standards:

73/23/EEC Low Voltage (LV) Directive

EN 60204-1:1997

EN 61010-1 (relevant aspects)

98/37/EC Machinery Directive, as specified in Annex I

EN ISO 12100-1 & 2 2003

EN 292-2:1991+A1:1995

89/336/EEC Electromagnetic Compatibility (EMC) Directive

EN55011:1998/A1:1999/A2:2002, EN61000-3-2:2000, EN61000-3-3:1995/A1:2001,

EN61326:1997/A1:1998/A2:2001

Equipment for Measurement, Control and Laboratory Use – General Use EMC Requirements

This confirmation is based on:

Test Report of: 30671412.002by TUV Rheinland of North America 2006

EG-0570-1 by Curtis-Straus LLC. 2006

Authorized Signature:

Printed Name: James Pelrin

Title: President

Date: March 29, 2011 Place: Mansfield, MA 02048 USA

TP03000 Operator’s Guide 1-1

1

. . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety

Introduction This Chapter covers all the safety Warnings and Cautions for the TP03000 ThermoChuck

System operators.

WARNINGS

WARNING

WAR NIN G: Operating personnel should perform only the procedures described and

recommended in this manual. Only qualified service personnel familiar with the electrical

shock hazards present in the equipment should be allowed to perform any disassembly or

corrective maintenance of the equipment. Only use the equipment for the intended usages

specified by the manufacturer.

WARNING

WAR NIN G: To avoid shock hazard, the equipment must be grounded with an adequate earth

ground per local electrical codes.

WARNING

WAR NIN G: A ThermoChuck should not be touched at temperatures lower than 10 °C or

higher than 40 °C.

WARNING

WAR NIN G: Dispose of any new or removed coolant fluid in accordance with established

polices and procedures for that material.

1SAFETY

1-2 TP03000 Operator’s Guide

CAUTIONS

CAUTION

CAUTION: Observe the precautions given on the equipment and within this manual to

prevent damage to the equipment. Only use the equipment for the intended usages specified by

the manufacturer.

CAUTION

CAUTION: Use proper handling and packaging procedures for static-sensitive circuit boards.

Assume that all circuit boards are the static-sensitive type.

CAUTION

CAUTION: Upon initial installation of the equipment, verify that the voltage and frequency

on the serial tag at the Controller rear panel match the ratings of the power source to be used

for the TP03000A System.

CAUTION

CAUTION: Do not place anything on the ThermoChuck surface that cannot withstand the

upper temperature limit of +130 °C (or +200 °C when option).

CAUTION

CAUTION: A ThermoChuck surface is typically gold plated. Do not use any (harsh) abrasive

materials for cleaning.

CAUTION

CAUTION: Do not overfill with coolant – the coolant system must have room for expansion

of the coolant at high operating temperatures.

CAUTION

CAUTION: Make sure the Controller power cord is disconnected from its power source

before replacing the back-up batteries for RAM storage.

TP03000 Operator’s Guide 2-1

2

. . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preparation For Use

Chapter Overview

Introduction This chapter provides unpacking and setup information for the TP03000 ThermoChuck

System.

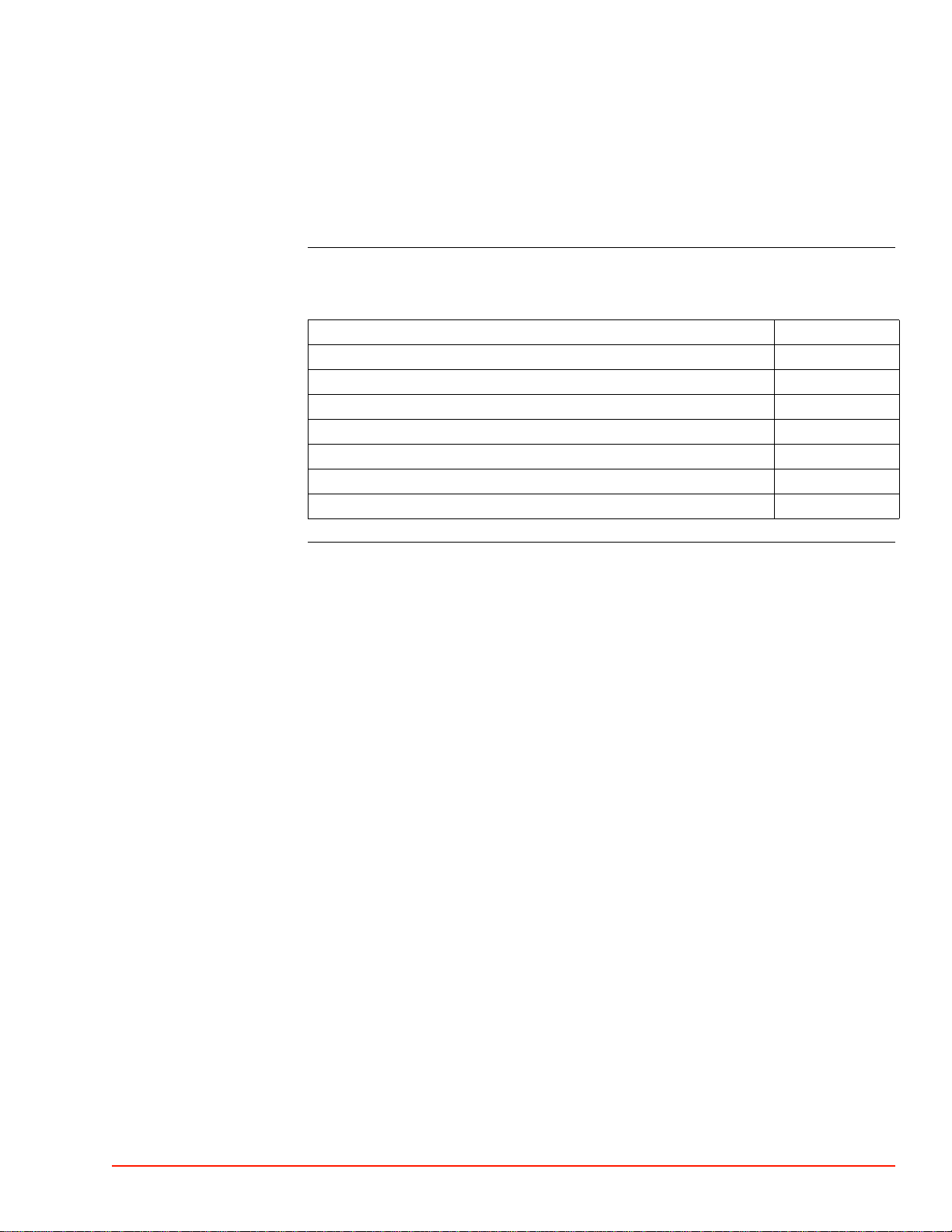

In this Chapter This Chapter is divided into the following Sections:

Section See Page

Unpacking Information 2

Installation Instructions 3

AC Power Input 9

Repackaging 10

2PREPARATION FOR USE

2-2 TP03000 Operator’s Guide

Section A:

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unpacking Information

Introduction The TP03000 ThermoChuck System is shipped to you in one container. All purchased items

are included. When received, examine the container for any signs of mishandling or damage

during shipment.

NOTE: If you see any obvious signs of damage to the package, contact the carrier

immediately and do not proceed with the installation. Since the shipment is made FOB factory,

you should consult your administration concerning claims for shipping damage.

CAUTION

CAUTION: Packaging materials may be a source for ESD potential. Do not unpack in the

vicinity of ESD sensitive components.

When unpacking the system, save all packaging material in the event the system has to be

reshipped later. After the system has been unpacked, the following visual inspections should be

made:

1. Verify that all items purchased are received.

2. Verify that the indicators and switches are in place and intact.

3. Check that all cable connectors are tightly seated.

4. Verify that all chassis/cabinet mounting hardware is secure.

5. Check that the ThermoChuck Platform (individually packed) is not scratched or damaged.

. . . . .

PREPARATION FOR USE

Section Overview

TP03000 Operator’s Guide 2-3

Section B:

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation Instructions

Section Overview

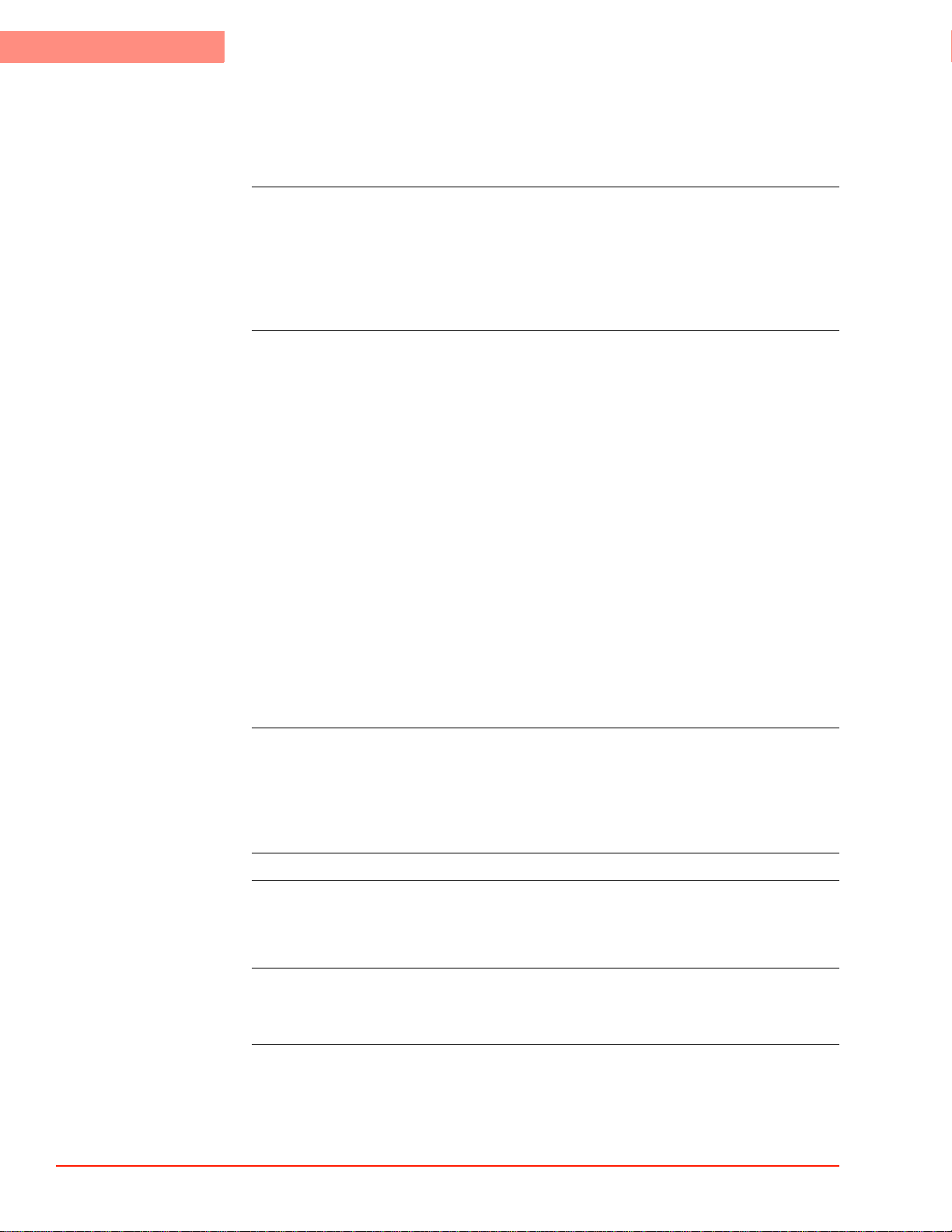

In this Section The following topics are covered in this Section:

Topic See Page

Placement 4

Interconnections 5

ThermoChuck Platform Interconnections 6

I/O Bus Interconnections 7

ThermoJogger Interconnections 7

Emergency Off Interconnections 7

Interlock Interconnections 8

2PREPARATION FOR USE

Placement

2-4 TP03000 Operator’s Guide

Placement

The TP03000 System should be located near the test system and a grounded ac power outlet to

avoid stressing the electrical cables and coolant lines during operation.

• The Controller requires an 8-inch (203-mm) rear clearance for cables and air flow.

• The Cooler/Circulator requires 12-inch (305-mm) front and rear clearances for cables,

hoses, and air flow.

A grounded outlet from the ac power source must be located within 10 feet (2.5 m) of the

Controller rear panel for the system input.

If you mount the TP03000 System in a rack, make sure it can support the 160-pound (72.6-kg)

Cooler/ Circulator when pulled out on its slides (30-inch, 762-mm, travel) without causing any

equipment or personnel hazard.

Also, be sure the equipment slides for mounting the Controller and the Cooler/ Circulator are

attached to rear rails in the rack for adequate support. Temptronic provides threaded mounting

holes for mounting the TP03000 System components in the following rack slides:

0930_201.jpg

If required and purchased, hardware and installation instructions are provided to interface the

ThermoChuck Platform to most standard probers. In some cases, the ThermoChuck Platform

(sometimes called chuck) is specially configured to be an integral part of the Z-stage in the

prober.

. . . . .

PREPARATION FOR USE

Interconnections

TP03000 Operator’s Guide 2-5

Interconnections

Perform the following before making the system interconnections:

1. Check that MAIN POWER circuit breaker on the Controller rear panel is in the ON posi-

tion.

2. Check that system power switch on Controller front panel is at the off (0) position.

3. Verify that cable is in place between COOLER connector on Controller rear panel and

CONTROL INPUT connector on Cooler/Circulator rear panel.

4. Verify that FILL and VENT ports are covered with caps at Cooler/Circulator rear panel.

These caps must be installed to prevent moisture from collecting inside the coolant system

and causing the system to malfunction. Remove these caps only during coolant filling or

draining.

2PREPARATION FOR USE

ThermoChuck Platform Interconnections

2-6 TP03000 Operator’s Guide

ThermoChuck Platform Interconnections

1. Mount the ThermoChuck Platform to your prober stage.

2. Connect the supplied coolant lines to the ThermoChuck Platform.

ATTENTION

NOTE: The coolant lines and fittings are Teflon; tighten the ferrule sleeve portion by hand

only

do not over tighten. Carefully tighten the pipe thread portion with a wrench.

Refer to Chapter 5: Coolant Fitting Installation Recommendations as needed.

3. Use a CEE (Controlled Environmental Enclosure [dry box]) for continuous ThermoChuck

Platform operation below +40 °C.

NOTE: The TP03000 System pumps approximately -50 °C coolant through the ThermoChuck

heat sink to dissipate waste heat from the solid-state cooling devices to prevent an overheat

condition. USE OF A CEE PREVENTS CONDENSATION AND/OR FROST FROM

FORMING ON THE COOLANT LINES, since the fluid inside the coolant lines is below the

ambient temperature dew point.

When the system is not being used for temperature testing but left running with the

ThermoChuck exposed to ambient it is recommended to set the temperature control to +40°C

to turn the pump OFF stopping the coolant flow so frost and condensation will not form on the

ThermoChuck and coolant lines.

4. Plug the control cable from the ThermoChuck Platform into the THERMAL DEVICE

connector on the Controller rear panel.

5. Connect one coolant line from the ThermoChuck Platform into the SUPPLY port on the

Cooler/ Circulator rear panel.

6. Connect the other coolant line from the ThermoChuck Platform into the RETURN port on

the Cooler/Circulator rear panel.

ATTENTION

NOTE: The TP03000 is shipped dry without any coolant. The coolant is added as the System

is operated for the first time. After the System is placed in operation, inspect the coolant

fittings routinely for leaks. Extra fittings are supplied in the event of damage.

CAUTION

CAUTION: Do not operate the TP03000 System without any coolant.

7. Connect the vacuum line (supplied) from the ThermoChuck Platform's port to a vacuum

supply.

. . . . .

PREPARATION FOR USE

I/O Bus Interconnections

TP03000 Operator’s Guide 2-7

I/O Bus Interconnections

1. Use the cable connector supplied for the I/O connector (IEEE or RS232) on the Controller

rear panel to make interface connections to the remote computer bus.

2. Wire the pin connections for the type interface to be used. Chapter 4 provides greater

detail for Remote Interfaces includes pin identifications for the RS-232C and IEEE-488

interface.

ThermoJogger Interconnections

1. For the ThermoJogger option, make sure the ThermoJogger hand controller is the new

type (intended for a TP03000A-X300, TP03000A-0301, or TP03020B-2300 Systems).

2. Plug the cable supplied with the ThermoJogger hand control into the JOG connector on

the Controller rear panel.

Emergency Off Interconnections

1. For this feature, use the cable connector supplied for the EMO connector on the Controller

rear panel to make connections to the external switch in the test system.

2. Remove the wire jumper between pins 1 and 2 and connect the two cable leads from the

external switch (must be rated for 24 Vac at 1 A, minimum). (Switch contacts must be

closed for TP03000 operation; opened during emergency off.)

ATTENTION

NOTE: Either the wire jumper must be installed in the EMO cable connector or pins 1 and 2

must be a closed circuit through the external switch for operation of the TP03000 system.

2PREPARATION FOR USE

Interlock Interconnections

2-8 TP03000 Operator’s Guide

Interlock Interconnections

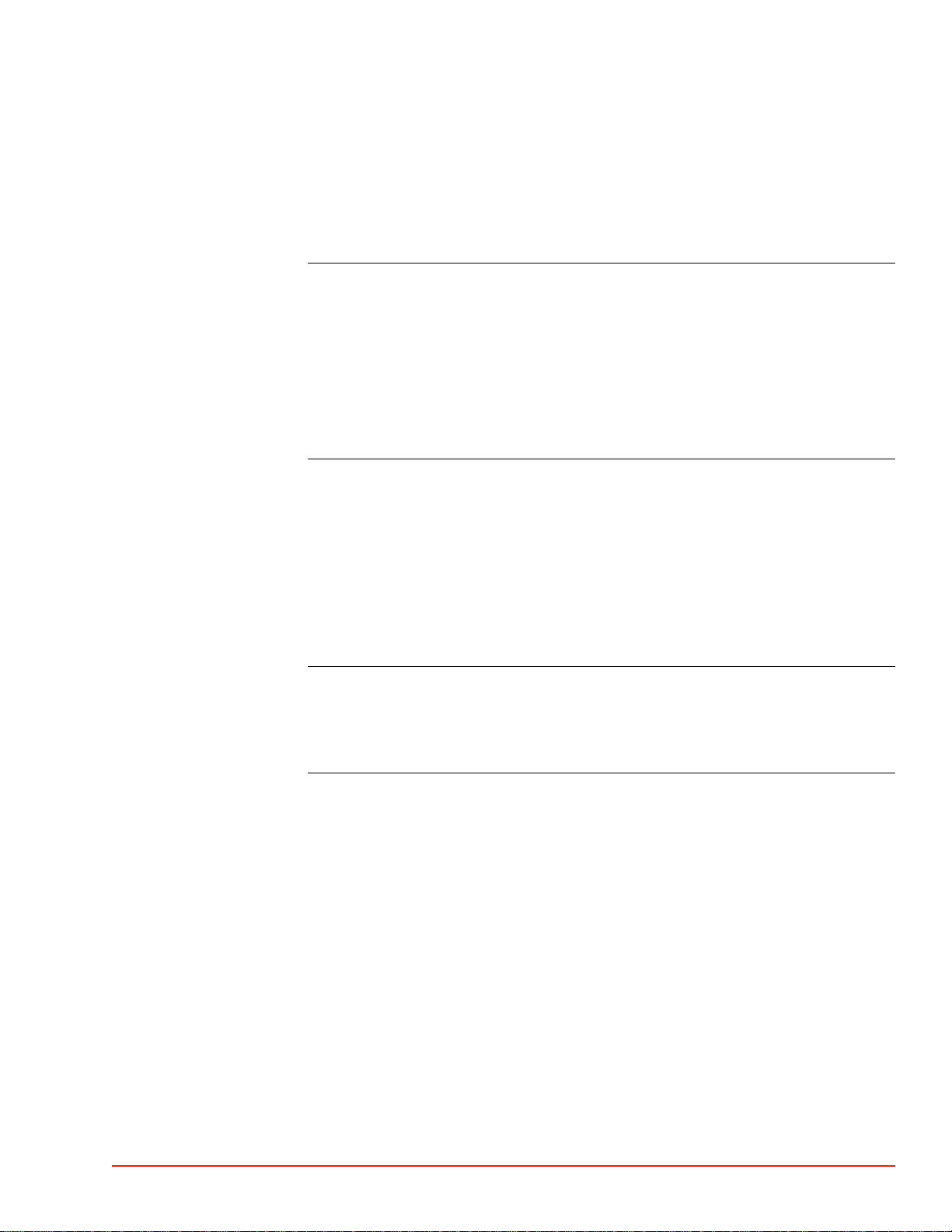

The system rear panel includes a nine-pin connector for the INTERLOCK connections. The

mating connector and pins (Interlock plug kit P/N SA73990) are supplied at the time of

shipment.

NOTE: The pin extractor tool is AMP Incorporated P/N 91067-2.

The interlock feature can be used to lock an access door/panel on an enclosure that houses the

ThermoChuck Platform when its surface temperature exceeds 70 °C. The interlock is a relay

closure that is controlled by the system microprocessor. The relay contacts toggle from

normally open to normally closed when the ThermoChuck surface temperature goes above 70

°C. The user must supply the interlock signal, which should not exceed 24 volts, 5 amperes.

0930_204.jpg

This manual suits for next models

6

Table of contents

Popular Industrial Equipment manuals by other brands

Flott

Flott TS 150 SW operating instructions

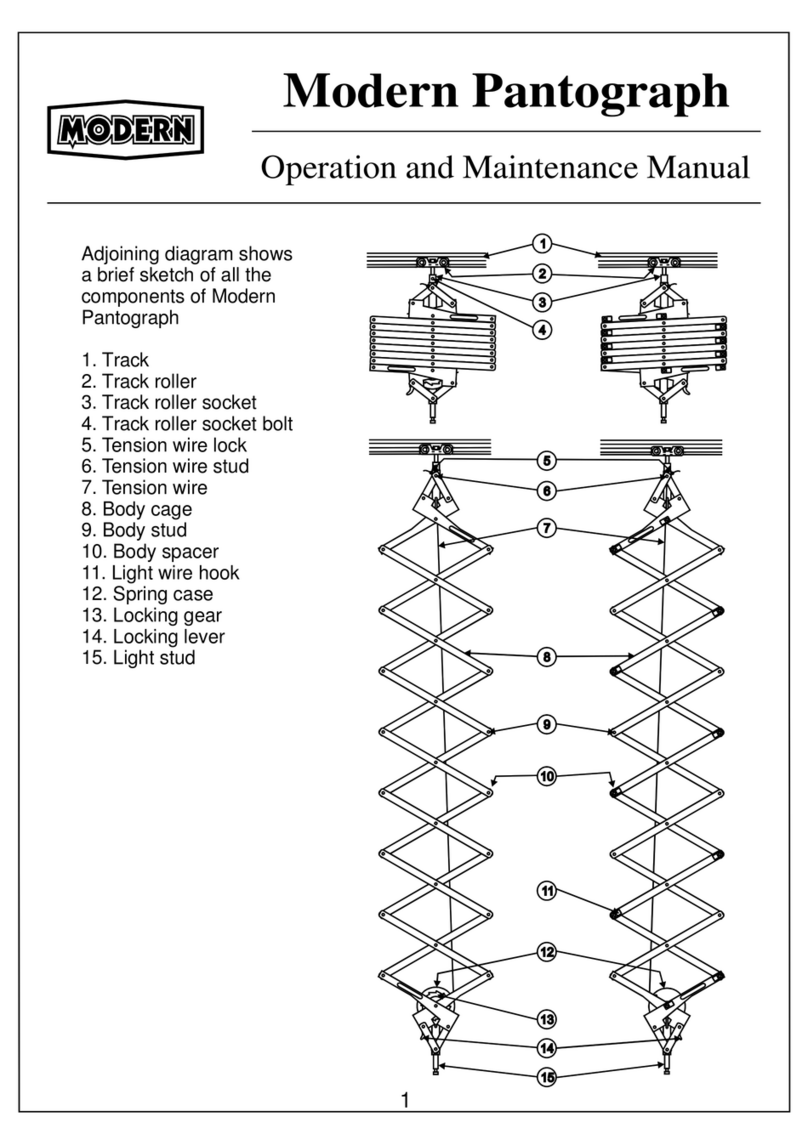

Modern

Modern Pantograph Operation and maintenance manual

Eastern Energy

Eastern Energy DuraSite 3000 user guide

Rodix

Rodix FEEDER CUBE FC-41-480 Series ADJUSTMENTS & SET UP

Keison

Keison Bibby Scientific Techne Afterburners AB-100 Operator's manual

vc999

vc999 K4 Operating instruction

Southwestern Industries

Southwestern Industries TRAK TMC5 Safety, Installation, Maintenance, Service and Parts List

ASO Safety Solutions

ASO Safety Solutions SENTIR mat instruction manual

ABB

ABB HT607894 Operation manual

HBK

HBK HLCM Mounting instructions

Grizzly

Grizzly G0714 owner's manual

VersaBuilt

VersaBuilt Robot2CNC Installation and operation