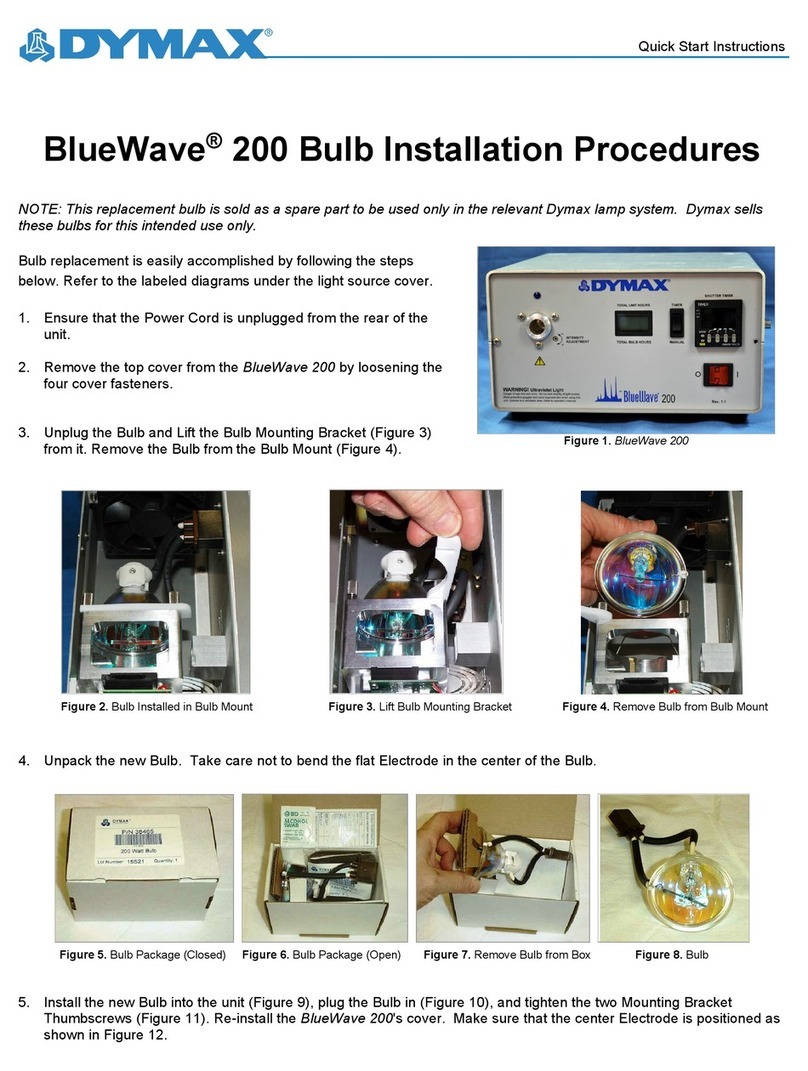

INSTALLATION AND SYSTEM INTERCONNECT

1. Connect the Power Cord to the Power Receptacle on the rear of

the unit and plug the Power Cord into a grounded wall outlet.

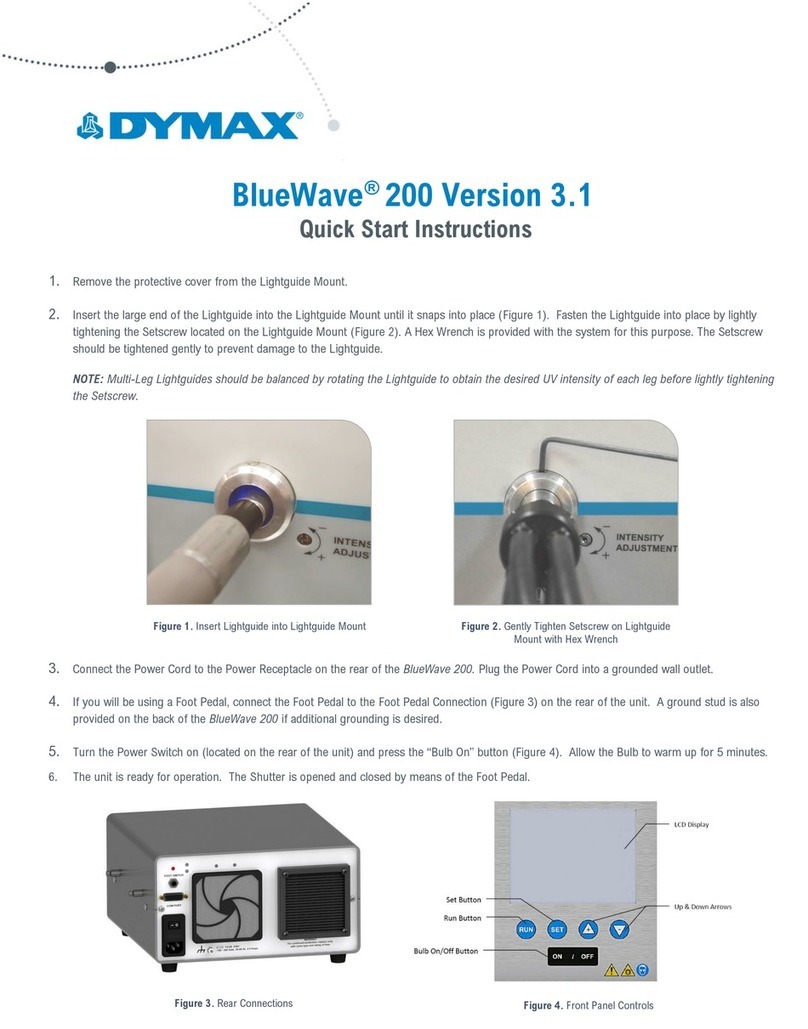

Figure 3. Cable Connection,

BlueWave 200 Rear Panel

Figure 4. Lightguide Mount

Protective Cover Installed (left);

Protective Cover Removed (right)

Figure 5. Insert Lightguide into

Lightguide Mount

Figure 6. Adjust the Intensity Adjustment

Screw

Footswitch

Connection

Power

Receptacle

Power Cord

2. Connect the Footswitch to the Footswitch Connection (Figure 3)

in the rear of the unit. A ground stud is provided on the back of

the unit if additional grounding is desired.

3. Remove the protective cover from the BlueWave®200’s

Lightguide Mount (Figure 4).

NOTE: Always have a Lightguide or the protective cap engaged

in the Lightguide Mount. UV light can escape when the Shutter is

activated.

4. Remove the protective end caps from the Lightguide. Visually

inspect the two ends of the Lightguide to verify that no foreign

material is present. The ends of a DYMAX liquid-filled Lightguide

can be cleaned with isopropyl alcohol as required to remove

foreign material and deposition from outgassing.

5. Insert the large end of the Lightguide into the Lightguide Mount

until it snaps into place (Figure 5).

6. If desired, the Lightguide may be fastened into place by lightly

tightening the securing setscrew installed in the Lightguide

Mount (Figure 6). A hex wrench is provided with the BlueWave

200 for this purpose. The setscrew should be tightened gently to

prevent damaging the Lightguide.

NOTE: Multi-leg Lightguides should be balanced by rotating the

Lightguide to obtain the desired UV intensity of each leg before

tightening the setscrew.

7. Turn the BlueWave 200's Power Switch on.

8. Allow the Bulb to warm up 4-5 minutes to obtain the maximum

light output.

CAUTION: This is an arc, not a filament Bulb. Once ignited, it

must be left on for a minimum of 10 minutes to fully vaporize

elements in the Bulb. If not, the Bulb may be difficult to re-ignite.

Each re-ignition increases the rate of Bulb degradation.

NOTE: The Bulb must cool before it can be re-ignited. Turn the

unit off and allow 5 to 10 minutes for it to cool down. If the Bulb

fails to ignite, refer to the Troubleshooting Section of this manual.

Bulb life is reduced each time the unit is switched on and off.

Avoid repeated cycles that shorten Bulb life by leaving unit on

through breaks.

9. Operate the Shutter by pressing the Footswitch. With the Shutter

Selector Switch in the manual position, the Shutter operates

directly from the Footswitch. In the timed position, the Shutter

opening is determined by the setting on the electronic Timer.

Simply push the Timer Setting Buttons to enter the desired

number of seconds the Shutter is to remain open.

10. With the Shutter open, adjust the Intensity Adjustment Screw as

required to achieve the desired output intensity (Figure 6).

10 DYMAX BlueWave®200 Version 1.1 UV Light-Curing Spot Lamp System