INTORQ BFK468 User manual

Other INTORQ Spring Applied Brake manuals

INTORQ

INTORQ BFK471-25 Quick guide

INTORQ

INTORQ BFK458 User manual

INTORQ

INTORQ BFK470 Series Quick guide

INTORQ

INTORQ BFK458-ATEX Quick guide

INTORQ

INTORQ BFK464-R Series Quick guide

INTORQ

INTORQ BFK455 User manual

INTORQ

INTORQ BFK455-25 Quick guide

INTORQ

INTORQ BFK468 User manual

INTORQ

INTORQ 14.105 Series User manual

INTORQ

INTORQ BFK457 Series User manual

Popular Spring Applied Brake manuals by other brands

Kendrion

Kendrion 76..P..B00 Series operating instructions

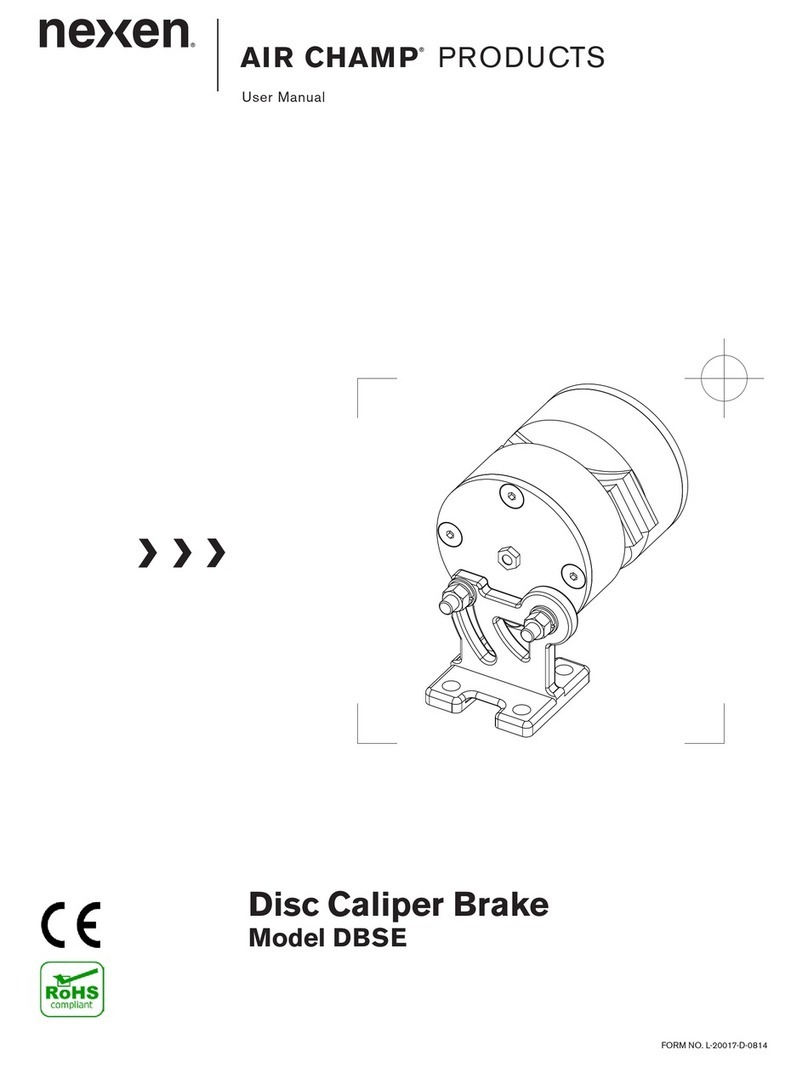

Nexen

Nexen AIR CHAMP DBSE user manual

Kendrion

Kendrion EEX Series operating instructions

Leantechnik

Leantechnik SHB Series operating instructions

Kobelt

Kobelt 5022-A Owner's Operation, Installation & Maintenance Manual

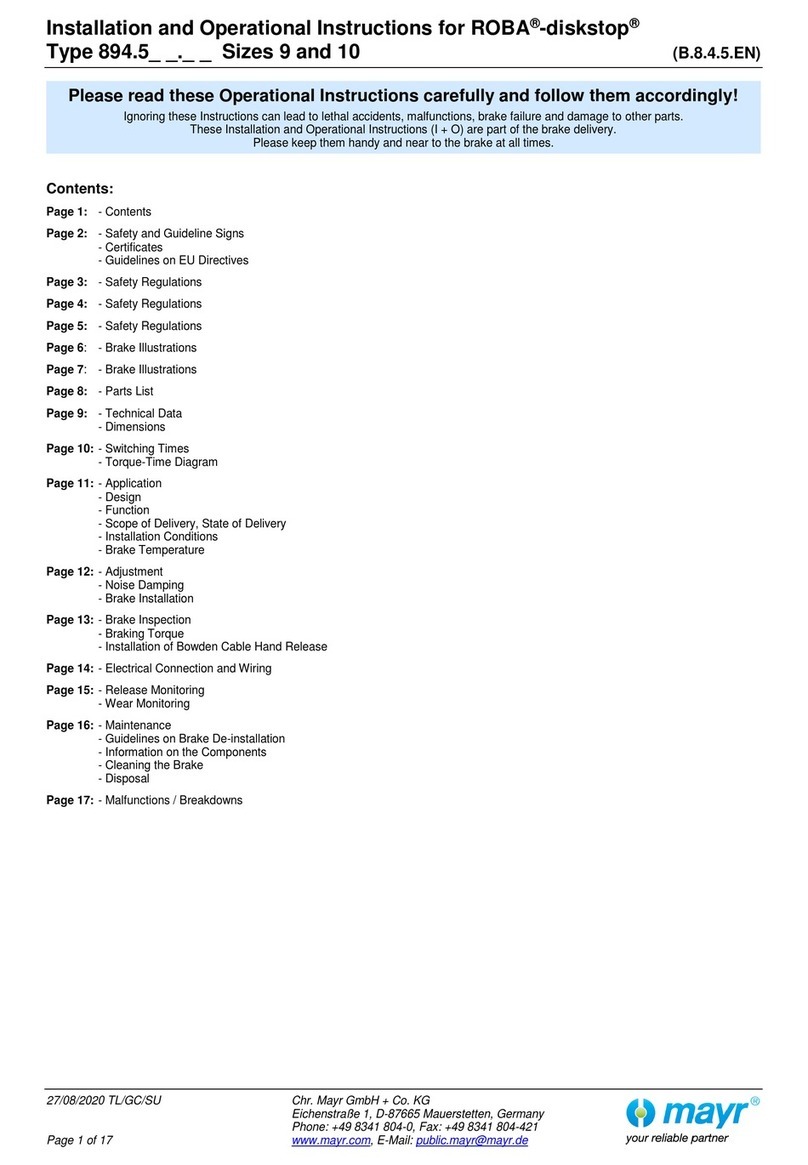

Mayr

Mayr ROBA-stop-M 250 Operational instructions

COREMO OCMEA

COREMO OCMEA E4N-ID User and maintenance manual

Nexen

Nexen AIR CHAMP DPB-9T user manual

Mayr

Mayr ROBA-diskstop 894.5 Series Installation and operational instructions

WABCO

WABCO PAN 17 Assembly and maintenance instructions

Kendrion

Kendrion INTORQ BFK458-ATEX Original operating instructions

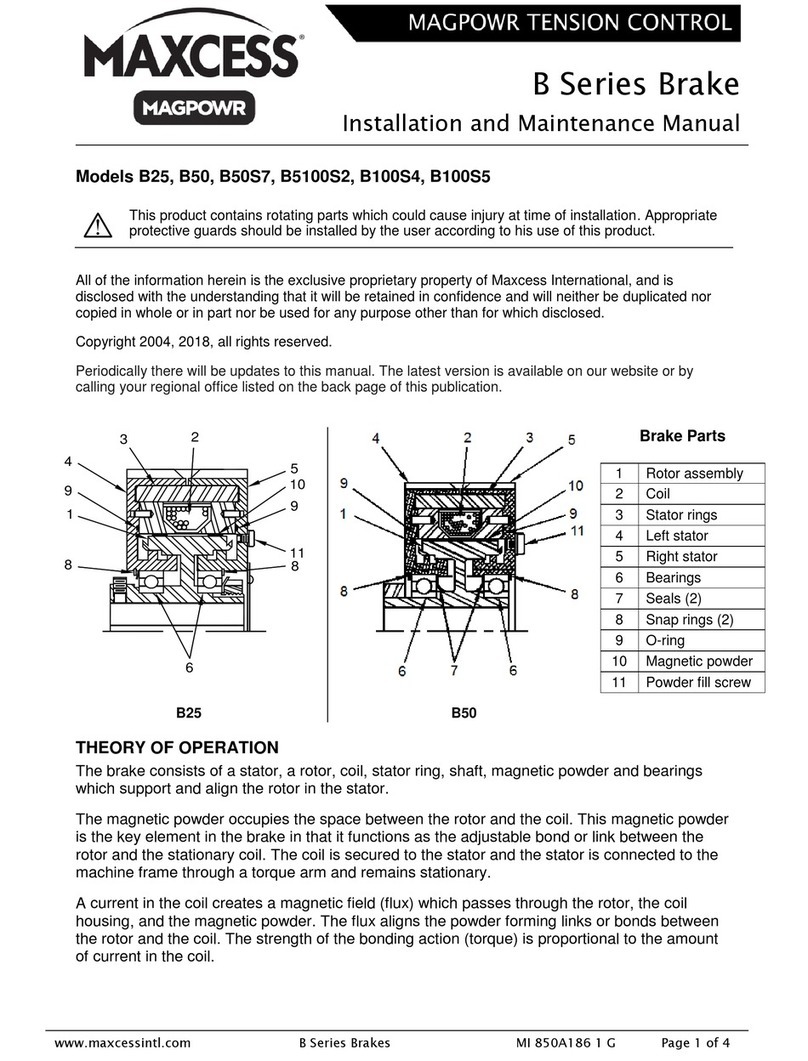

Maxcess

Maxcess MAGPOWR B Series Installation and maintenance manual

Haldex

Haldex Maxibrake 50 Series Service parts

Kendrion

Kendrion INTORQ BFK551 Translation of the original operating instructions

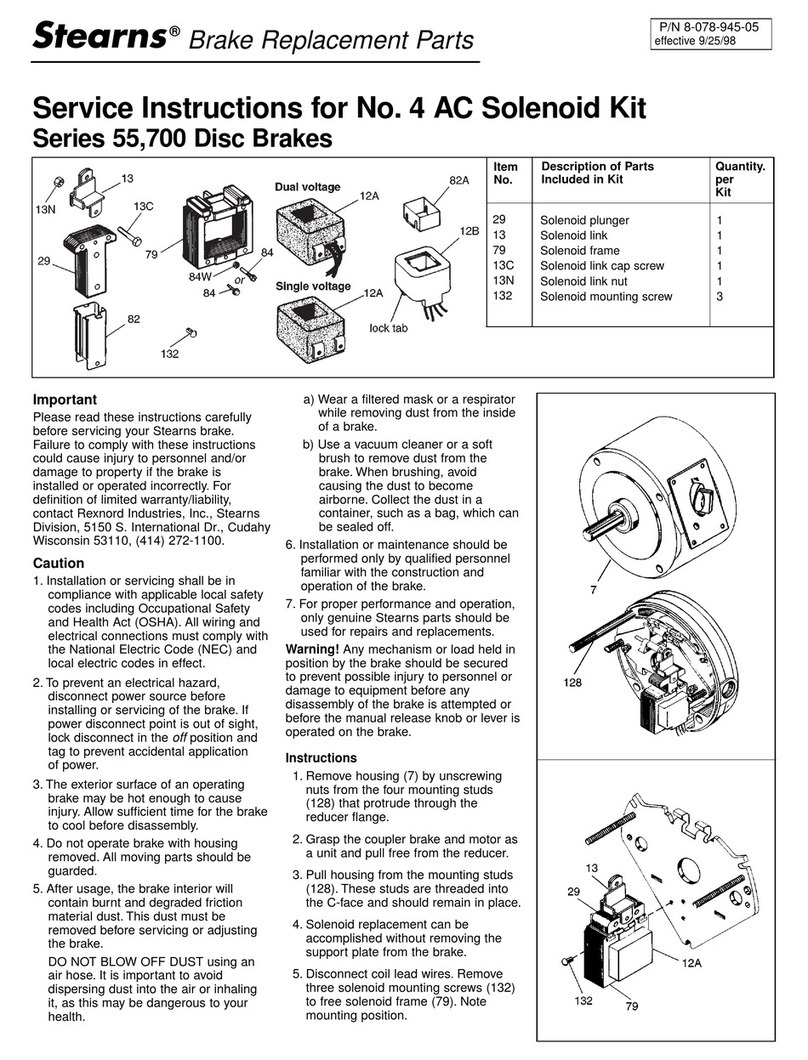

Rexnord Industries

Rexnord Industries Stearns 55,700 Series quick start guide

Rexnord Industries

Rexnord Industries Stearns 57,000 Series Service instructions

Alligator

Alligator Gatorbrake 6 Piston Installation and service manual

COREMO OCMEA

COREMO OCMEA G-M User and maintenance manual