Content IV

Content

Foreword ...................................................................................................................................................................I

Safety instructions ..................................................................................................................................................II

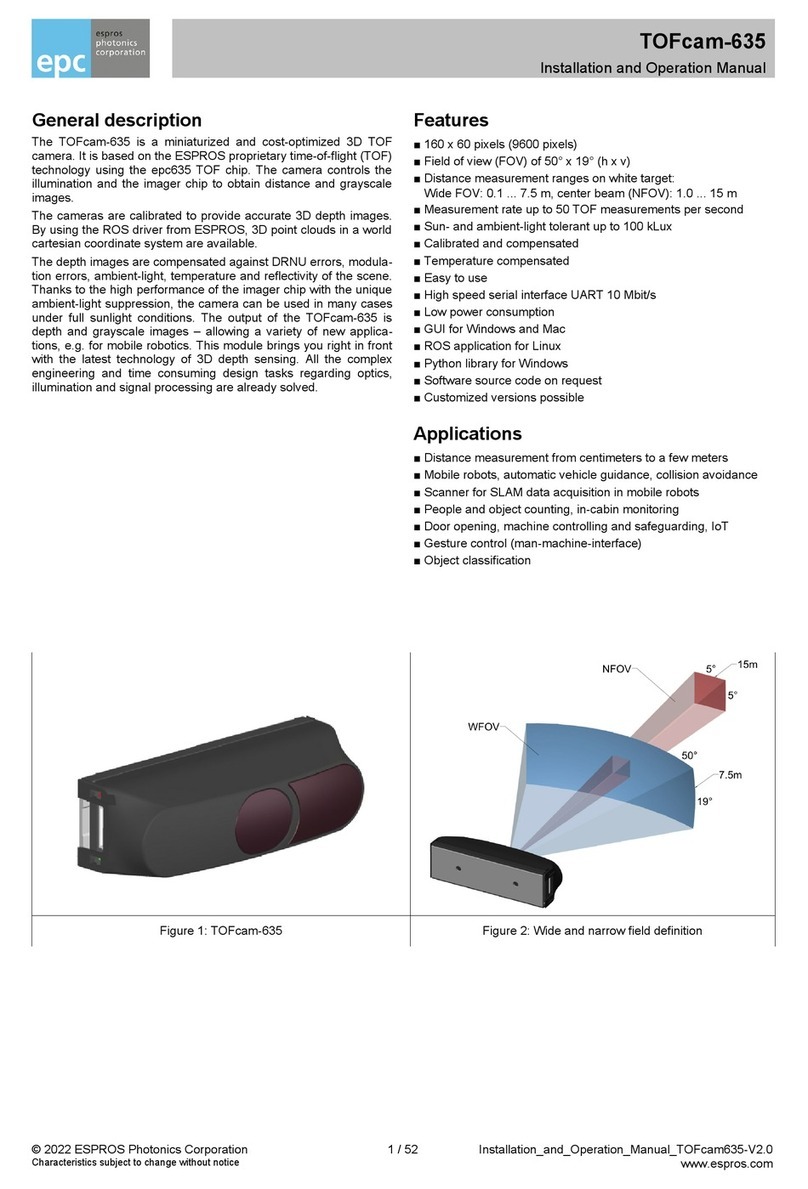

1 Product introduction ............................................................................................................................................ 1

1.1 Product introduction .................................................................................................................................... 1

1.2 Product feature............................................................................................................................................. 2

1.3 Packing list .................................................................................................................................................. 3

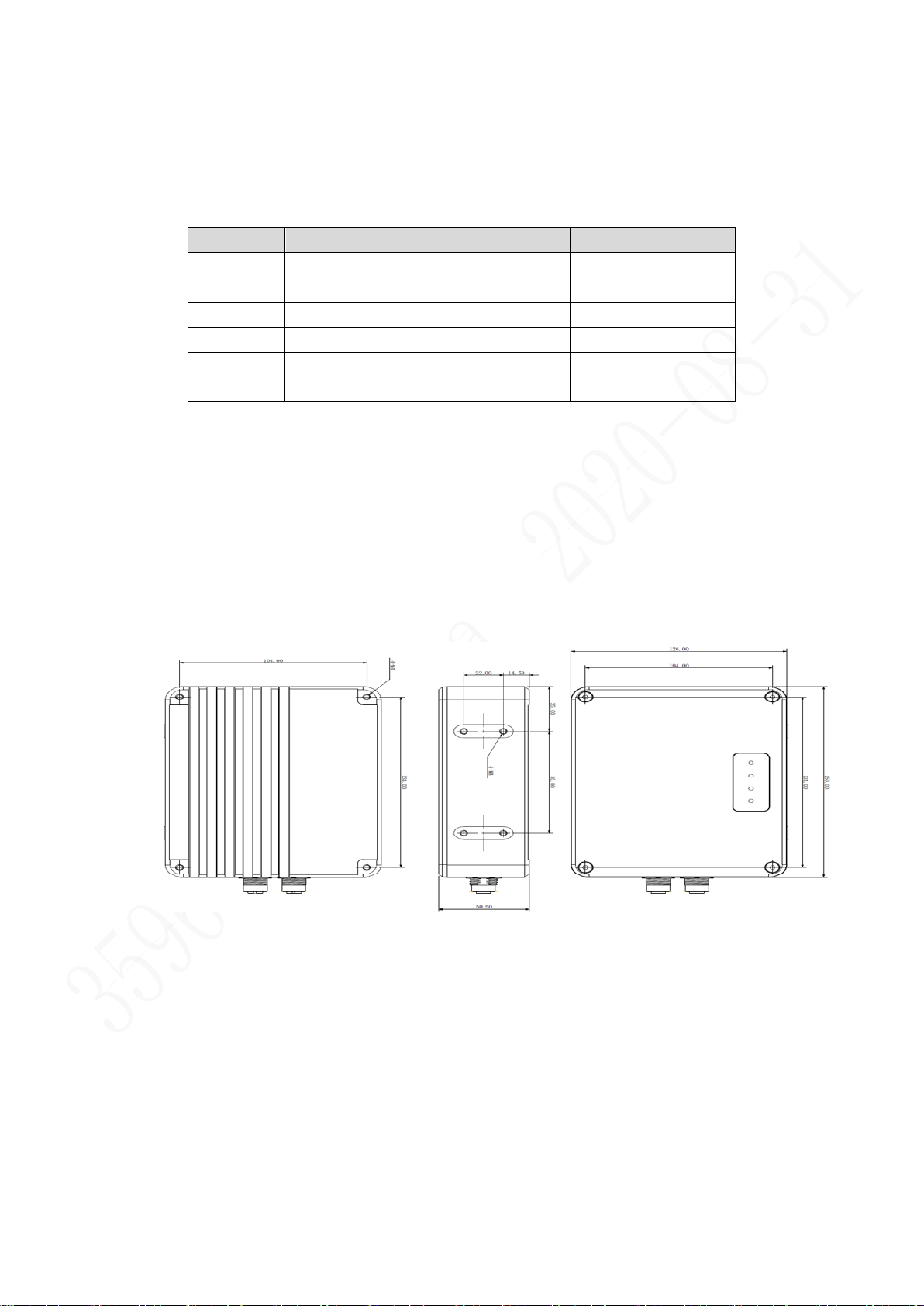

1.4 Product structure.......................................................................................................................................... 3

1.4.1 Product dimension............................................................................................................................ 3

1.4.2 Product interface............................................................................................................................... 4

1.5 Electrical specification................................................................................................................................. 7

2 Network............................................................................................................................................................... 17

3 Product installation ............................................................................................................................................ 18

4 Camera operation............................................................................................................................................... 19

4.1 Install the client.......................................................................................................................................... 19

4.2 Configuration guidance ............................................................................................................................. 20

4.3 Connect and disconnect the camera........................................................................................................... 21

4.4 The camera functions................................................................................................................................. 22

4.5 Image display............................................................................................................................................. 23

5 Camera functions................................................................................................................................................ 26

5.1 DeviceControl............................................................................................................................................ 26

5.2 TransportLayerControl .............................................................................................................................. 27

5.3 NTPcontrol ................................................................................................................................................ 28

5.4 TriggerControl........................................................................................................................................... 29

5.5 MonoCameraControl................................................................................................................................. 29

5.5.1 MonoCameraISPControl ................................................................................................................ 30

5.5.2 MonoCameraExposureControl....................................................................................................... 30

5.5.3 MonoImageFormatControl............................................................................................................. 31

5.6 ColorCameraControl.................................................................................................................................. 31

5.6.1 ColorCameraISPControl................................................................................................................. 32

5.6.2 ColorCameraExposureControl........................................................................................................ 32

5.6.3 ColorImageFormatControl.............................................................................................................. 33

5.7 VisionControl............................................................................................................................................. 33

5.8 BinocluarControl ....................................................................................................................................... 34

5.9 3DLocationControl.................................................................................................................................... 35

5.10 Digital IO Control.................................................................................................................................... 36

5.11 InputIOControl......................................................................................................................................... 37

5.12 LaserControl............................................................................................................................................ 37

5.13 UserSetControl ........................................................................................................................................ 38