Reference Manual

Ranger E/D

4©SICK AG • Advanced Industrial Sensors • www.sick.com • All rights reserved

Contents

5.6 Setting Exposure Time...........................................................................................................47

5.7 Range Measurement Settings ..............................................................................................49

5.8 Details on 3D Profiling Algorithms........................................................................................ 50

5.9 Color Data Acquisition ...........................................................................................................54

5.9.1 White Balancing .......................................................................................................54

5.9.2 Color Channel Registration...................................................................................... 55

5.10 Calibration.............................................................................................................................. 56

5.10.1 Calibrated Data ........................................................................................................57

5.10.2 Rectified Images ...................................................................................................... 57

5.10.3 Physical Setup.......................................................................................................... 58

5.10.4 Calibration and 3D Cameras ...................................................................................59

6Ranger D Parameters .................................................................................................................61

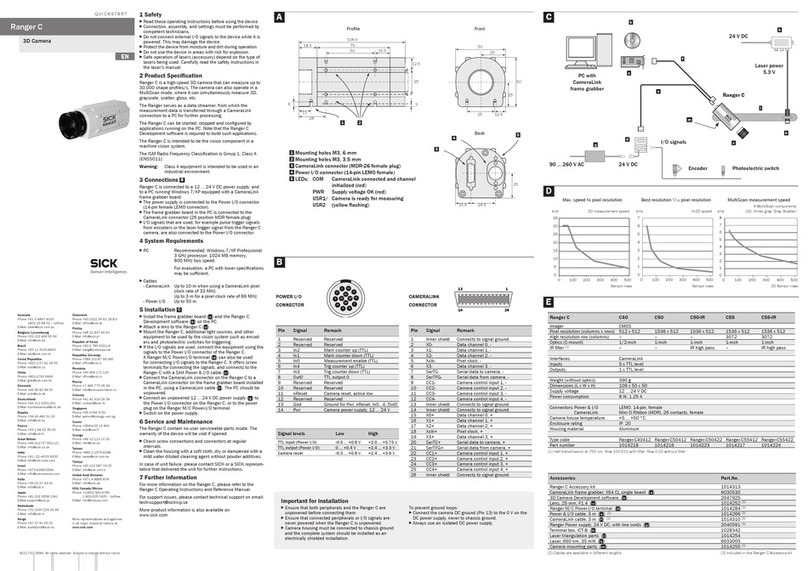

6.1 System settings .....................................................................................................................61

6.2 Ethernet Settings...................................................................................................................61

6.3 Image Configuration ..............................................................................................................62

6.4 Measurement Configuration .................................................................................................63

7Ranger E Parameters..................................................................................................................67

7.1 System settings .....................................................................................................................67

7.2 Ethernet Settings...................................................................................................................67

7.3 Image Configuration ..............................................................................................................68

7.4 Measurement Configuration .................................................................................................70

7.5 Measurement Components ..................................................................................................72

7.5.1 Horizontal Threshold (HorThr) .................................................................................72

7.5.2 Horizontal Max (HorMax) .........................................................................................76

7.5.3 Horizontal Max and Threshold (HorMaxThr) ...........................................................77

7.5.4 High-resolution 3D (Hi3D)........................................................................................79

7.5.5 High-resolution 3D (Hi3D COG) ...............................................................................80

7.5.6 Gray ..........................................................................................................................83

7.5.7 HiRes Gray................................................................................................................ 84

7.5.8 Scatter ......................................................................................................................85

7.5.9 Color and HiRes color ..............................................................................................86

8iCon API ....................................................................................................................................... 89

8.1 Connecting to an Ethernet Camera ......................................................................................90

8.2 Retrieving Measurement Data.............................................................................................. 92

8.2.1 IconBuffers, Scans, Profiles and Data Format .......................................................92

8.2.2 Accessing the Measurement Data ..........................................................................93

8.2.3 Polling and Call-back ...............................................................................................95

8.2.4 Handling Buffers ......................................................................................................95

8.2.5 Mark Data.................................................................................................................96

8.3 Changing Camera Configuration...........................................................................................97

8.3.1 Using Parameter Files.............................................................................................. 97

8.3.2 Setting Single Parameter Values.............................................................................97

8.4 Error Handling........................................................................................................................98

8.5 Calibration and Post Processing of Buffers.......................................................................... 99

8.5.1 Filter Classes............................................................................................................99

8.5.2 Extraction Filter ......................................................................................................100

8.5.3 Calibration Filter.....................................................................................................100

8.5.4 Rectification Filter..................................................................................................101

8.5.5 Color Registration filter..........................................................................................101

8.5.6 Color Generation Filter...........................................................................................103