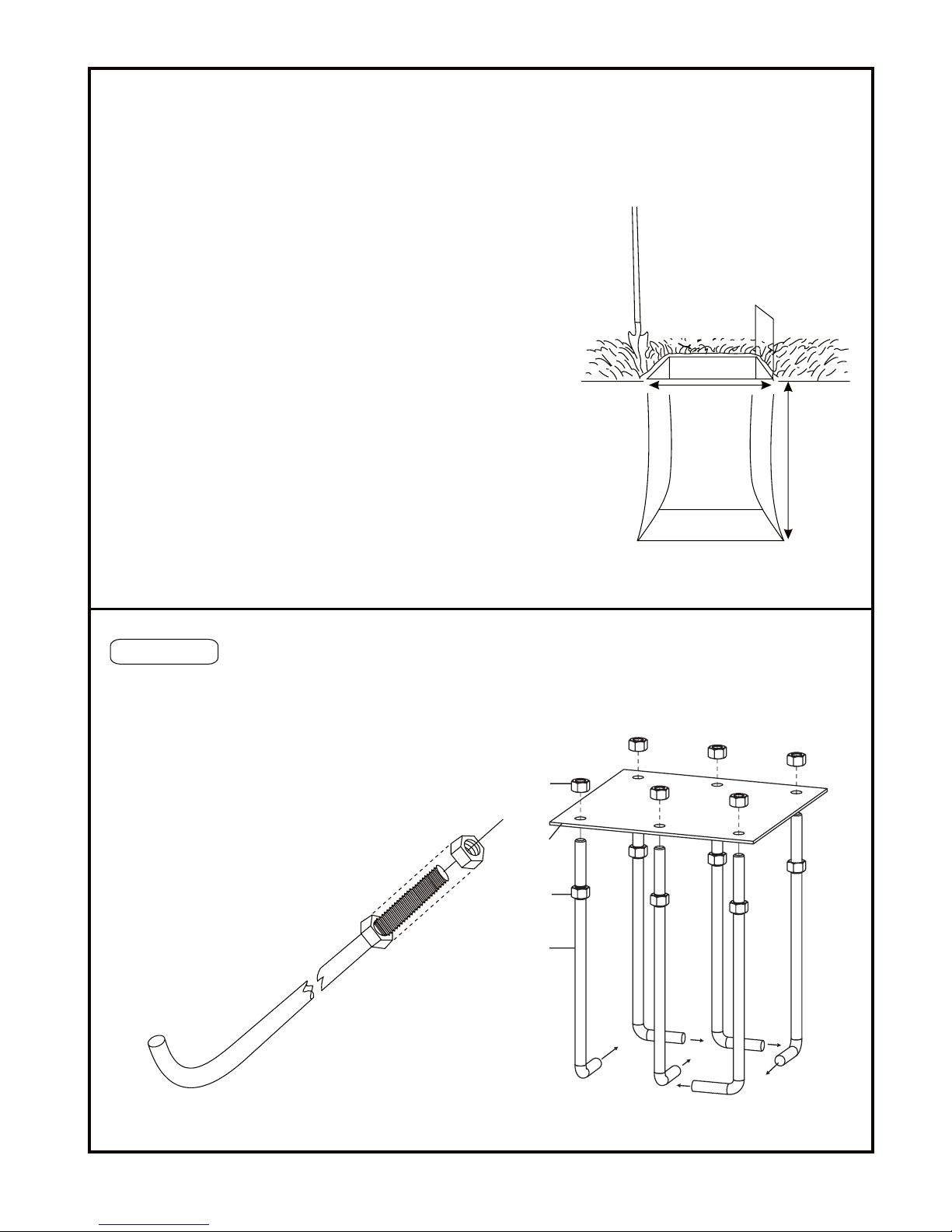

STEP C

STEP D

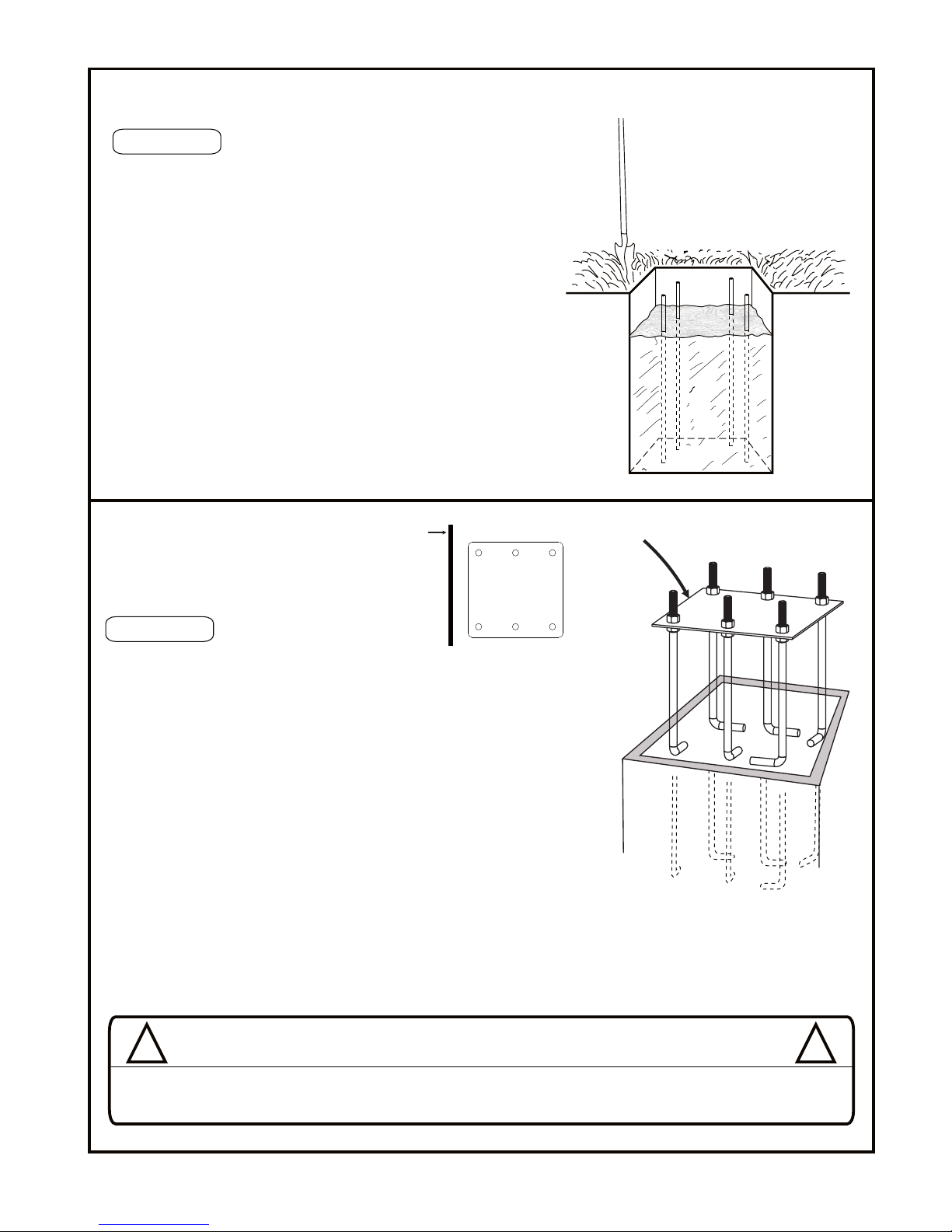

a. Mix the concrete according to the instructions on the bags. Note that

a thicker mix of concrete will dry stronger than a thin mix. Pour the

concrete into the hole, stopping approximately 18 inches from the top

of the hole.

b. Insert the four pieces of Anchor Rebar (U5) into the hole, pushing each

piece firmly to the bottom of the hole. The four pieces should be

arranged in a square approximately 8 inches wide so that each piece of

rebar will be positioned next to the J-Bolts when the J-Bolt Template

is placed in the cement.

c. Finish filling the hole to the top with concrete. The top of the concrete

should reach just above the level of the top of the form.

U5

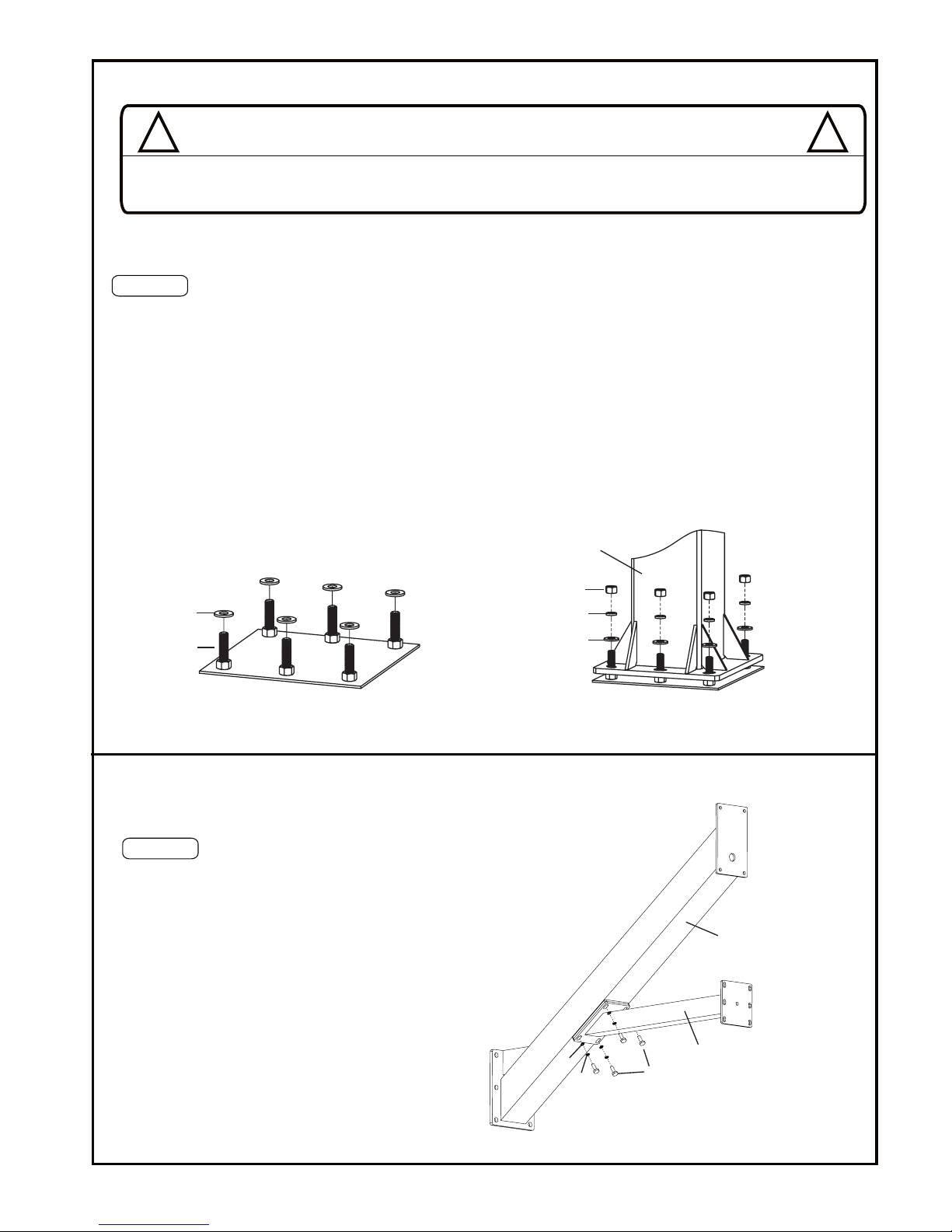

a. Position the J-Bolt Template (U1) over the hole as shown.

with the sides of the plate square with the sides of the hole.

b.Push the J-Bolts (U2) into the concrete until the J-Bolt Template is

resting flat against the surface of the concrete.

c. Grasp the tops of the J-Bolts and agitate the Template assembly back

and forth repeatedly to eliminate any air bubbles in the concrete. Lift the

Template slightly above the concrete when agitating . Make sure the

Template is resting on the concrete after agitating. Form the concrete

into a downward slope away from the Pole to allow water runoff.

d. Clean off any concrete that may be on the J-Bolt Template or the exposed

portions of the J-Bolts.

e. Using a carpenter’

s level, make sure the Template is square to and level

with the playing surface.

f. Allow the concrete to cure for a minimum of 5-7 days before installing

the rest of your basketball system. In cold , wet weather or humid

climates, allow additional time for the concrete to cure.

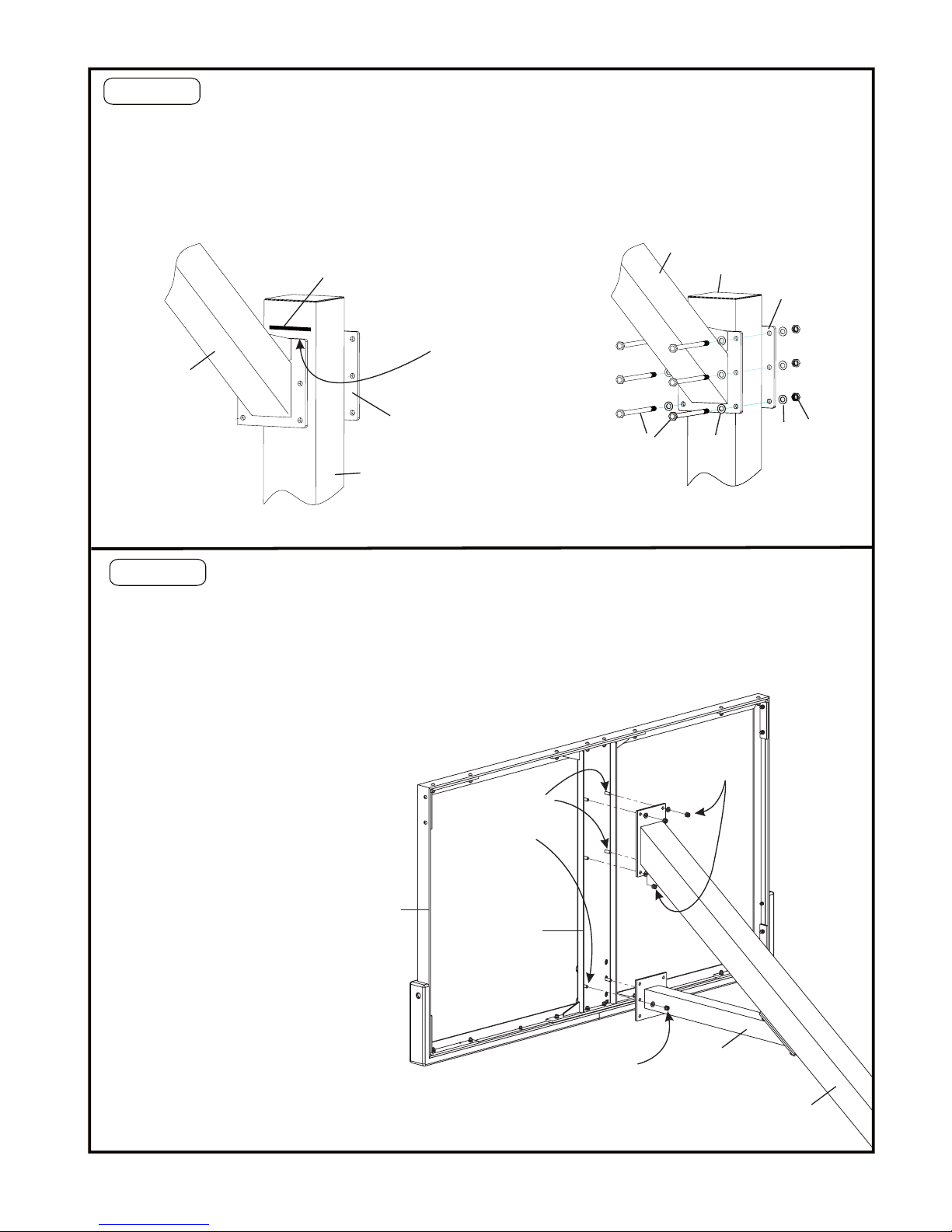

YOU ARE NOW FINISHED WITH THE INITIAL ASSEMBLY STEPS. DO NOT PRO-

CEED WITH THE ASSEMBLY UNTIL THE CONCRETE HAS FULLY CURED . CUR-

ING WILL TAKE A MINIMUM OF 72 HOURS. IN HUMID CLIMATES OR WET

WEATHER, ALLOW ADDITIONAL TIME FOR THE CONCRETE TO CURE.

!!

WARNING

NEVER USE THE SYSTEM WITHOUT FOLLOWING THE CEMENTING INSTRUCTIONS . FAILURE TO

FOLLOW ALL OF THESE INSTRUCTIONS AND WARNINGS COULD LEAD TO SERIOUS PERSONAL INJURY

OR PROPERTY DAMAGE AS LISTED ON PAGE ONE.

5

Playing surface

(Front side)

Anchor

template

Edge of

playing surface

This side faces

playing ground