3

INSPECTION FREQUENCY:

SRL-LEs shall be inspected by the authorized person or rescuer before each use.

Inspection shall be conducted by a competent person other than the user.

The competent person shall use Inspection Schedule and checking list for appropriate inspection intervals

and procedures.

Results of the Competent person inspection should be recorded in the " Inspection and Maintenance Log"

on the back pages of instruction.

APPLICATIONS:

Purpose:

This product is part of a personal fall arrest, restraint, work positioning, suspension, or rescue system.

A Personal Fall Arrest System (PFAS) is typically composed of an anchorage and a Full Body Harness (FBH),

with a connecting device, i.e., a Shock Absorbing Lanyard (SAL), or a Self-Retracting Device (SRL), attach to

the dorsal D-ring of the FBH.

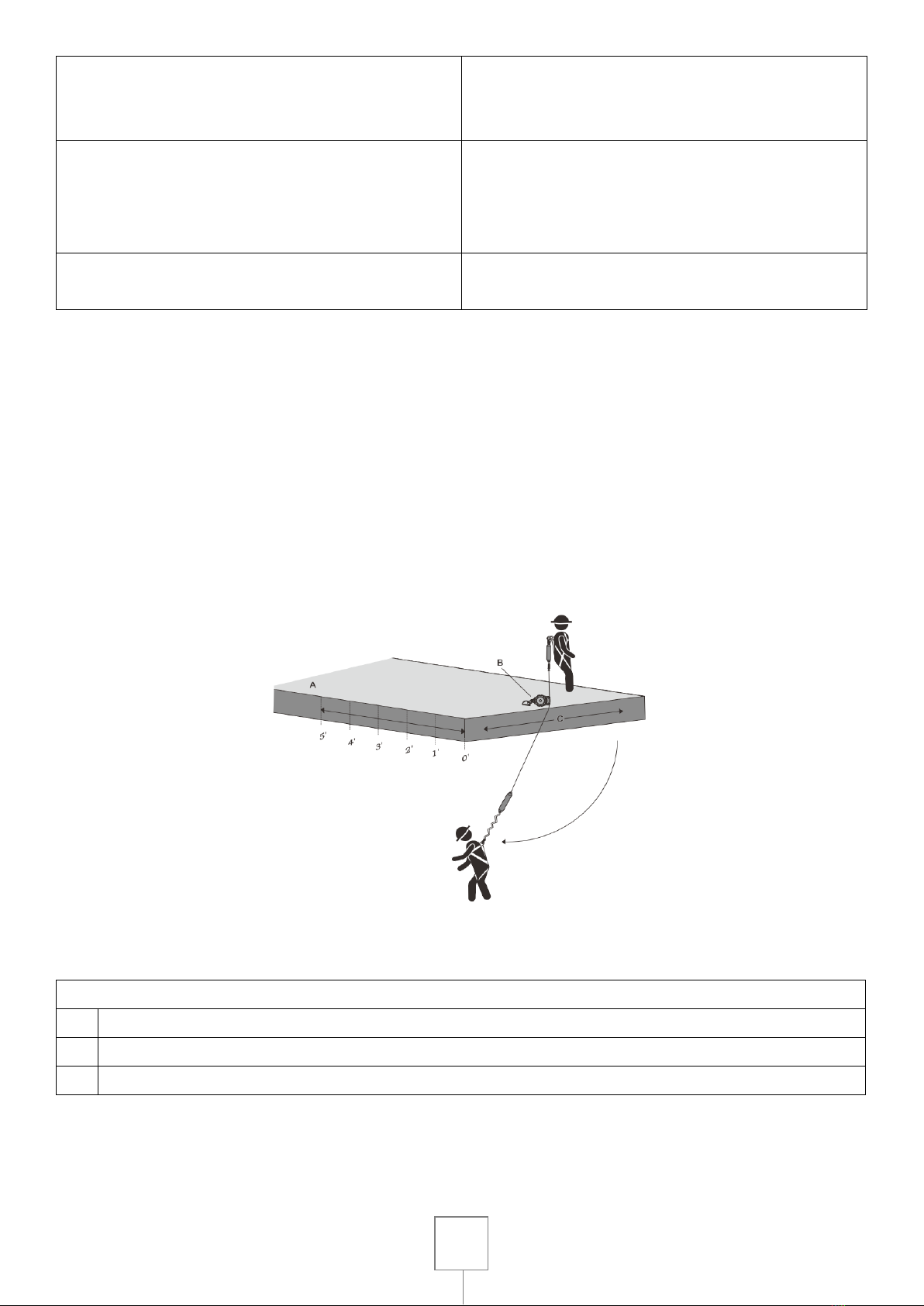

SRL-LEs are designed for use in applications where falls may occur, including falls over edges, such as

roofing, leading edge construction, etc.

SRL-LEs covered by this manual, SRL-LEs may be used in many situations where a combination of work

mobility and fall protection is required. (i.e. inspection work, general construction, maintenance work, oil

production, confined space work, etc.)

The 2408D-LE incorporate two SRL-LE units that can be used for application where 100% tie-off is required.

Standards:

SRL-LEs confirm to the national standard identified on the label. Refer to local, state, and federal

(OSHA)requirements governing occupational safety for additional information. The standard is ANSI

Z359.14 - Safety Requirement for Self-Retracting Device for Personal Fall Arrest and Rescue Systems.

Free Fall:

When anchorage overhead, SRL-LEs will limit the free fall distance to 2ft. (61cm) or less.

To avoid increased fall distances, anchor the SRL-LE directly above the work level.

Avoid working where your lifeline may cross or tangle with that of another worker.

Never clamp, knot, or prevent the lifeline from retracting or being taut.