Ironwood JT300 | User Manual 3

1.0 General Information

1.1 Thank You!

Thank you for your purchase of the Ironwood JT300 jointer. At Stiles

Machinery, our goal is to ensure that you are fully satised with

your purchase. This manual is provided so that you may properly

assemble, operate, and maintain your JT300. Should you need help,

our team of dedicated service personnel are available to answer

your questions and provide any resource recommendations you may

need.

Warranty and Support

All Ironwood machines are designed to meet the exacting standards

demanded by craftsmen like you. Ironwood machines include a

one (1) year parts warranty and two (2) years of free 24/7 technical

support beginning at date of shipment. Standard technical support

remains in effect for free for the lifetime of the machine thereafter.

Warranty service work is not covered by manufacturer’s warranty.

Stiles’ service team is available for an additional charge.

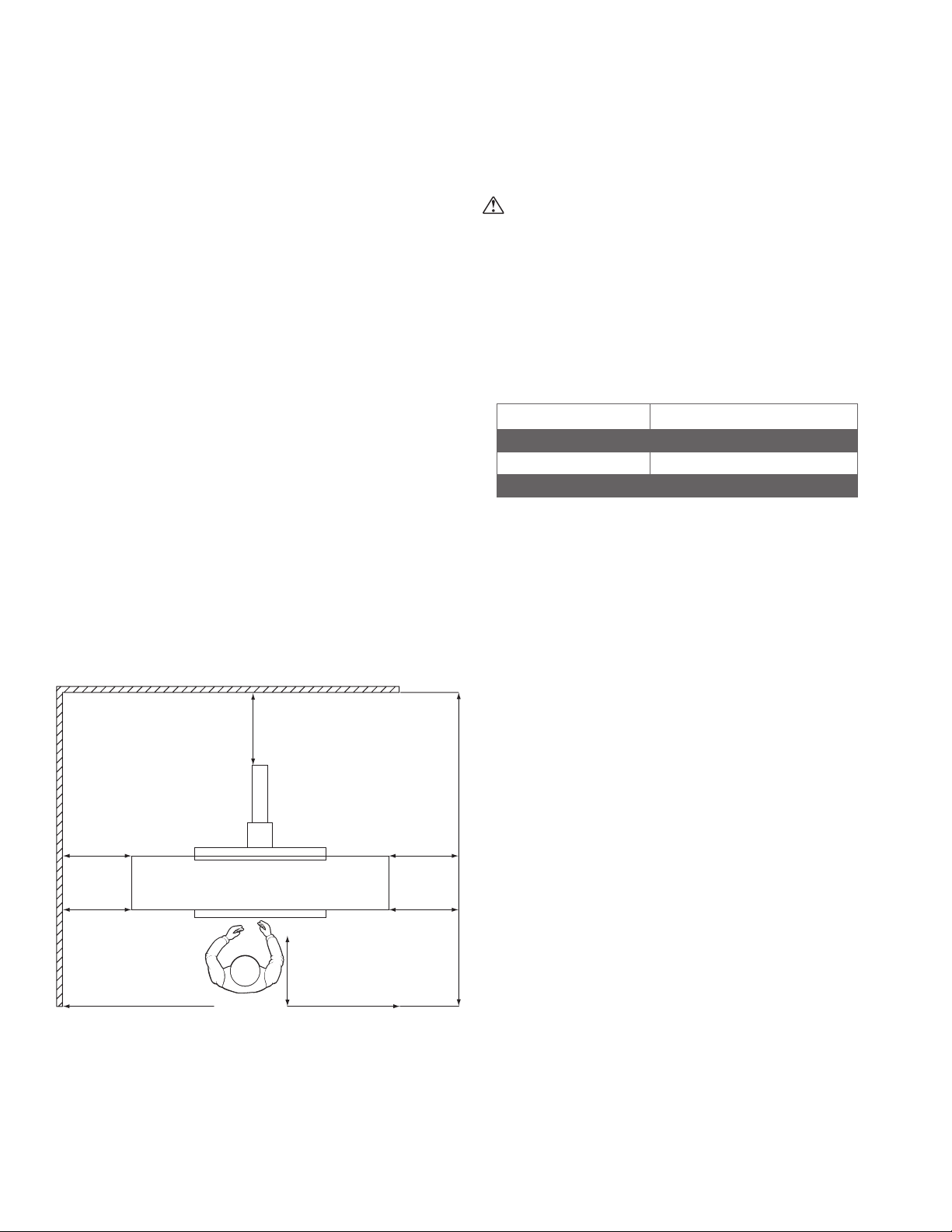

1.2 Before Contacting Stiles

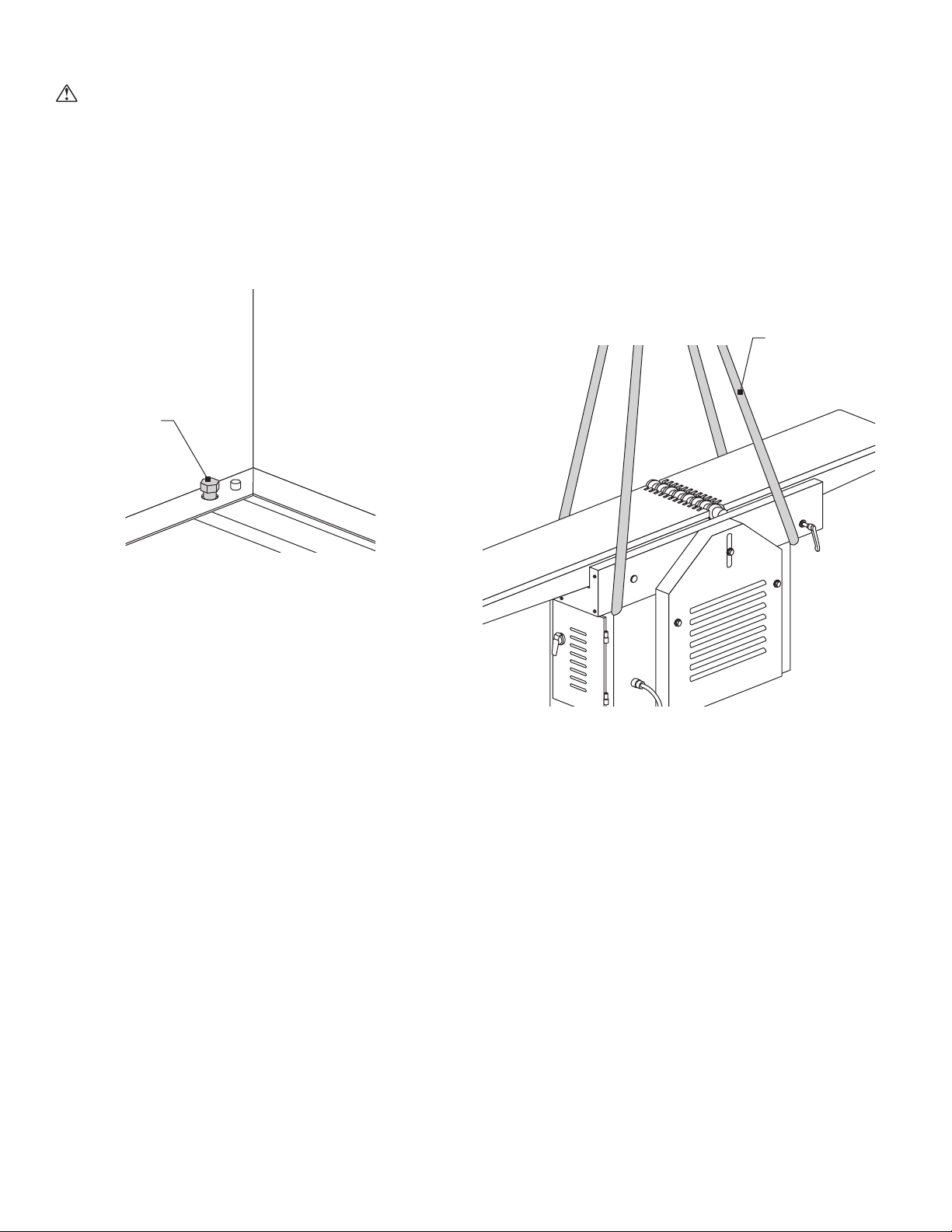

Please have your machine model and serial number available when

contacting Stiles Machinery with questions. The machine’s model

and serial number are listed on the metallic plate located on the

machine’s frame.

Information regarding the electrical system and pneumatic supply

are also listed on the metallic plate.

Machine information plate

Stiles Technical Support

616.698.6615

Stiles Parts

800.PARTS.80 (800.727.8780)

Website

www.stilesmachinery.com/ironwood/jt400

Machine Model ____________________________________________

Machine Serial Number _____________________________________

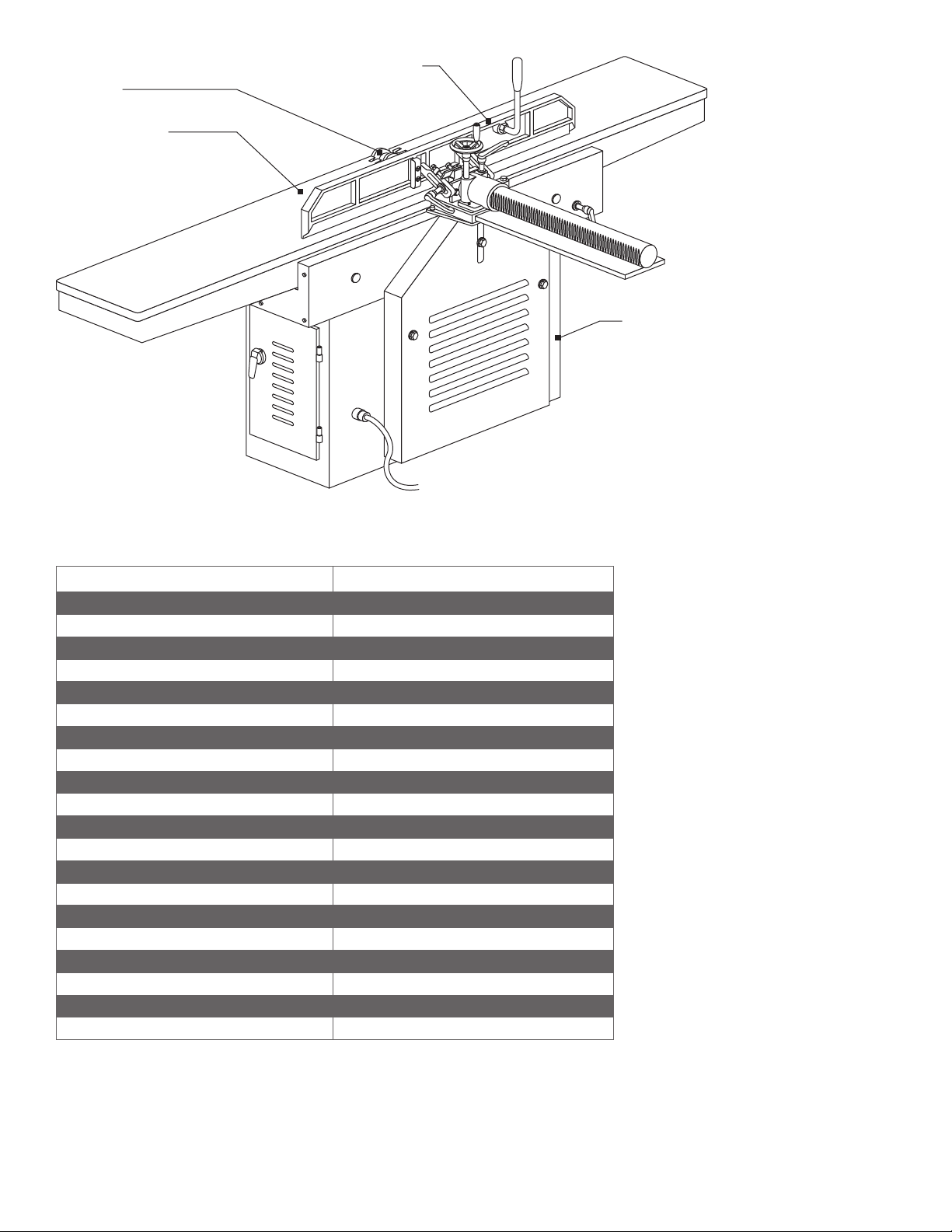

1.3 Features

• Solid construction featuring cast iron tables

• Generous 84" cutting length

• 12" cutting width with up to ¾" cutting depth

• Heavy duty steel machine base for vibration free jointing

operations

• Proven parallelogram table design

• Centralized control panel with power switch, emergency stop

switch, and power disconnect

• Quick set-up for the infeed and outfeed tables using vertical

adjustment levers

• Spiral cutterhead with carbide inserts for smooth and quiet

operation

• Heavy-duty 5-hp cutterhead motor

• Easily adjustable back fence with stops at 45, 90 and

135 degrees

1.4 Intended Use

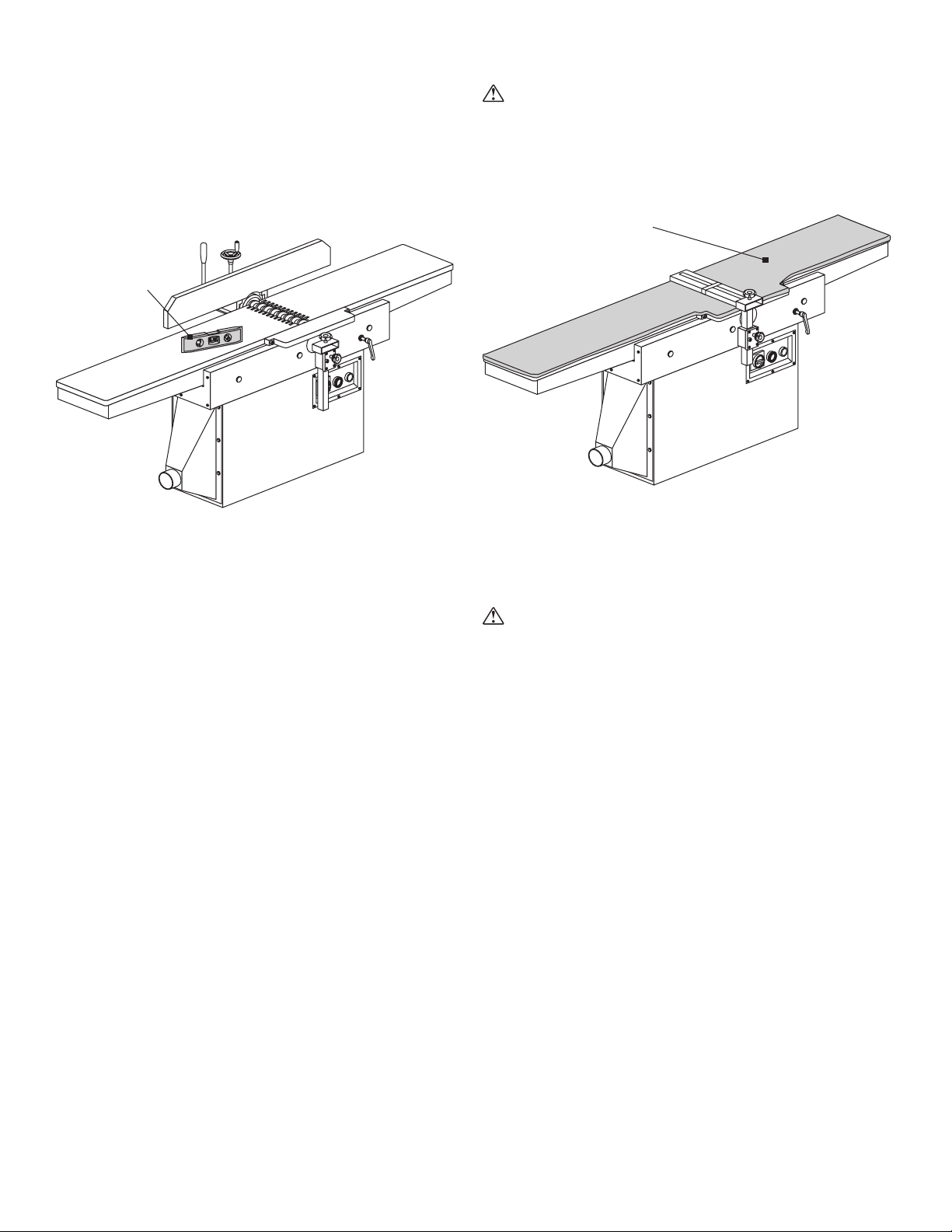

The JT300 jointer is used to atten and straighten rough lumber,

boards, and other wood products before nishing. Face jointing

removes bowing and twists in a board that is positioned at on the

machine table. Straight-lining or edge-jointing squares a board that

is positioned on its edge on the machine table.

The machine has a 12" (305mm) cutting width, enhanced

engineering designs, and superior build construction. It offers

intelligent standard features like an interchangeable fold-away bridge

guard, helical cutting system for quiet operation, and 84" (2,135mm)

cutting length.