10 / 48 FRITZMEIER Umwelttechnik GmbH & Co. KG V1.1

ISARIA PRO Compact®Safety

4Safety

4.1 Proper use/warranty

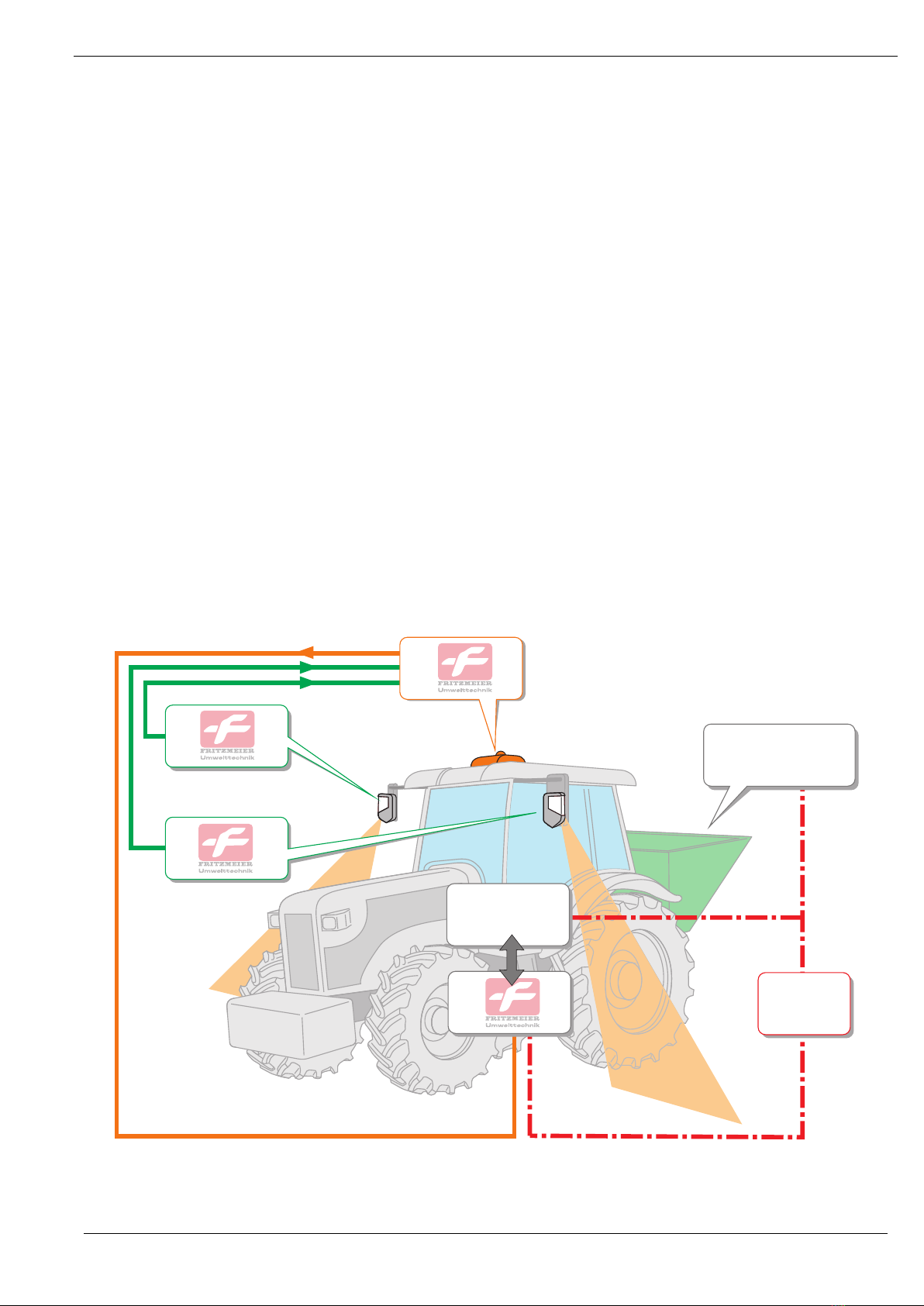

The ISARIA is intended to determine the development state of crops and to optimise crop

management.

Every other use is classified as improper.

Any conversions performed or add-ons fitted without explicit written approval of the manufacturer,

the use of spare parts that are not genuine and repairs performed by any persons or companies not

authorised by the manufacturer, as well as modifications (operating system, software* and

hardware) may render the warranty void.

* Updates to the operating system must be made available with the explicit approval of the

manufacturer. Mass storage devices that are to be connected to the terminal must be classified as

free from malware and malicious code using state-of-the-art technology.

4.2 Selecting personnel and required qualifications

Persons working with the ISARIA must be

-at least 18 years of age.

-adequately trained for the respective activities.

-aware of and comply with relevant technical regulations and safety guidelines.

The operator decides on the required qualifications for

-operating personnel

-maintenance personnel

-repair personnel

The operator must ensure that only commissioned personnel work with the ISARIA.

Personnel to be trained, taught, instructed or personnel currently undergoing general professional

training must be supervised by experienced persons at all times when working on the ISARIA!

All work on the ISARIA must be performed only by trained specialist personnel, and in compliance

with all valid accident prevention regulations (UVV).

4.3 Organisational safety

The operator must ensure that the operating and maintenance manual is always made available

immediately to persons performing assembly, operation and maintenance on the ISARIA.