4

1.0 Introduction

This Central Inverter System integrates the latest power electronics and microprocessor technology

which produces a pure sine wave power output intended for use in Emergency Lighting. The system is

very efficient on-line and typically has a standby power loss of only 2 percent of the systems total

capacity which means it is 98% efficient. This high efficiency and the ability to turn lighting loads on and

off using the optional switched load outputs make it ideal for energy saving and green initiatives. This

equipment was specifically designed for modern lighting loads and as such has very high inrush current

capability which are required for today’s LED drivers and electronic lighting loads. It is UL-924 compliant

for Self-Testing and Self Diagnostic and as such performs internal checks and tests and records them in

backup logs. The MMI (Man Machine Interface) which consists of a 5 button keypad and backlit LCD

display is very powerful and feature rich. Users can access all stored logs and diagnostic tools such as

meter functions, they can also change alarm functions and much more. The machine was designed on a

modular concept so virtually any voltage combination can be created using these modules including

single phase, split phase, and three phase.

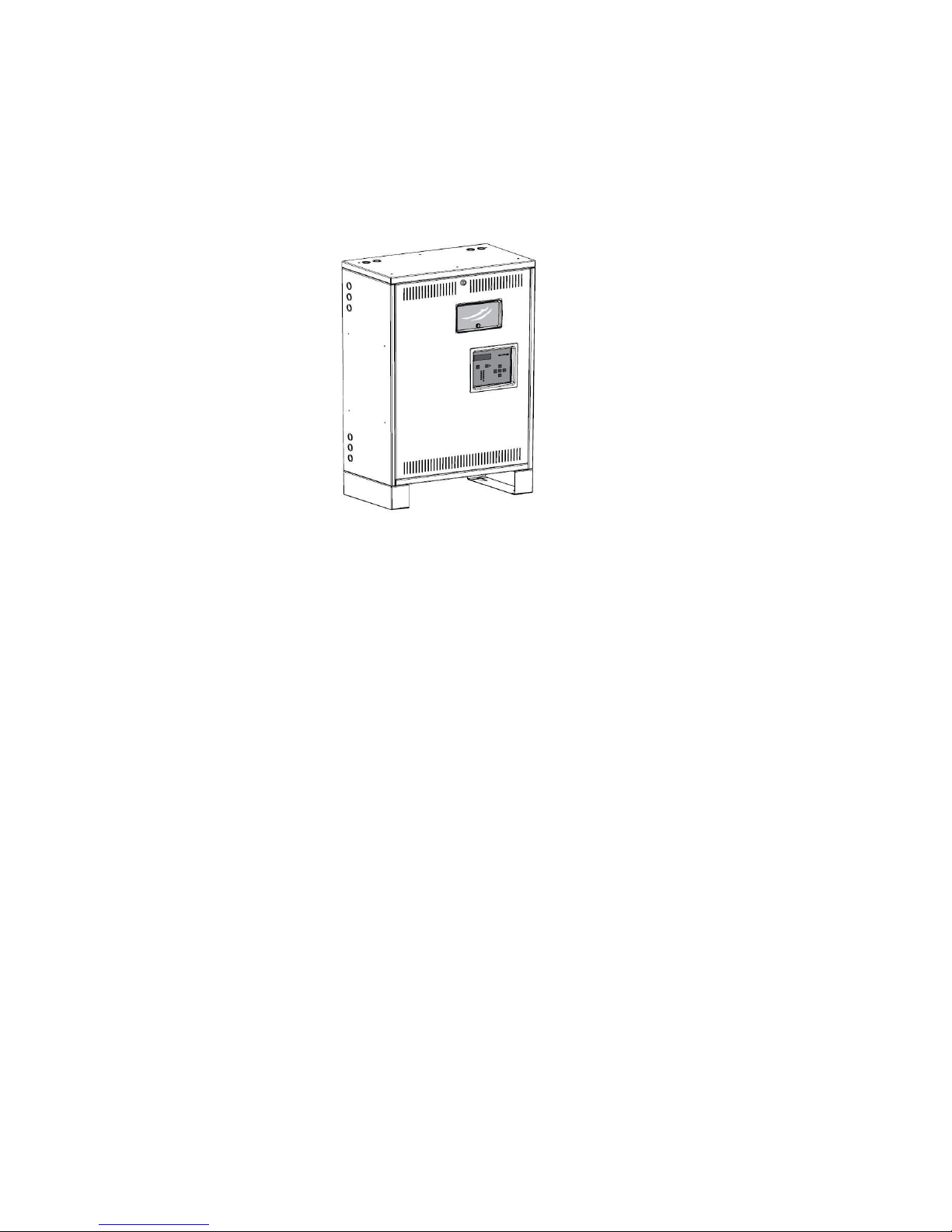

1.1 Mechanical Features

This product was designed having the electrical installer in mind. It can be easily recognized as the

simplest and fastest Central Inverter installation in the industry for its KVA size and capabilities.

Batteries are Front Terminal type which makes connecting up the batteries extremely fast. Simply slide

the batteries into the cabinet, connect up the jumpers and connect the inter-shelf (model dependent)

wiring and the battery install is finished. All battery connections come to the front –this means no

reaching to the back through a string of batteries to make connections! The AC connections are also

very easy to accomplish with the contractor landing the inputs and outputs to either Circuit Breakers or

Terminals, Neutral wires are connected to a common neutral buss bar and Ground wires are also all

connected to a common ground bar. Contractor wiring is very similar to connecting to an electrical panel

in that there are knockouts on both sides and tops of the cabinet for easy conduit connection and then

wires are then easily run into the cabinet and connected to ground bars, neutral bars and circuit

breakers.

The machine was designed for Seismic Zone 4, has Powder Painted 14 gauge Cold Rolled Steel

construction with no visible outside bolts or rivets. Internally, it has all galvanized or painted steel parts

for all the modules and shelves that resist corrosion and provide durability and high quality.

1.2 Electrical Features

This product line has one of the most flexible voltage configurations in the industry due to its modular

design concept. Each module can be configured as 120 or 277 or 120/240. The modules can be arranged

in parallel, series or Wye connected. This gives the capability of producing voltages of single phase (L-N

and L-L), split phase (L-N-L), and three phase. By utilizing a modular concept, it provides scalability, quick

delivery and in the event of issues, very fast MTTR (Mean Time to Repair).