PEGASUS

PLUS

1200

HANDBOOK

ISSUE 5 - 01/05

Page 2 of 50

CONTENTS

PAGE DESCRIPTION

3,4 EMC Information

5Health & Safety Instructions

6Guarantee

7 Cautionary Note

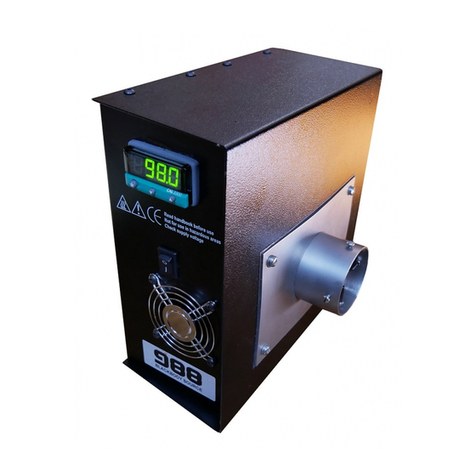

8Introduction

9,10 Unpacking & Initial Inspection

11,12 Specification

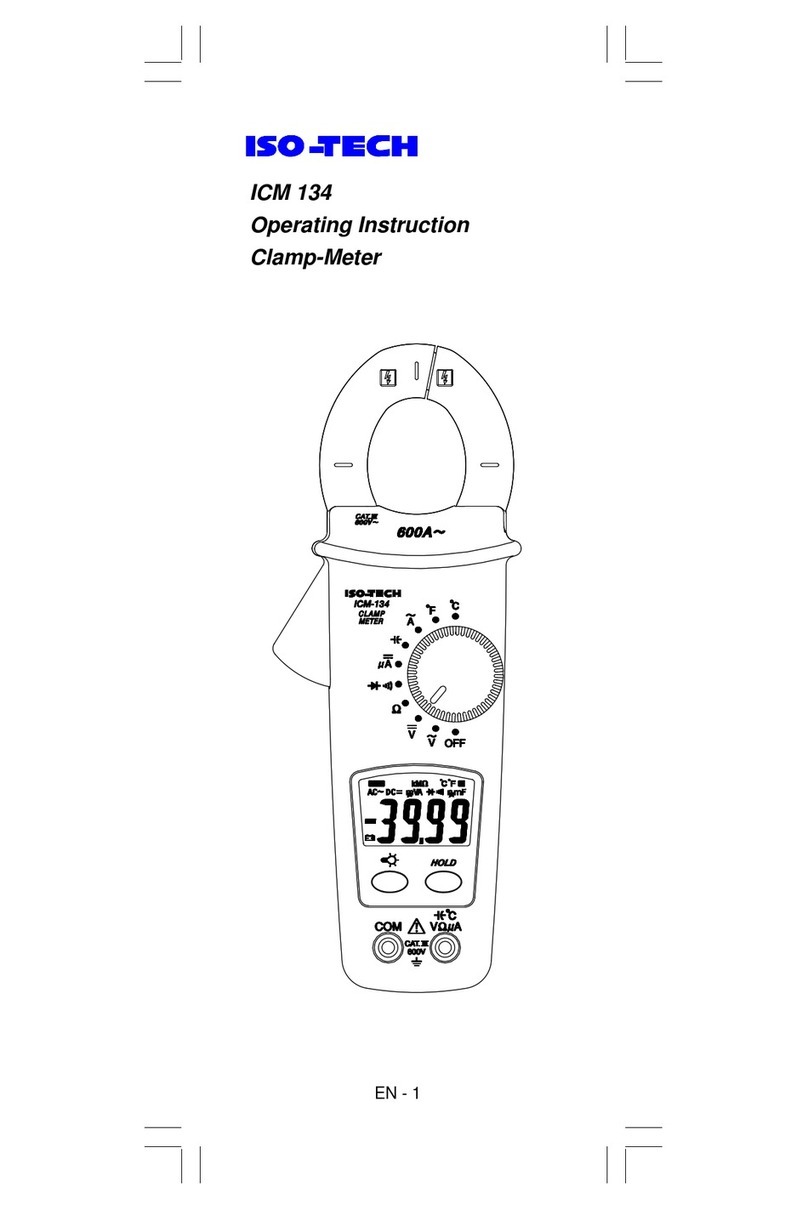

13,14 Assembling the Insert

15 Operating the Controller

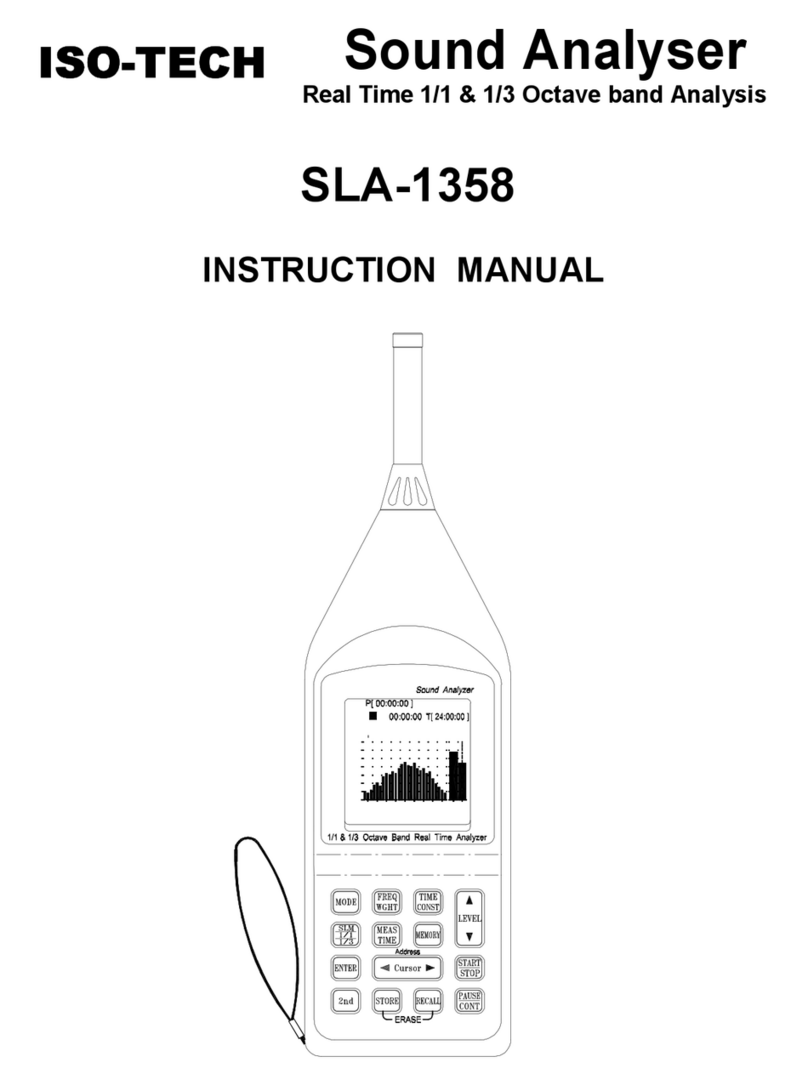

16,17,18,19 Operating the Indicator

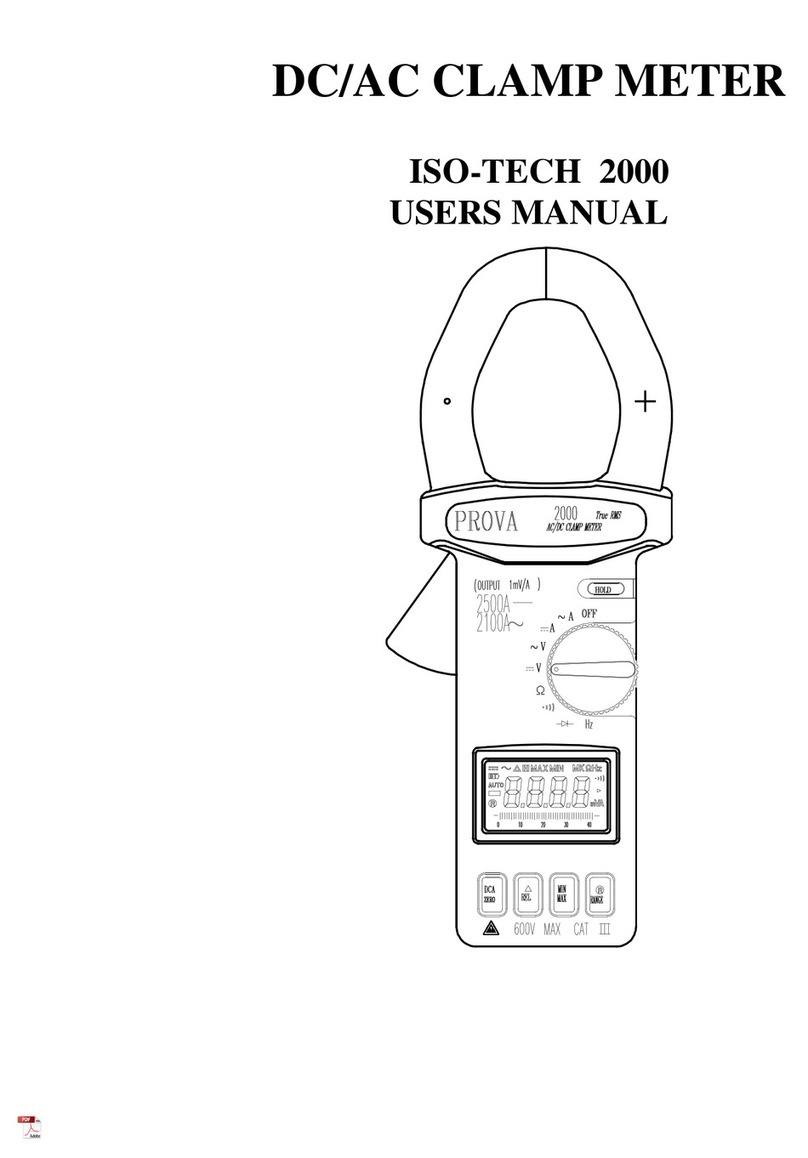

20,21 Connecting a Current Transmitter (up to 20mA)

Testing Thermostats

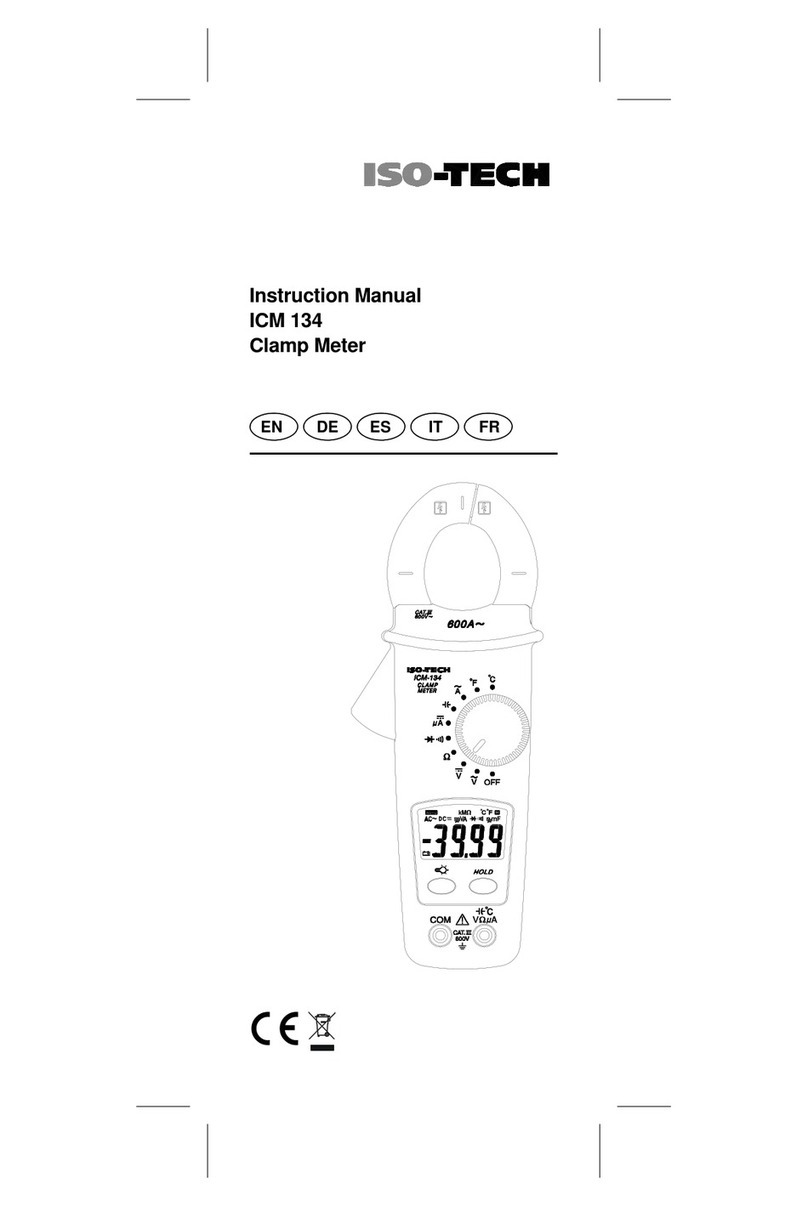

22 Using the PC Interface

23,24 Using Cal Notepad

25 Diagnostics (Error Messages)

26,27 Pegasus

Plus

1200S, 1200B - Initial Testing

28 Pegasus

Plus

1200S, 1200B - Maintenance

29 Operating Procedures

30 Pegasus

Plus

1200B, 1200S - Checking Using the Temperature Indicated on

the Controller

31 Pegasus

Plus

1200B, 1200S - Calibration Using a Standard Thermometer

with External Indication

32 Pegasus

Plus

1200 S - Calibration Using a Standard Thermometer and the

Internal Indicator

33 Pegasus

Plus

1200S - Calibration Usi n g the Internal Indicator to Read a

Standard and Unknown Thermometers

34 Pegasus

Plus

1200S - Using the Indicator to Measure TemperaturesRemote

from the Furnace

35 Figure 1

36 Figure 2

37 Appendix 1 - Trouble Shooting

38 Appendix 2 - Accessories

39,40 Appendix 3 - Indicator Configuration

A - L Metal Block Tutorial