3

Contents

1 UNPACKING AND INITIAL INSPECTION.........................................................................................5

2 BEFORE YOU USE THE EQUIPMENT ................................................................................................ 6

3 SUMMARY OF SYMBOLS ....................................................................................................................7

4 ELECTRICITY SUPPLY....................................................................................................................... 8

5 THE UNIT MUST BE EARTHED ................................................................................................. 9

6 EMC INFORMATION .................................................................................................................10

7 CAUTIONARY NOTE................................................................................................................. 11

8 SAFETY WARNINGS ................................................................................................................ 12

8.1 ENVIRONMENTAL CONDITIONS........................................................................................................................12

8.2 DO NOT MODIFY OR DISASSEMBLE.................................................................................................................12

8.3 BEWARE OF ELECTRICAL CONSIDERATIONS......................................................................................................12

8.4 BE CAREFUL WHERE IT IS USED.....................................................................................................................12

8.5 BE CAREFUL WITH EXTREMES OF TEMPERATURE..............................................................................................12

8.6 BE CAREFUL WITH INSERTS ...........................................................................................................................12

9 CONSIDER THE ENVIRONMENT ..................................................................................................... 13

10 INTRODUCTION .............................................................................................................................14

10.1 COMPARISON CALIBRATION..........................................................................................................................14

10.2 BASIC OPERATION.......................................................................................................................................14

10.3 SITE OR SELF-CONTAINED CALIBRATORS.......................................................................................................14

10.4 EXTERNAL STANDARDS +BASIC ................................................................................................................... 15

10.5 ADVANCED CALIBRATORS.......................................................................................................................... 15

11 MODE OF OPERATION ...................................................................................................................16

11.1 METAL BLOCK BATH ....................................................................................................................................16

11.2 BLACKBODY SOURCE....................................................................................................................................16

11.3 SURFACE SENSOR CALIBRATION....................................................................................................................16

11.4 STIRRED LIQUID BATH................................................................................................................................. 17

11.5 ITS-90 FIXED POINT CALIBRATION .............................................................................................................. 17

11.6 ISOTECH BASIC DRY BLOCK INTERFACE .........................................................................................................18

11.7 ISOTECH SITE DRY BLOCK INTERFACE ...........................................................................................................19

12 SPECIFICATION ............................................................................................................................. 20

13 BEST PERFORMANCE GRAPHS ..................................................................................................... 21

13.1 HEAT UP /COOL DOWN ..............................................................................................................................21

13.2 SIGMA UNCERTAINTIES................................................................................................................................21

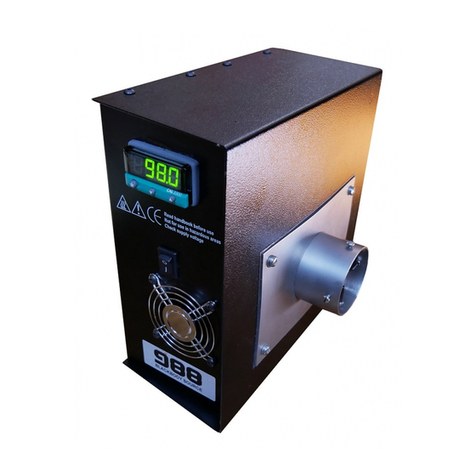

14 OPERATING THE MODEL ............................................................................................................... 22

14.1 FRONT PANEL LAYOUT .................................................................................................................................22

14.1.1 The Temperature Controller

...........................................................................................................22

14.1.2 Altering the Setpoint

.......................................................................................................................22

14.2 CONTROLLER FEATURES...............................................................................................................................22

14.2.1 Setpoint Ramp Rate

........................................................................................................................22

14.2.2 Instrument Address

.........................................................................................................................23

14.3 MONITORING THE CONTROLLER STATUS .......................................................................................................23