Page 2 of 29

Fast Cal Series Iss.07 –08/13

CONTENTS

EMC INFORMATION .................................................................................................................4

ELECTRICAL SAFETY ........................................................................................................................4

Environmental Ratings .................................................................................................................................................................... 4

HEALTH AND SAFETY INSTRUCTIONS ...........................................................................................5

‘DO’S AND DON’TS’ ........................................................................................................................6

GUARANTEE ....................................................................................................................................7

CAUTIONARY NOTE .......................................................................................................................8

UNPACKING AND INITIAL INSPECTION .........................................................................................9

ELECTRICITY SUPPLY.......................................................................................................................9

INTRODUCTION ...........................................................................................................................10

COMPARISON CALIBRATION ...................................................................................................................................................... 10

Basic ............................................................................................................................................................................................. 10

Site or Self-contained Calibrators................................................................................................................................................. 10

External Standards + Basic .......................................................................................................................................................... 10

MODE OF OPERATION ..................................................................................................................11

FAST-CAL HTM 2010...................................................................................................................................................................... 11

FAST-CAL......................................................................................................................................................................................... 11

How to measure the true temperature inside the block.............................................................................................................. 11

How to measure the true temperature inside the block.............................................................................................................. 11

The Controller ............................................................................................................................................................................. 11

The Reference Thermometer ...................................................................................................................................................... 12

The Industrial Thermometer........................................................................................................................................................ 12

SPECIFICATIONS (HTM 2010 & LOW MODELS) .............................................................................13

SPECIFICATIONS (MEDIUM & HIGH MODELS)...............................................................................14

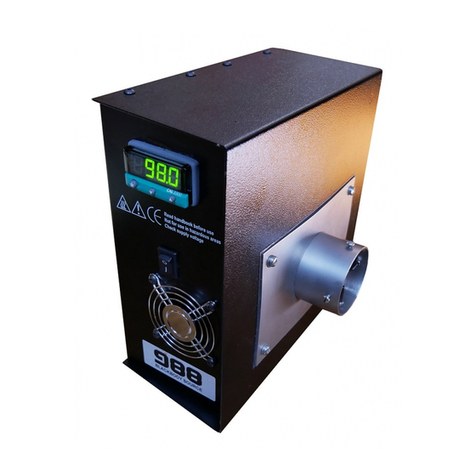

OPERATING THE FAST-CAL...........................................................................................................15

FRONT PANEL LAYOUT ............................................................................................................................................................... 15

The Temperature Controller ....................................................................................................................................................... 15

Altering the Setpoint .................................................................................................................................................................... 15

ADVANCED CONTROLLER FEATURES ...................................................................................................................................... 15

Setpoint Ramp Rate...................................................................................................................................................................... 15

Instrument Address ...................................................................................................................................................................... 16

MONITORING THE CONTROLLER STATUS .............................................................................................................................. 16

Units ............................................................................................................................................................................................. 16

THE TEMPERATURE INDICATOR (SITE (S) MODELS ONLY) ................................................................................................... 16