8

Conguration

4.3.2 pH calibration

4.3.3 Flow rate calibration

ENT

ENT

ENT

pH

CONTROL

ALARM

REGISTER

SP 07.00

PH CAL.

Point 1 07.00

Point 2 04.00

Reading 07.23

PH CAL.

Point 1 07.00

Point 2 04.00

Reading 07.23

If necessary for pH calibration point 1, modify the buer value using the up/down arrows. Insert the sensor

into the point 1 buer, wait until the sensor reading is stable and conrm with ENTER.

Repeat the operation with the point 2 buer. Before putting the sensor in the point 2 buer, clean the

sensor with distilled water and dry it well (with tissue paper) to avoid contamination of the buer. If at any

time during the calibration process you are not sure of the calibration, you can exit without conrming by

pressing ESCAPE.

CAL

m3h 0.20 %

SP

CAL

CONTROL

ALARM

ALARM DETECTOR

REGISTER

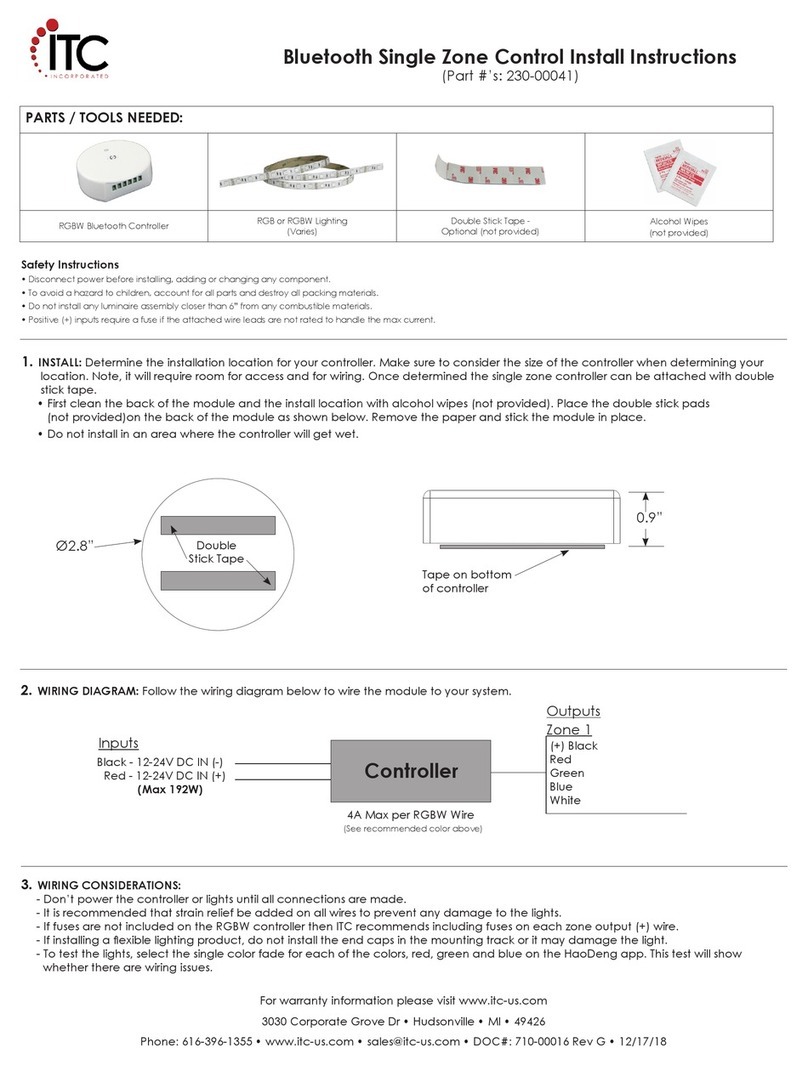

Q CAL.

Type: Low Freq

K: 5.00 l/p

Time Q=0: 015 s

Select the type of ow meter:

- Low Freq:

Low frequency ow meter. Flow meters with pulse frequencies of between a minimum of 1 pulse every

200 seconds and a maximum of 30 pulses per second (30 Hz).

- K (l/p):

This type of ow meter requires entry of the conguration value the manufacturer indicates in litres/pulse.

- Time Q=0:

In these ow meters, which calculate the ow rate from the time between two consecutive pulses, a wait

time from which the ow rate is considered to be zero needs to be dened.

- High Freq:

High frequency ow meter for Hall eect or electromagnetic insertion ow meters with a maximum of

300 Hz (300 pulses per second).

- K-factor (p/l):

This type of ow meter requires entry of the K-factor (pulses/litre), corresponding to the diameter where it

is installed. This value is supplied by the manufacturer.