TM542-2500, TM542-3200 & TM542-4200

PETROL PRESSURE WASHER OPERATOR’S MANUAL

SAFETY

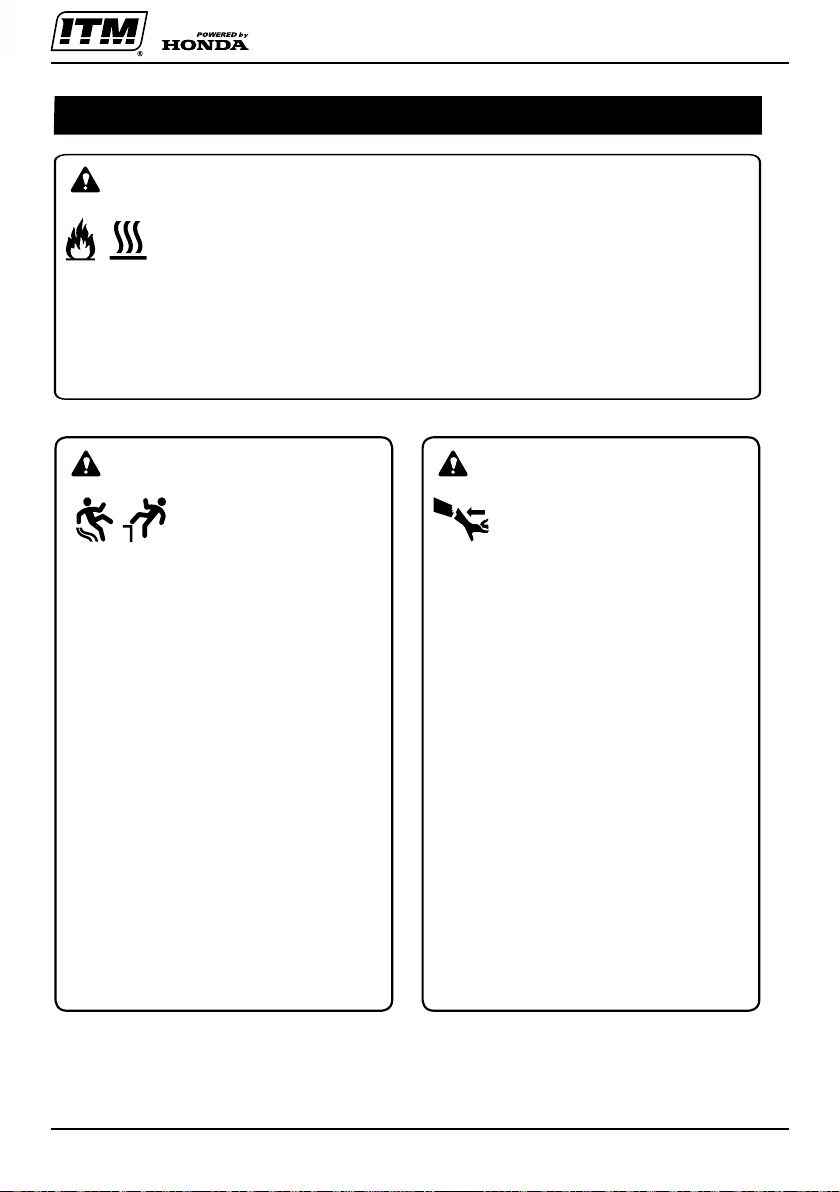

WARNING: Fluid Injection

The high-pressure water that

this equipment produces could

cut through skin and its underlying

tissues, resulting in serious injury and

possible amputation.

• Spray gun traps high water pressure,

even when engine is stopped and

water is disconnected, which could

result in serious injury.

•

immediately. DO NOT treat as a

simple cut.

• DO NOT allow CHILDREN to operate

pressure washer.

• NEVER repair high pressure hose.

Replace it.

• NEVER repair leaking connections

with sealant of any kind. Replace

o-ring or seal.

• NEVER connect high pressure hose

to nozzle extension.

• Keep high pressure hose connected

to pump and spray gun while system

is pressurized.

• ALWAYS point spray gun in safe

direction, disengage trigger lock and

squeeze spray gun trigger to release

high pressure, every time you stop

engine.

• NEVER aim spray gun at people,

animals, or plants.

• DO NOT secure spray gun in open

position.

• DO NOT leave spray gun unattended

while machine is running.

• NEVER use a spray gun which does

not have a trigger lock or trigger guard

in place and in working order.

• Always be certain spray gun, nozzles

and accessories are correctly

attached.

WARNING: Moving parts hazard

Starter and other rotating parts

could entangle hands, hair,

clothing or accessories, resulting in

serious injury.

• NEVER operate pressure washer

without protective housing or covers.

• DO NOT wear loose clothing, jewelry

or anything that could be caught in the

starter or other rotating parts.

• Tie up long hair and remove jewelry.

WARNING: Projectile hazard

Risk of eye or bodily injury.

Spray could splash back or

propel objects resulting in serious injury.

• Always wear safety goggles marked to

comply with ANSI Z87.1 when using or

in vicinity of this equipment.

• Always wear protective clothing such

as a long-sleeved shirt, long pants and

close-toed shoes.

• NEVER operate pressure washer

when barefoot or wearing sandals.

CAUTION: Engine Speed

Excessively high operating speeds could

result in minor injury. Excessively low

speeds impose a heavy load on engine.

• DO NOT tamper with governor spring,

links or other parts to increase engine

speed. Pressure washer supplies

running at governed speed.

• DO NOT modify pressure washer in

any way.

Risk Of Injection Or Injury

DO NOT direct discharge stream at persons.

9

www.itmtools.com.au