Page 2 of 8 GC31-IOM Rev. B 07/19

SUPPLY PRESSURE (20 to 100 psi / 138 to 690 kPa)

A regulated and filtered air supply should be used. A Conoflow

model FR95 Airpak Filter Regulator or equal is recommended.

ZERO ADJUSTMENT

Zero adjustment can be made by turning the zero adjust

coupling, located on top of the headplate assembly (2), clockwise

or counterclockwise. Connect supply and instrument air to the

positioner. Set the instrument signal to the 0% value (e.g. 3 psi

(21 kPa) for a 3-15 psi (21-143 kPa) range). Turn the zero adjust

coupling to bring the actuator slightly off the fully retracted

position. The starting point may then be checked by reducing the

instrument signal below the 0% value and then slowly increasing

it. As the 0% input signal is reached, extension of the actuator

stem plus an audible increase in the air flow through the

positioner should be observed.

Next, increase the instrument signal to the 100% value (e.g. 15

psi for a 3-15 psi (103 kPa for a 21-103 kPa range). Verify that

the actuator stem moves to the fully extended position.

Set the instrument signal to the 50% value. Using a suitable

measuring device, such as a scale, verify the actuator stem has

extended to 50% of full stroke.

SPAN

Positioner span determines the control range. A positioner with a

3-15 psi (21 to 103 kPa) range has a 12 psi (83 kPa) span and is

set with a 3 psi (21 kPa) start point (retracted position).

Positioner span has been factory calibrated as specified.

Instrument signals of 3-9, 3-15 and 6-30 psi (21-62, 21-103, and

41-207 kPa) are available. For field changes, refer to page 4 of

this manual and Range Spring Manual C-8053.

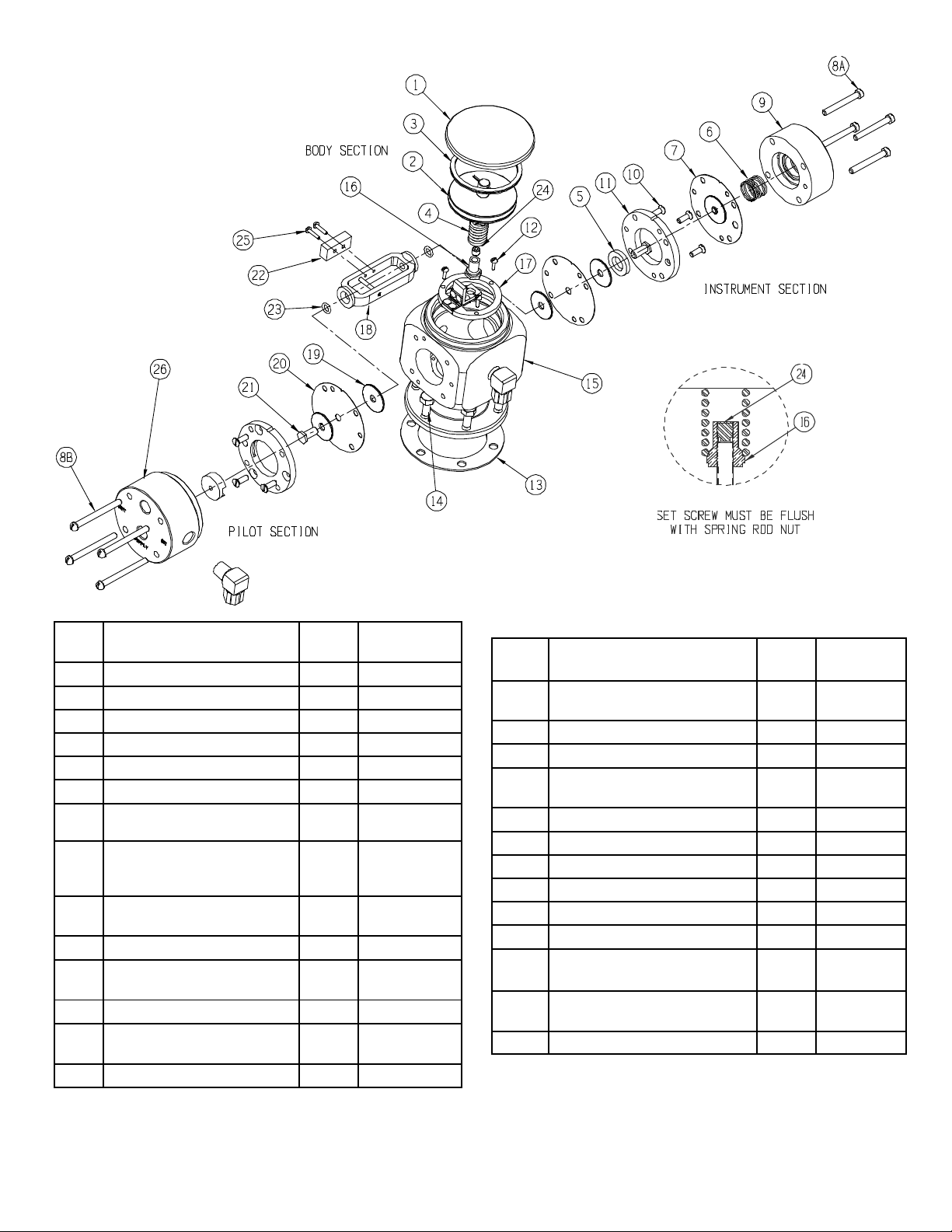

REMOVING POSITIONER FROM ACTUATOR

WARNING: Shut off supply and instrument

air and assure all pressure is bled before

performing any maintenance.

Piston (or diaphragm) should be in the fully retracted position.

Disconnect tubing and verify all air is bled from the actuator.

Remove cap (1) and Spirolox ring (3) from positioner so the head

plate assembly (2) can be lifted out. Loosen setscrew (24) using

a 1/8” hex key wrench, and remove spring rod nut (16). Remove

the six cap screws (14) and lift positioner from the actuator.

INSTALLING POSITIONER ON ACTUATOR

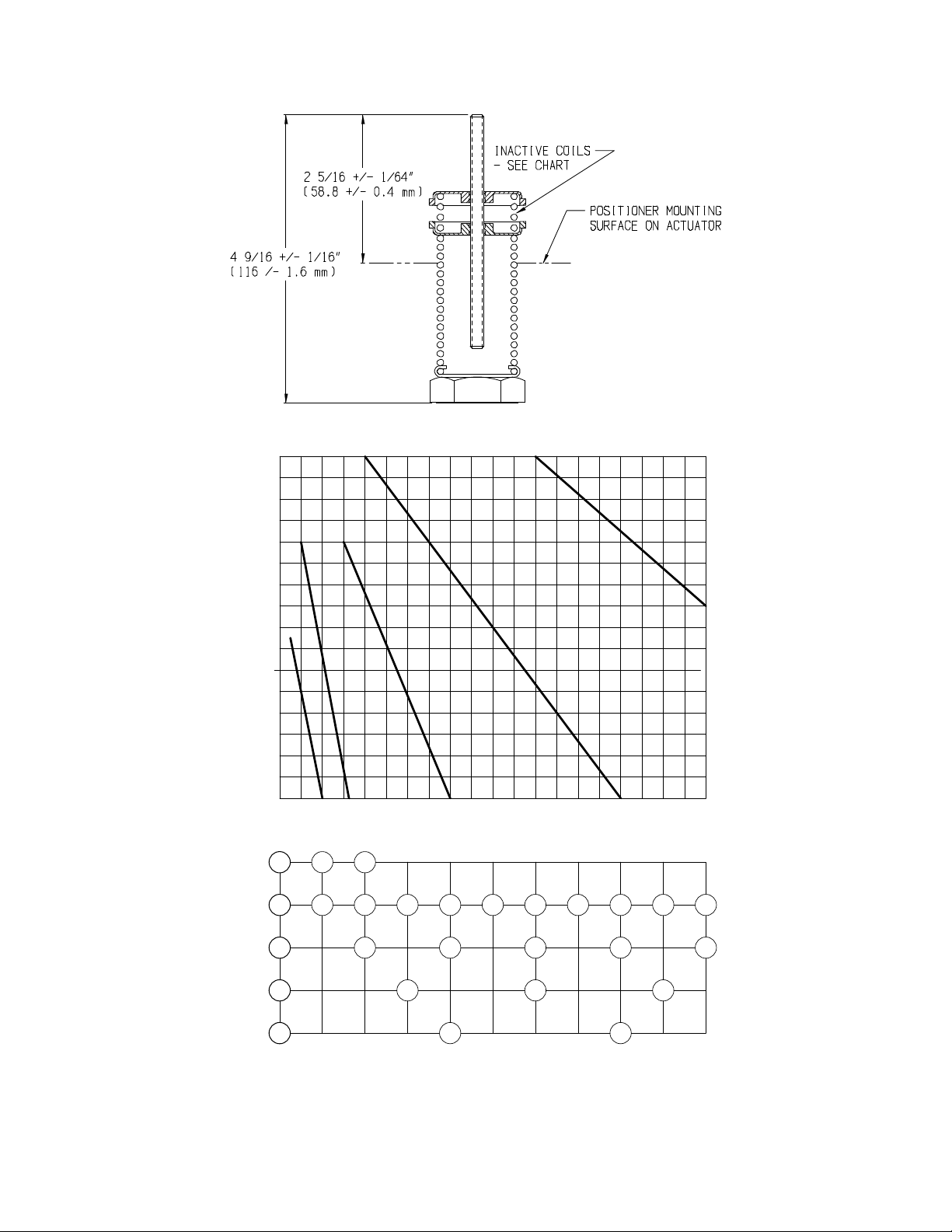

The Model GC31 positioner is designed for actuators having a 2

¼” dimension between the lower face of the range spring nut

(8D) and the positioner mounting flange with the actuator stem in

a retracted position. See dimensions on Page 5.

The range spring (8C) is adjusted and set at the factory for the

proper range and spring rod (8A) extension, as shown on page 6.

With the actuator stem in the fully retracted position and the

spring rod nut (16) removed from the spring rod (8A), thread the

spring nut assembly (8D) onto the actuator stem. Hold the range

spring assembly in a vertical position without applying any

tension to the range spring (8C). Measure the distance between

the positioner mounting surface on the actuator (without gasket)

and the top of the spring rod (8A). This distance must be 2-5/16”

+/- 1/64” (58.75 +/- 0.41 mm) for proper operation of the

positioner (see page 4). If adjustment is necessary, grasp the

lower spring clip (8B) and range spring (8C) while retightening

the upper clip securely. Measure the 2-5/16” (58.75) dimension

again to make sure it is correct. Be sure the actuator stem is fully

retracted when making this measurement.

Remove the cap (1) from the positioner and, using a small

screwdriver, remove the Spirolox ring (3). Pull out the positioner

headplate assembly (2) and set it aside. The zero spring (4)

should also be attached to the headplate assembly. If not,

remove it also. Place the gasket (13) and the positioner on the

actuator, guiding the spring rod (8A) through the hole in the bell

crank (17). Install the six hex head cap screws (14) that secure

the positioner to the actuator.

Adjust the set screw (24) in the spring rod nut (16) such that the

head of the screw is flush with the top of the nut. Install this

assembly onto the spring rod (8A) finger tight. Hold the spring

rod nut (16) with a wrench to prevent rotation, and tighten the set

screw (24) securely. It is important to make sure that the spring

rod nut (16) does not turn while tightening the set screw in order

to maintain calibration of the range spring assembly.

Insert the zero spring (4) onto the headplate and install the

headplate assembly (2). Make sure the zero spring (4) is

properly centered on the spring rod nut (16) when inserting this

assembly. Replace the Spirolox ring (3). Connect the

necessary piping. Proceed with the zero adjustment procedure

previously outlined. When complete, replace the cap (1).

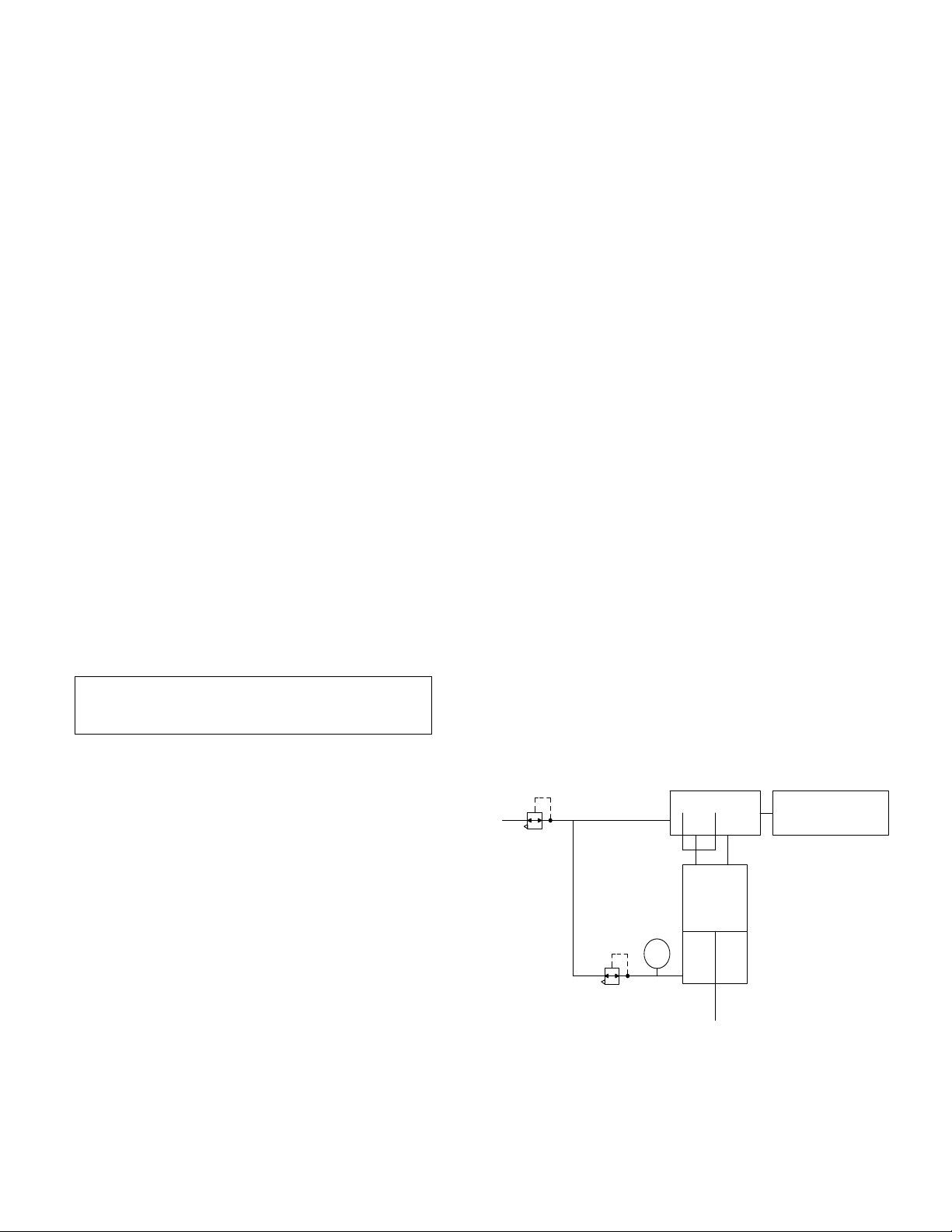

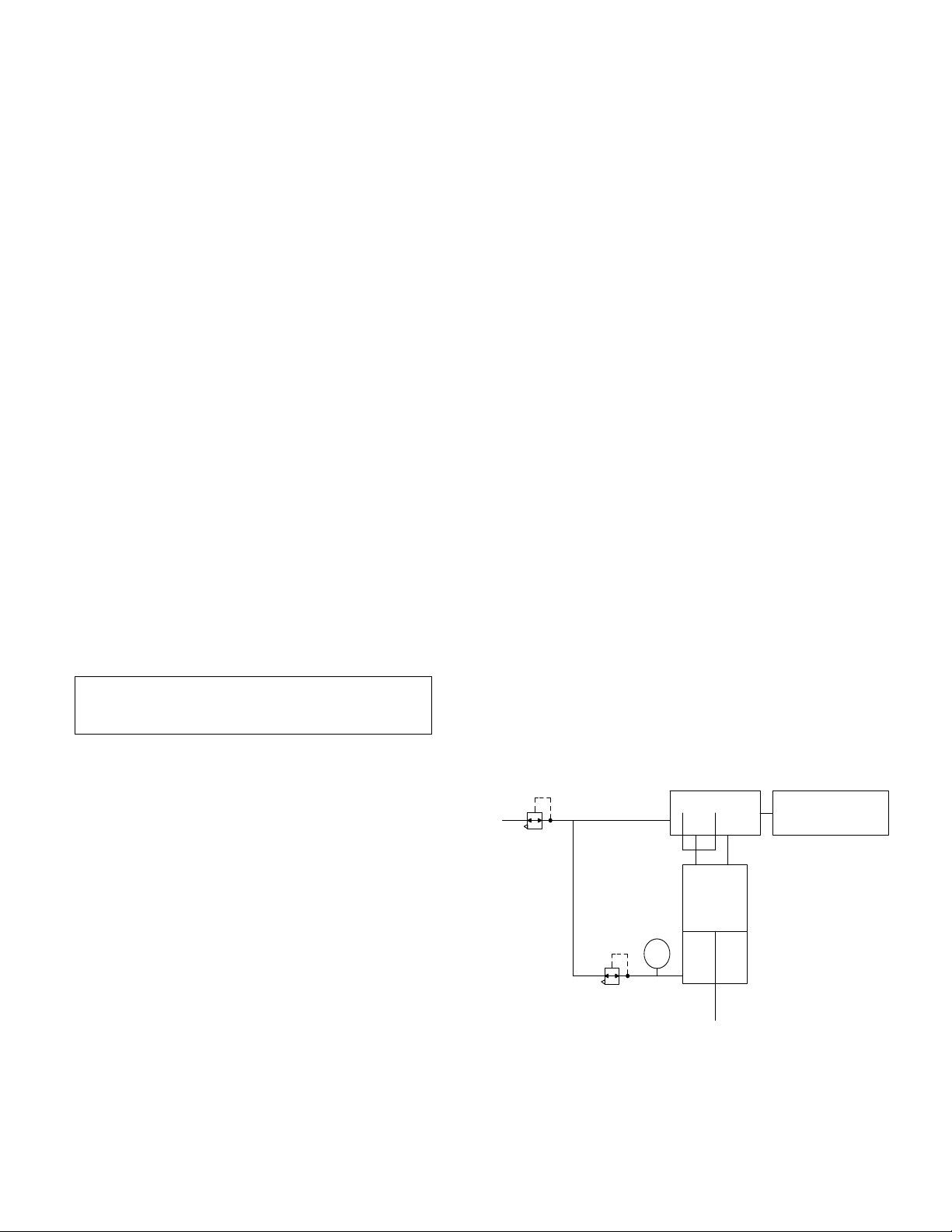

SYSTEM CONFIGURATIONS

The operation of the Commandaire GC31 positioner with an

actuator may be configured differently, depending on the needs

of the system. The following schematics illustrate several

common configurations for the model GC31 with a piston

actuator.

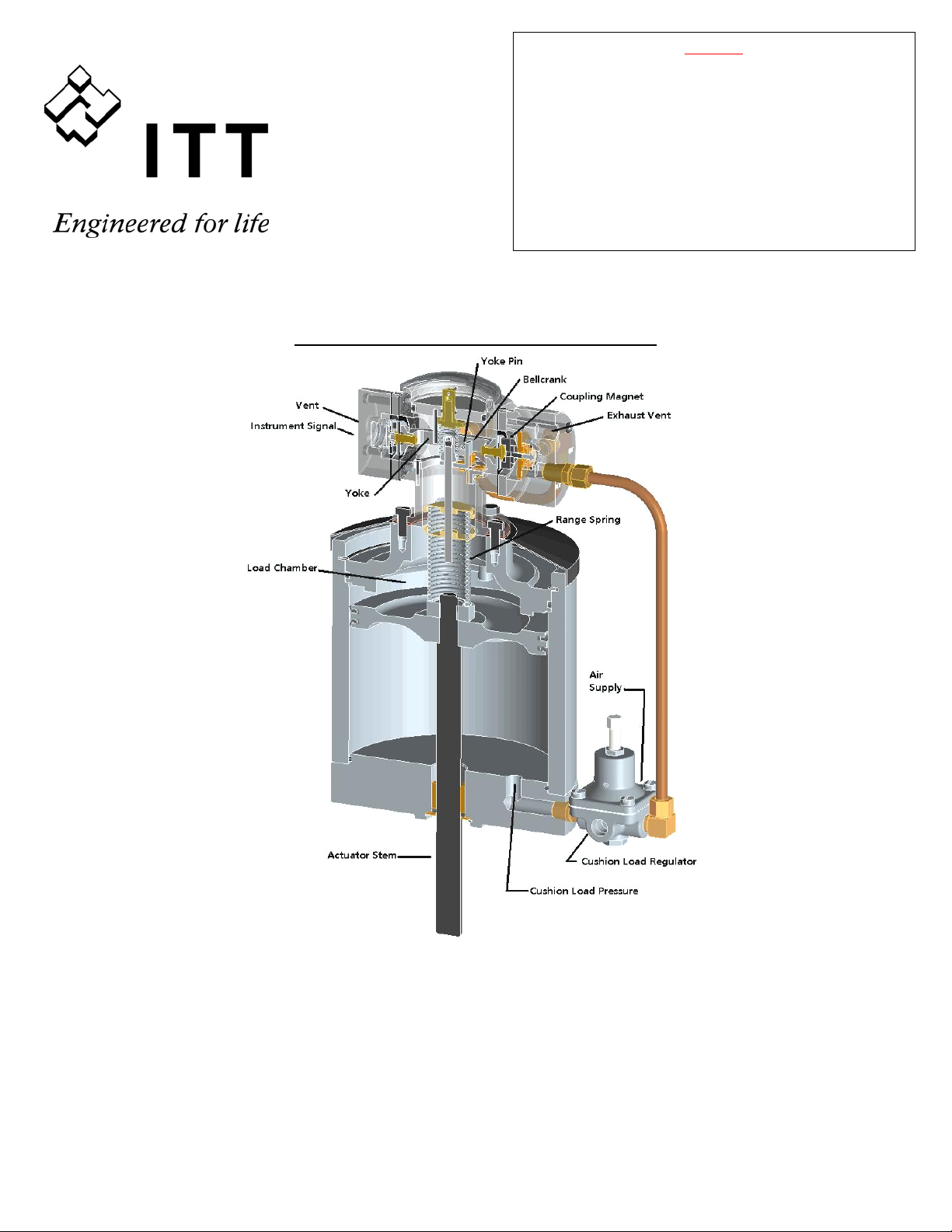

DOUBLE ACTING ACTUATOR WITH CUSHION LOAD

The use of a suitable cushion load regulator, such as the

Conoflow GH04, will drive double acting actuator operation.

Actuator

CG31 Positioner Instrument Signal

(manual or transducer)

Air Supply

Filter Regulator

P

GH04 Cushion

Load Regulator