35200860 Rev H

Ion-O-Vac

2. INTRODUCTION

The Ion-O-Vac sheet and web cleaning system consists of two main assemblies: The

vacuum head and the collection system. For web applications, two vacuum heads are

normally required. For sheet applications, one vacuum head is normally sufficient.

The vacuum head provides a uniform high velocity air flow at the orifice across the

entire width of the material being cleaned. A static eliminator is also provided with

web cleaners to remove static prior to the cleaning process. Contaminants removed

from the stock surface are carried to the collection system while the transporting air

is returned to the plant free of contaminants.

There are two basic types of vacuum heads:

• Mark I, vacuum head with a pair of stationary brushes (one left hand and

one right hand) or a pair of chad blades (for noncontact applications) One

static eliminator is normally provided to remove static before the cleaning

process.

• Mark IV, vacuum head with a combination of stationary brushes and a

rotary brush located at the orifice of the vacuum head. Due to the static

generated by the rotary brush, two static eliminators are normally provided

to remove static before and after the cleaning process.

Options Available for Web Applications

Adjustable Orifice: If the vacuum heads are to be installed on top of the web with

no roller underneath, this option is a must. On narrower web widths, this option will

enable the operator to close off the ends of the orifice to avoid losing the vacuum.

Manual or Pneumatic Retraction System: If the vacuum heads are to be installed

on top of an idler roller, this option will allow the operator to “swing” or “raise”

the vacuum heads for ease of webbing and to allow access to the idler rollers. Note

that Pneumatic Retraction Systems utilize air cylinders in place of the standard

Micrometer Adjustment feature.

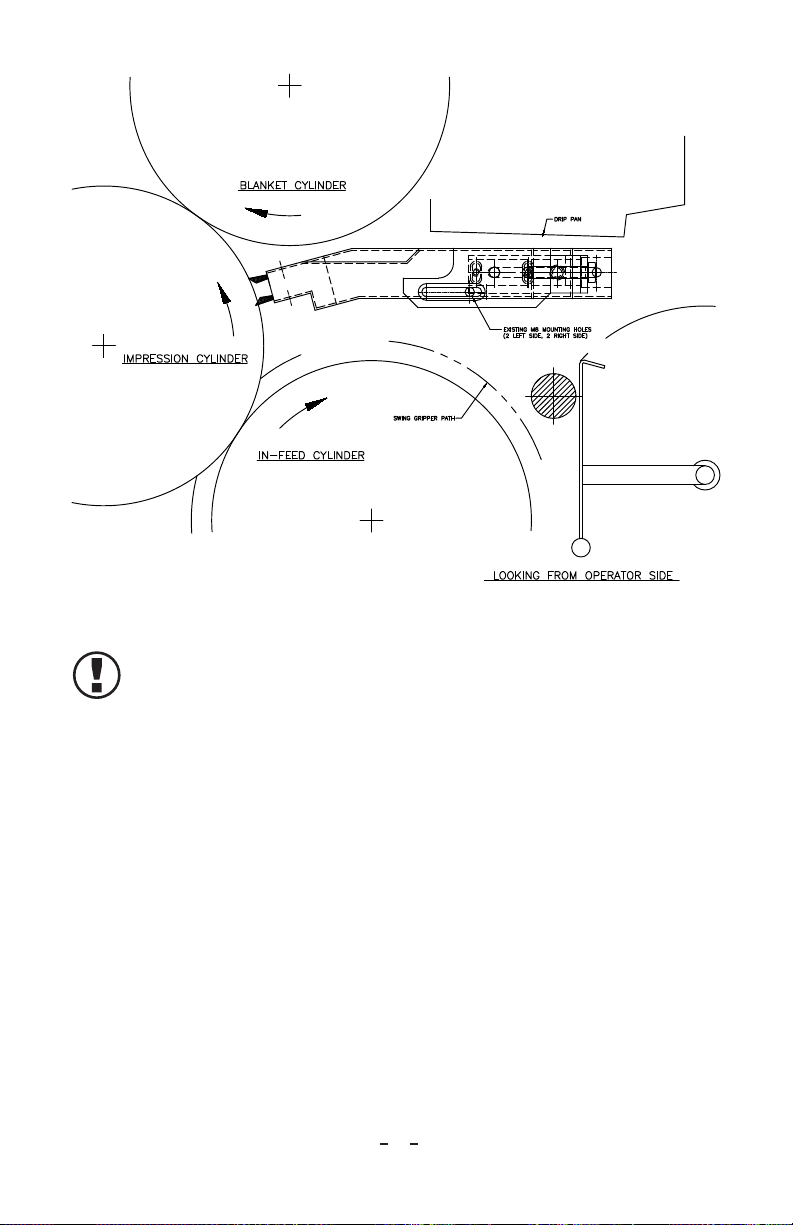

Options Available for Sheet Applications (Space Permitting)

Quick Release Brackets: This option allows the operator to easily remove the

vacuum head from the press by simply engaging the quick release pins and sliding

the vacuum head away from the impression cylinder.

Canister Collection System: Consists of a regenerative low CFM, high static

pressure blower and a collector known as a canister which contains a pre-filter and

a filter. This system also features an audible alarm which is activated when the filter

needs changing.