Diagraph - an ITW Company PA/4600 & PA/6000 User Manual

System Modules Page 7

System Modules

Stand P/N: 6160-329

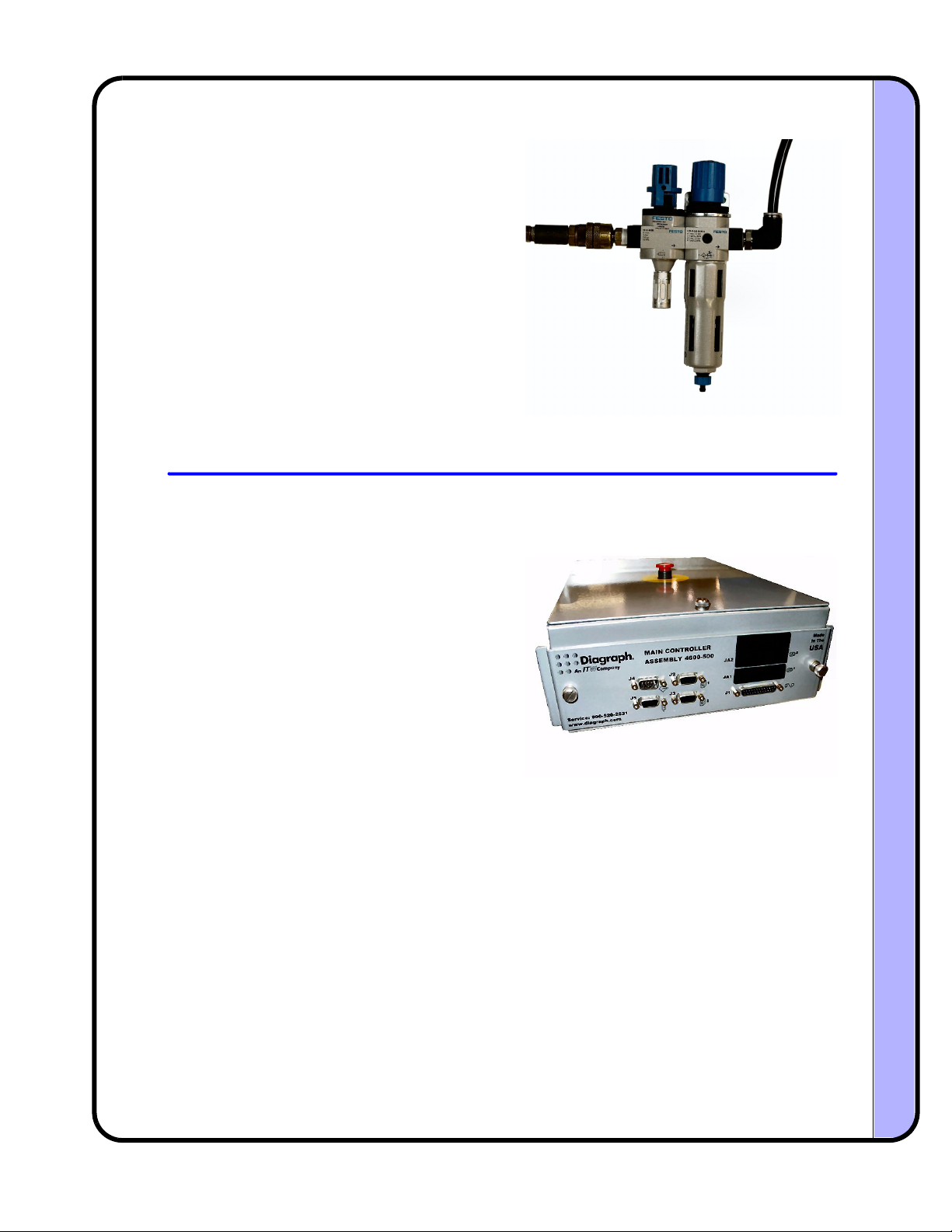

2.2 Pneumatics SubSystem

PAM (Pneumatic Air Manifold) P/N: 4600-701

Tamp Cylinder P/N: 4600-743 (10 inch), 4600-745 (20 inch)

ThestandholdstheyokeassemblyofthePA/

4600orPA/6000,andallowsthesystemtobe

orientatedinavarietyofpositionstosuit

applicationrequirements.Thestandemploys

ahandcranktosetverticalposition,anda

seriesofmountingpointsforitemssuchas:

warningtower,remoteuserinterface,and

inletfilter/regulator.Thestandcontainsthree

lockablecastersthatpreventrolling

movement,aswellasrotationalmovement.

Thecolumnofthestandisdesignedtobe

rotated,whichcanhelpinstallationswhere

thefrontlegofthet‐baseinterfereswith

existingequipment.

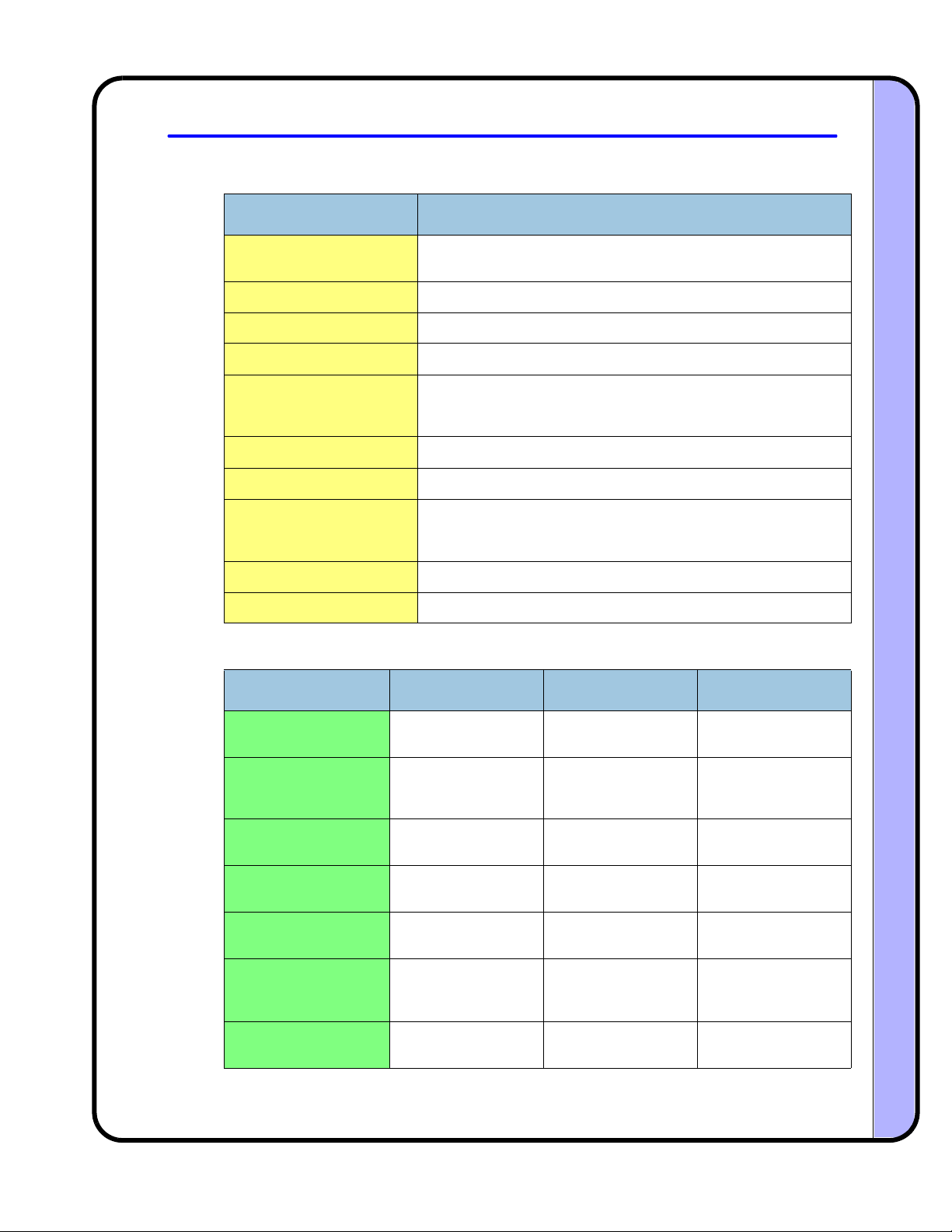

Theairmanifoldcontrolstheoperationof

thetampcylinderandthedeliveryofthe

labelfromtheprintertotheproduct.The

manifoldhastwopressureregulators,onefor

tamppressureandtheothercontrolsboth

vacuumandblow.Twoflowcontrolslimit

thevolumeofairgoingtotheairassistand

blowvalves.Therearetwopressuregauges

thatmonitorthepressuresetbythe

regulators.Apressuresensormonitorsthe

incomingairlevelanddisplaysitonadigital

readoutandbargraph.Anerroristriggeredif

theincomingpressuredropsbelowtheset

pointvalue.

Thetampcylinderemploysadual‐rod

designtoachieveveryhighspeedextension

andretraction,withoutrotation.Thetamp

cylinderextensionandretractionspeedis

controlledbymeansofthetamppressure

settingontheairmanifoldandtheflow

controlsonthecylinderbody.Anadjustable

aircushiononthetopofthecylinder

dampensthereturnenergy.Amagneticreed

switch,attachedtothetopofthecylinder,

detectstheimmediatereturnofthecylinder

toitshomeposition.