Aero 60/90 INDEX

Release 2.0 PAGE 3

Contents

AERO 60/90 .....................................................................................................................1

1.1. Safety......................................................................................................................... 5

1.1.1 Symbols and their Interpretations......................................................................... 5

1.1.2 Liability .................................................................................................................5

1.1.3 Warnings and Cautions........................................................................................6

1.1.4 Application Restrictions........................................................................................6

1.2. Installation Instructions.............................................................................................. 7

1.2.1 Selecting the location........................................................................................... 7

1.2.2 Connection to power ............................................................................................ 7

1.2.3 Connecting to Air Supply...................................................................................... 7

1.2.4 Setting Pressure Regulator.................................................................................. 8

1.2.5 Flow Controls .......................................................................................................8

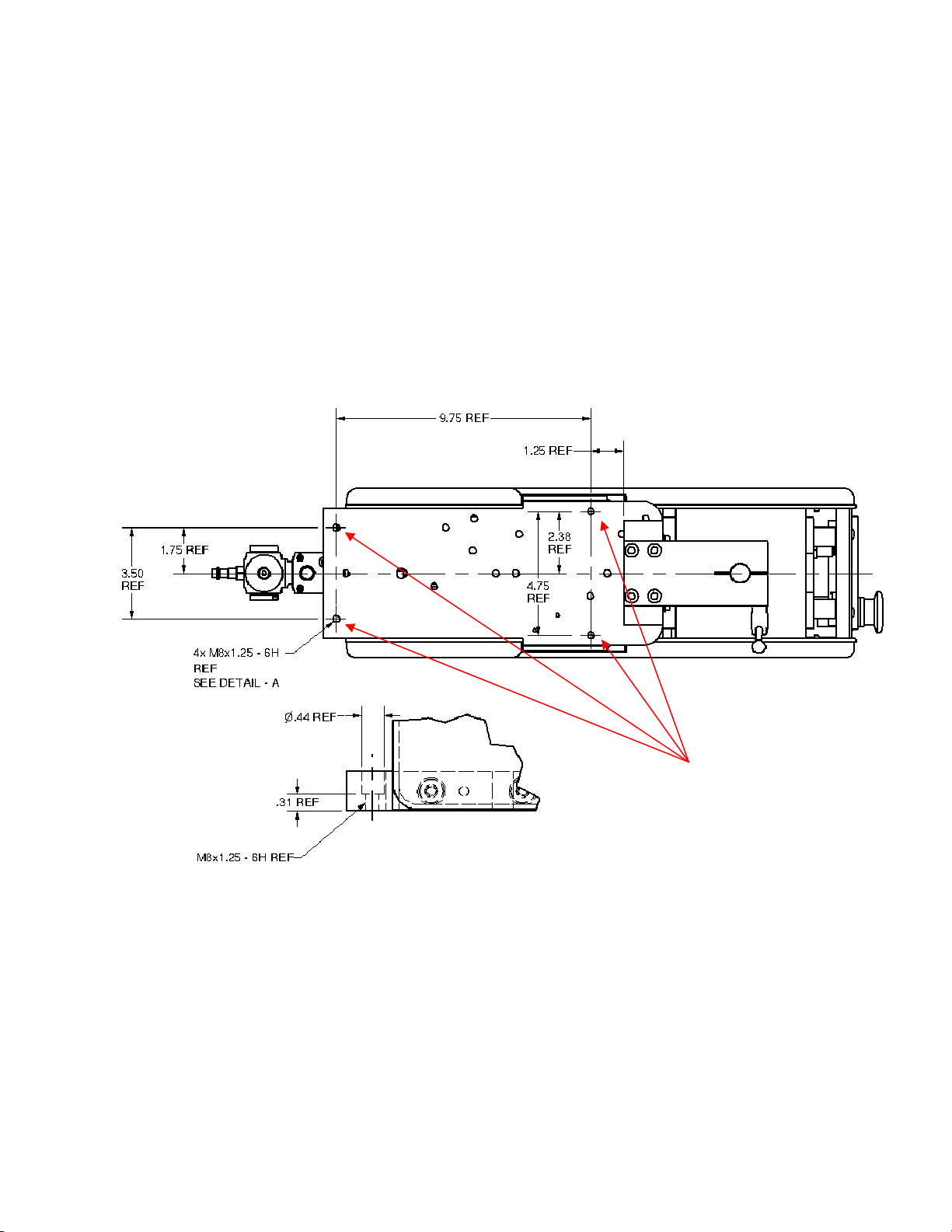

1.2.6 Mounting the Machine..........................................................................................9

1.3. Printer Operation ..................................................................................................... 10

1.3.1 Description of Ink Cup Tooling........................................................................... 10

1.3.2 Installation of the Cliché and Ink Cup.................................................................11

1.3.3 Removal of the Cliché and Ink Cup.................................................................... 12

1.3.4 Handling of the Ink Cup...................................................................................... 13

1.4. Operating Controls................................................................................................... 14

1.4.1 Description of the Operating Panel ....................................................................14

1.4.2 The Operating Control Functions....................................................................... 15

1.4.3 Screen Map........................................................................................................16