5

NE210

For protection against shock hazards as specified in VDE 0411 part

100, stranded conductors may only be connected using wire end

ferrules with insulating caps. Terminals which are not assigned in

the factory must not be otherwise assigned by the user. We

recommend shielding all encoder connecting leads and earthing

the shield at one end. Earthing at both ends is recommend to avoid

RF interference or if equipotential bonding conductors are installed

over long distances. Encoder connecting leads should not be laid in

the same trunking as the mains power supply cable and output

contact leads.

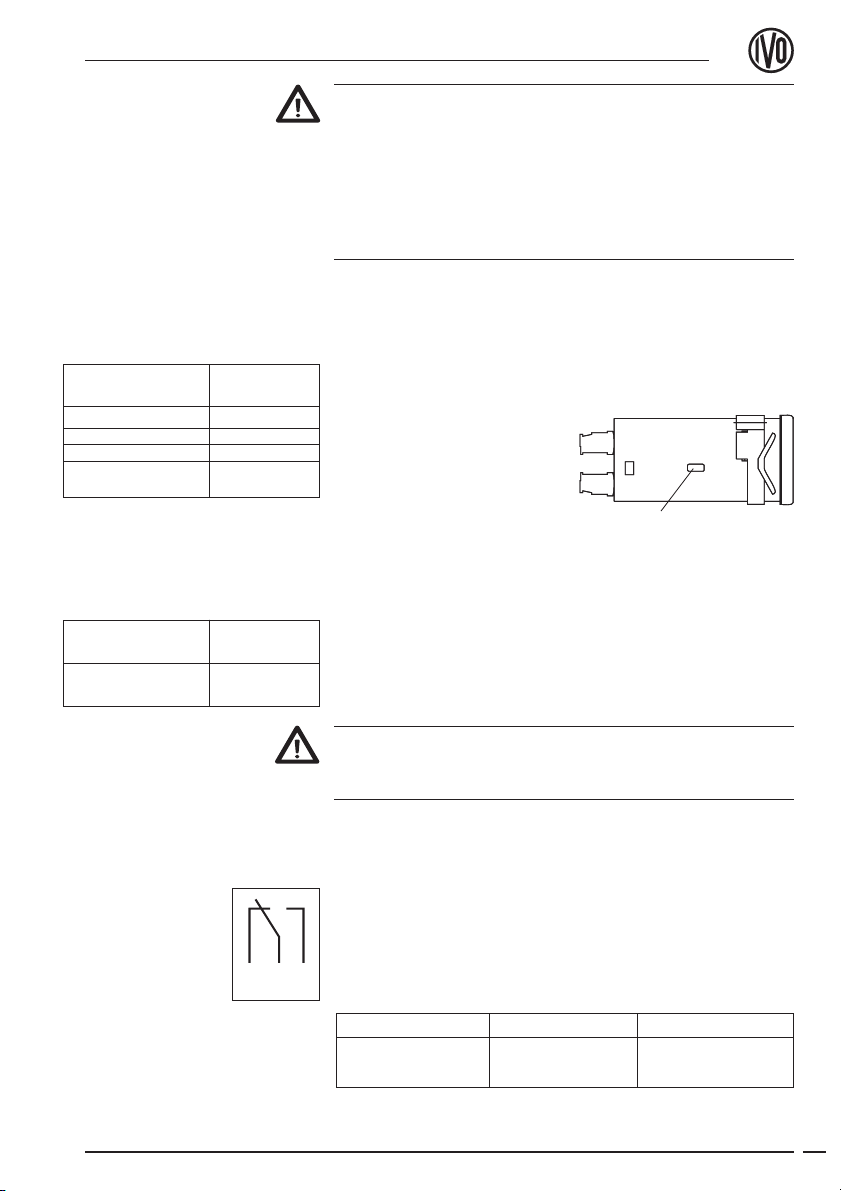

3.1 Connecting the power supply

AC voltage connection

It is possible to switch between two different alternating voltage

ratings (see adjoining table) by means of the voltage selector switch

at the side of the unit. The higher of the two alternating voltage

ratings (48V or 230V) is preset by the factory.

➜Set the required alternating

voltage with the voltage

selector switch.

➜Connect the alternating

voltage supply to terminals 2

and 3 in accordance with the

counter wiring diagram.

DC voltage connection

Connect an interference-free power supply, i.e. do not use it for the

parallel connection of drive systems, contactors, solenoid valves, etc.

➜Connect the DC voltage in accordance with the counter wiring

diagram.

Fire protection: Operate the instrument using the recommended

external fusing indicated in the terminal diagram. VDE 0411

specifies that 8A/150 VA(W) must never be exceeded in the event

of a fault.

3.2 Assignment signal output „relay contact“

Terminals 4, 5 and 6 form a no-potential changeover contact, which

can be assigned as a pulse or continuous contact in accordance with

the adjoining wiring diagram.

Implementation as a pulse or continuous signal is effected via DIP-

switch 2 and in the programming mode, line 12 (see 3.6). The pulse

time is programmed in the programming mode, line 2.

Counter connecting

Voltage selector

6 5 4

Power supply Recommended

AC voltage external fusing

24V ±10% 50/60 Hz M 400 mA

48V ±10% 50/60 Hz M 400 mA

115V ±10%50/60 Hz M 125 mA

230V +6/ -10 %

50/60 Hz M 125 mA

Power supply Recommended

AC voltage external fusing

24 V ±10 %

approx. 5 % RW M 400 mA

Max. switching Max. switching Max. switching

output voltage current

150 VA/30 W 250 V 1A