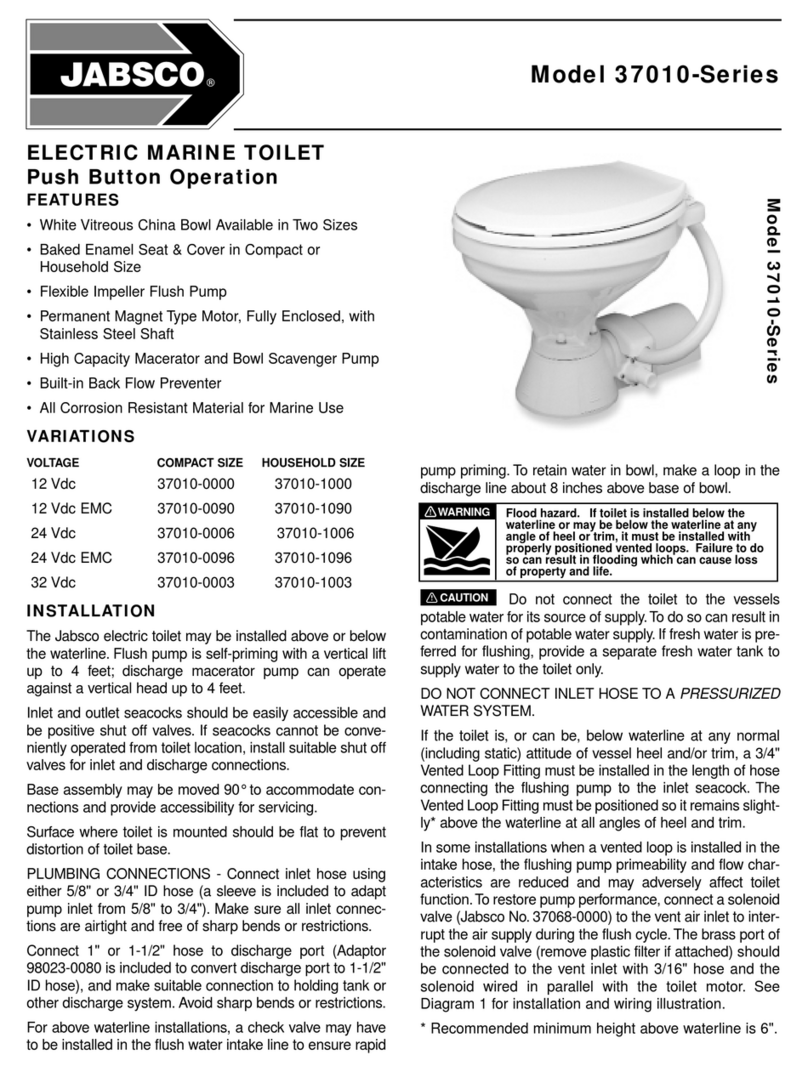

Positioningand Mounting

(continued)

smallbeadof silicone or latex sealantmay

be

appliedaroundbase

where itmntadsthe mounting surfaceto prevent moisNre

horn

getting

under the toilet base.

NOTICE: Donot use Polysulfidebase sealants becausethey may

chemically attackthe plasticwhich can resultinbreakage.

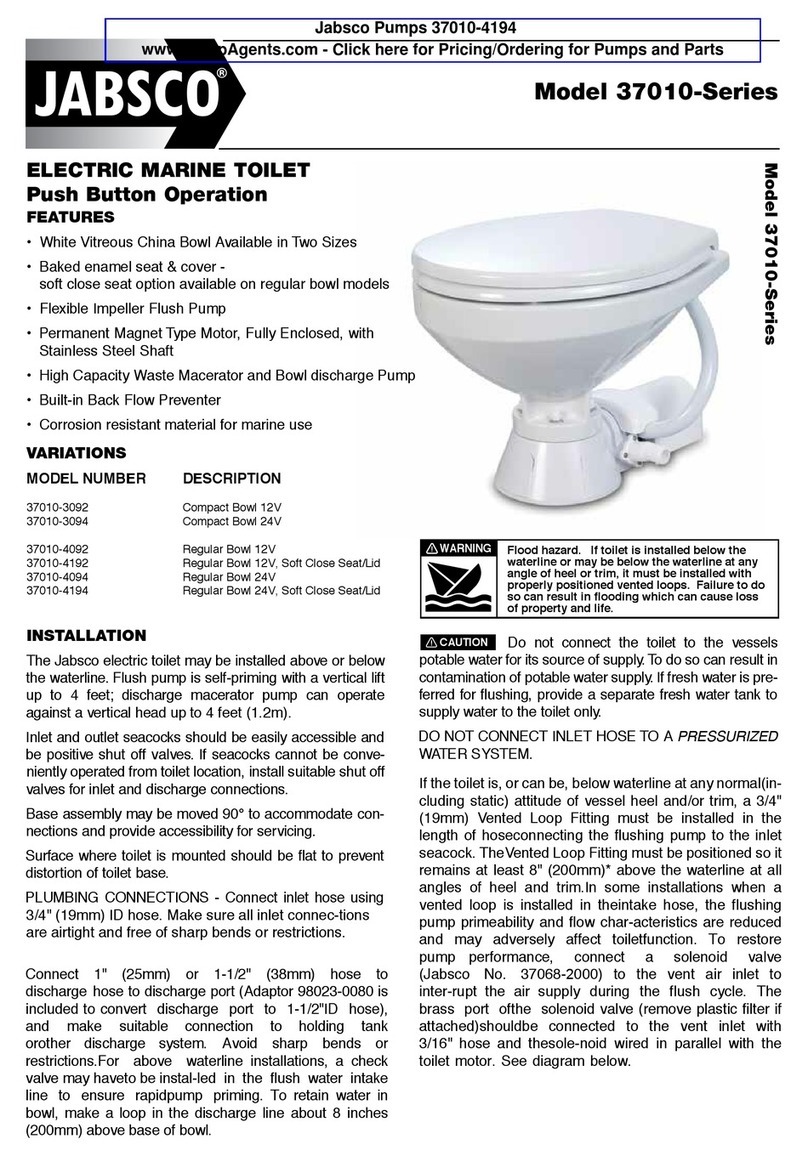

Plumbing

If

lnstalltng new Inletthm-hulllseacock,ensurethat 111s posltlonedon

a panof the hullwh~ch1s wettedat allanglosof heel or blm andhee of

water b~rbulenceat anv hull s&. If dischamina waste overboard

(che& legalrestrictio& for o;erboard dlschario): ensure discharge

thm-hulVseaco& Isboth aftof and hlgher than the lnlet mm-hull/

seacock. Allinlet

dmbiia

shwld

be

a minimwnof

34'

IDand

dlschargepumoinga mlnhumof 1-112'ID. All hose ends should be

doubledampedwith stainless steelhoseclamps

If

the toilot is above

waterline mute hoses to seacocks, holding tank or treatment device via

-

a routeas direct as poss~bleHowever, for maxlmum sealingeffoct on

the dlschargejokervalve. ~t

IS

recommended that the d~schargehoseis

loopedupwardabout

8'

above the discharmelbow before itdescends

to itsteril~tionpoint All bendsand elbows inplumbingshould

be

kept to a minimum. It shouldnot bo

necessary

to useany sealing

compoundwhen attaching hoses to the inlet

or

discharge porn.

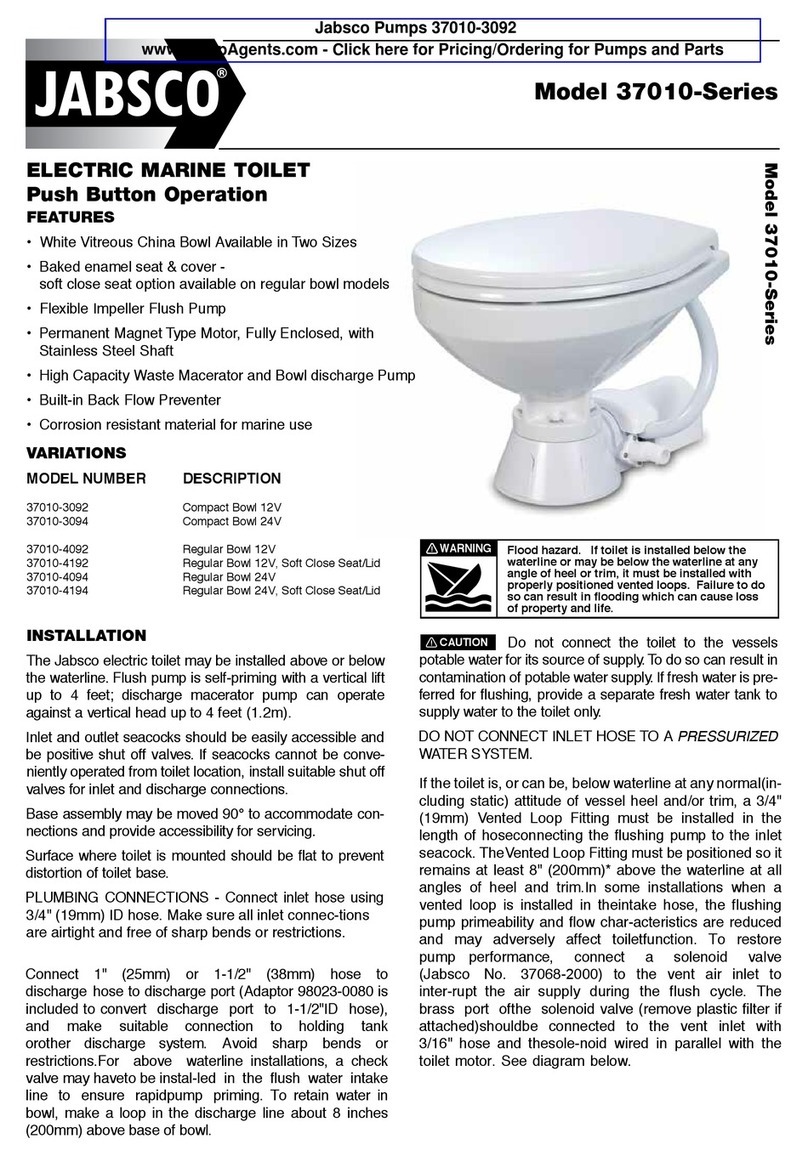

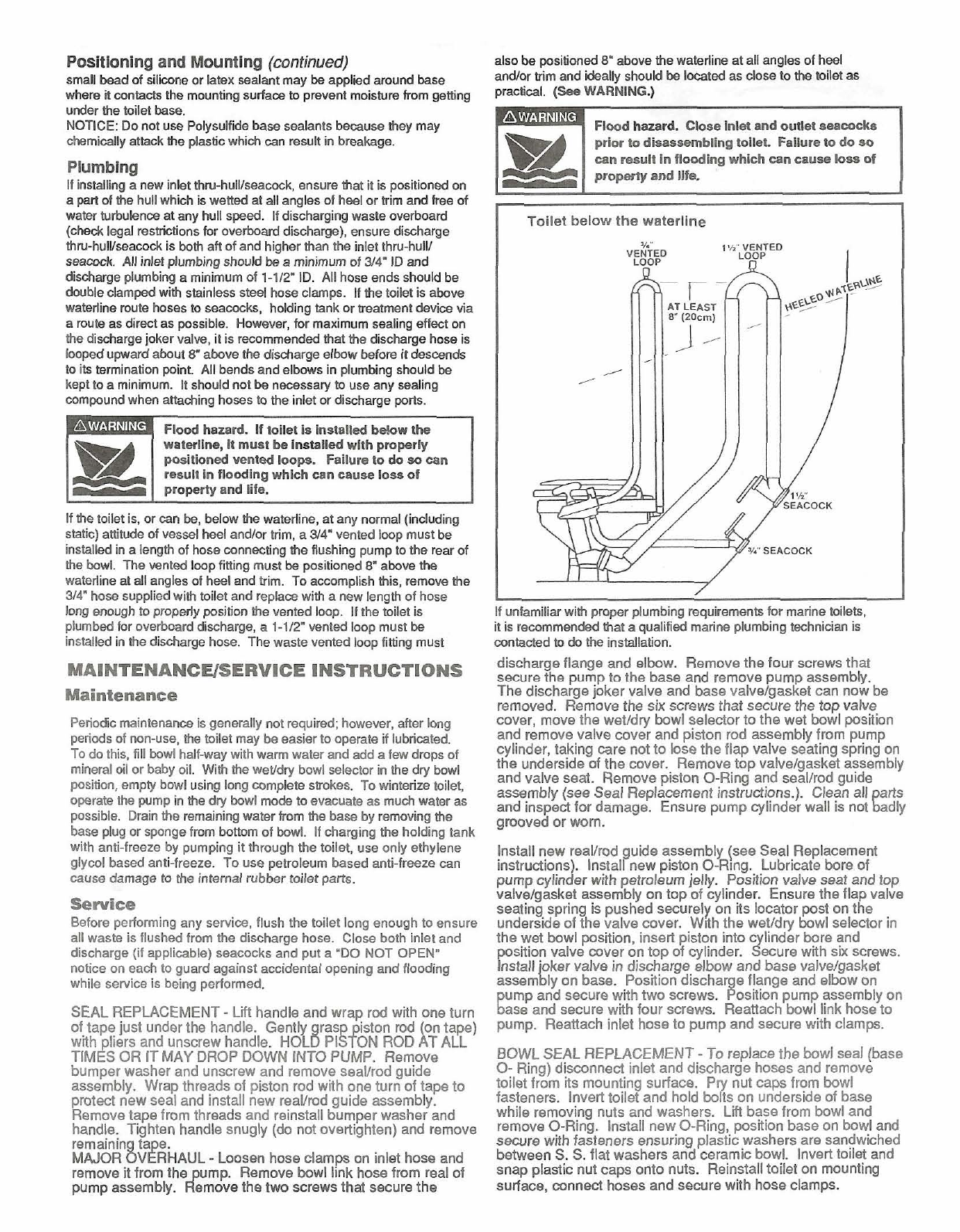

Floodhazard. Iftoilet isInstalledbelow the

waterline,

it

mustbeInstalledwith pmperly

positionedventedloops. Failureto do

so

can

result infloodingwhich cancauselossof

Ifthe toiletis,

or

can

be,

belowthe waterline, at any normal(induding

static) attitude of vessel heeland/or trim. a

314"

vented

IWD

must be

InstalledIn a longthof hosemnnecnngthe flush~ng iothe rear of

me bowl The vontedlwpflnlngmust

be

possoned

8'

above the

waterlineat allanales of heelandtrim. To amm~lishthis. removethe

314. hosesuppllodwlth toilet andreplacswlth a new lengiof hose

longenough to properly positionthe vented loop.

If

the toilet is

plumbedforoverboarddischarge, a 1-112" vented loop must

be

installedin the discharge hose. The waste vented loop fitting must

MAlNTENANCElSERVlCE INSTRUCTIONS

Maintenance

Periodicmaintenanceis generally notrequired;however, after long

periodsof non-use, the toilet may beeasier to operate if lubricated.

To do this, fill bowlhalf-waywith warm water and addafew dmps of

mineraloil or baby oil. With

the

wetldw bowl selectorinthe dw bowl

poslbon,empty bowluslnglongcomplete strokes To wlntenzi tollet.

operate the pump Inthe dry bowl mo& to evacuate as much water as

possible. Drainthe remainingwater from the base by removingthe

baseplugor spongefrom bottomof bowl. if charging the holding tank

with anti-freeze by pumpingitthrough the toilet, use only ethylene

glycol basedanti-freeze. To use petroleum based anti-freezecan

cause damage to the internalrubber toilet parts.

Service

Before ~erforminaanv service. flush the toilet lona enouoh to ensure

allwade 1s flushid frbm the dlschargo hose ~lo;e bothlnlet and

dlscharge (11appltcaolc)seacocks and put a 'DO NOT OPEN"

noticeon each to guardagainstaccidentalopeningandflooding

while service is being performed.

SEAL REPLACEMENT

-

Ltfl handle andwrap rod with one t~rn

o! tape just under the handle. Gently ras iston rod on lape)

w th Cers and unscrew handle.

HOLB

PI~ON

ROD

A

TALL

TIMI&

OR ITMAY DROP DOWN INTOPUMP. Remove

bumper washer and unscrew and remove seallrod guide

assembly. Wrap threads

01

piston rod with one turn of tape to

protect new seal and install new reallrodguide assemoly.

Removetape from threads and reinstallbumper washer and

handle. Tiahten handle snugly (do not overlighten) and remove

-.

. -.

remainin fa e.

MPJOR

~V~RHAUL

-

Loosen hoseclam~son inlet hose and

remove it from the ump Remove bowl link hosefrom real of

pump assembly. &move the two screws that secure the

also

be

positioned

8'

above me waterline at all angles of heel

ancVor trim and ideally should

be

located

as

closeto the toilet

as

~racbl.

(See

WARNING.)

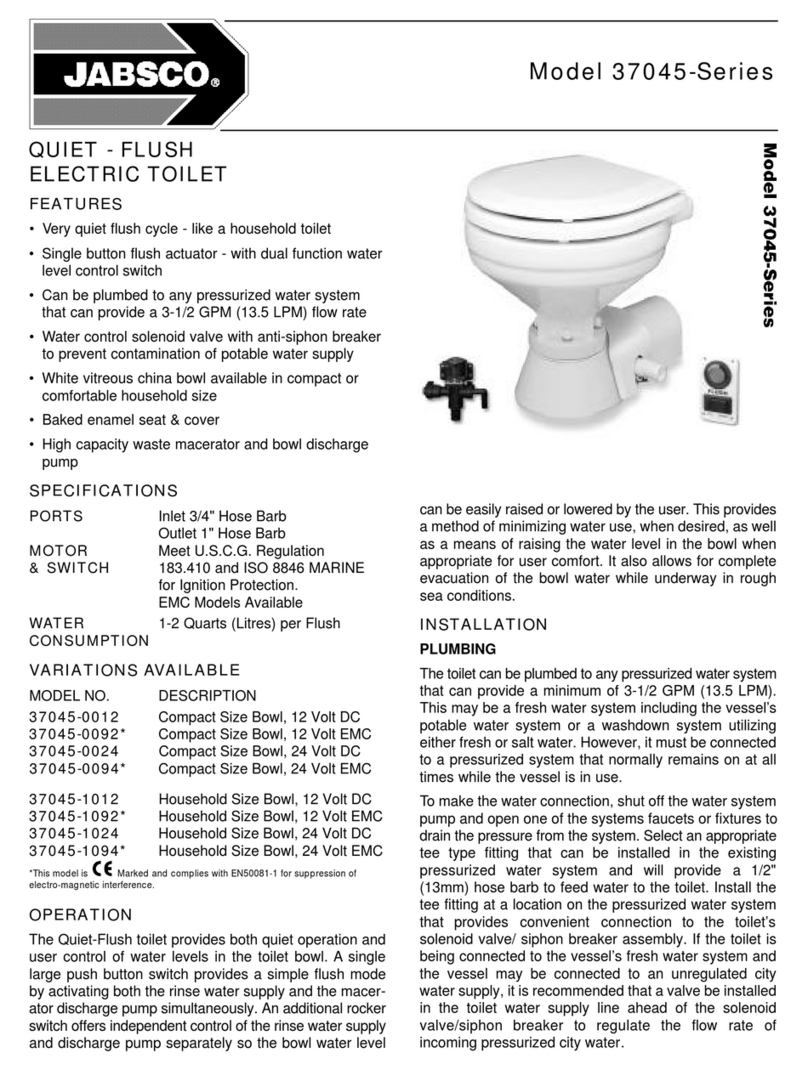

Floodhazard. CloseInlet andoutlet seearcks

prlor todisassembllngtoilet Failuretodo

so

canresultinfloodingwhich cancauselossof

propertyandUfe.

I

Toilet below the

waterline

I

Y."

VENTEO

I'/<'

VENTEO

LOOP

LOOP

n

I

I

I

/

If unfamiliar with proper plumbing requirementsformarine toilets.

it is recommendedthat aqualifiedmarineplumbingtechnician is

contactedto

&

the installation.

discharge flange and elbow. Removethefour screwsthat

secure the pumpto the base and remove pump assembly.

The dischargejoker valve and basevalvelgasket can now be

removed. Removethe six screws that secure the topvalve

cover, move the wetldry bowl selectortothe wet bowlposition

and remove valve cover and piston rod assembly from pump

cylinder, taking care not to losetheflap valve seating spring on

the underside

of

the cover. Removetopvalvelgasket assembly

andvalve seat. Remove piston 0-Ring and seallrod guide

assembly (see Seal Replacement instructions.). Clean all

and inspect for damage. Ensure pumpcylinder wall isnot

g$

groovedor worn.

lnstall new reallrod guide assembly (see Seal Replacement

instruct~ons).Install new plston0-R~ng.Lubricateboreof

pumpcylinder with petroleumjelly. Position valve

seat

andtop

valvelaasket assemblv on topof cvlinder. Ensure the flap valve

seating spring ispushbdsecurely on its locator post onthe

underside of the valve cover. With the wetld~bowl selector in

~

~

~~

~

the wet bowlposit;on, inserl piston into lind6r bore and

'3

postionvalve cover on top of qlinder. ec-re witn six screws.

Install oker valve

in

discharge e.bow and base varve/gasket

assembly on base. Positiono.scharge flange and elbow on

gump and secure with two screws. Positionpump assembly on

ase and secure with four screws. Reattachbowl link hoseto

pump. Reattach inlet hoseto pumpandsecure with clamps,

BOWL SEAL REPLACEMENT

-

To replacerhe bowl seal (base

0-

Rng)disconnect inlet and discharge hoses and remove

toilet from its mounting surface. Pry nut caps from bowl

fasteners. Inverttoilet and hold bolts on underside of base

while removing nuts and washers.

Lii

basefrom bowl and

remove 0-Rina. Install new 0-Rina. wsitionbaseonbowl and

secure with faienersensuring plagi~cwashers are sandw~cned

between S. S. flat washers andceramic bowl. lnventoilet and

snap plastic nut caps onto nuts. Reinstall toilet on mount~ng

sufiace, connect hoses and secure with hoseclamps.