ELECTRICAL CONNECTIONS - Select a location for the

switch and instruction plate, making sure wire leads from

both the toilet and power source can be routed to the

switch. Ensure the panel where installing switch is no

more than 1" thick. Drill a 5/8" mounting hole and install

switch and instruction plate. Use stranded copper wire of

the correct size (determined from the electrical specifica-

tions chart) to connect one side of the switch to the pos-

itive power source.An appropriate size fuse or equivalent

circuit breaker (determined from electrical specifications

chart) must be installed in the positive power lead within

seven inches of the power source.Connect the other side

of the switch to the orange (positive) motor lead. Connect

the black (negative) motor lead to the negative side of the

battery or grounded buss bar.

NOTICE: Correct motor polarity (orange to positive, black

to negative) is important. Reverse polarity can damage

motor and void warranty. Full voltage at the motor is

required to properly operate the Electric Toilet.The toilet

must be wired in a circuit independent of all other acces-

sories.

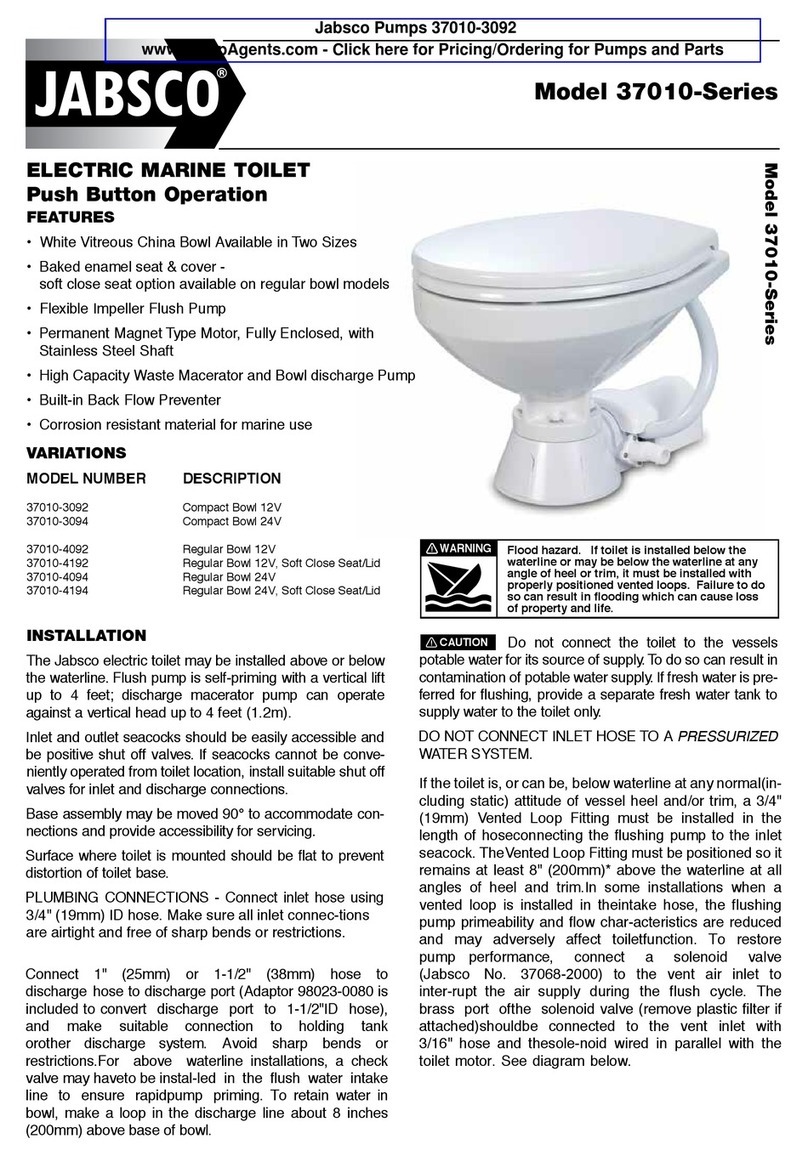

ELECTRICAL SPECIFICATIONS

AMP FUSE WIRE SIZE PER FEET OF RUN*

VOLTAGE DRAW SIZE 0'-10' 10'-15' 15'-25' 25'-40' 40'-60'

12 Vdc 16 25 #12 #10 #10 #8 #6

24 Vdc 8 15 #16 #14 #12 #10 #10

32 Vdc 6 10 #16 #16 #14 #14 #12

* Length of run is total distance from power source to product and back to ground.

OPERATING INSTRUCTIONS

Make sure inlet and outlet seacocks are all open; push but-

ton to operate.Operate until bowl is completely flushed and

discharge pump has scavenged water from bottom of bowl.

The Jabsco electric marine toilet will provide years of trou-

blefree service if properly used.It will handle waste and toi-

let tissue. It will NOT handle rags, sanitary napkins or hard

solid objects.

If bowl does not pump out and begins to fill, partially close

inlet valve until bowl is cleared and completely pumped out.

Then operate for a few seconds with both valves open to

clear entire toilet and discharge system. For maximum

safety, when toilet is not in use or vessel is unattended,

close both the inlet and discharge seacocks.

To drain for winter lay-up, close inlet valve and operate for

a few seconds until all water is pumped out.

After long periods of non-use, toilet and pump may dry out.

To ease initial start-up, put about one quart of water in bowl

and let stand awhile before initial use.

DISASSEMBLY

Disconnect pumping inlet and discharge hoses. Remove

four screws, Key No.25, pull out complete motor, pump and

macerator assembly. If assembly does not slide out easily,

push forward and pull back sharply several times to free

macerator housing from base.

Remove discharge port, Key No. 12, and joker valve.

Unscrew chopper plate, Key No. 14, by turning counter-

clockwise, facing plate. Prevent shaft from turning by plac-

ing screwdriver in discharge port and locking centrifugal

impeller blade. Remove macerator housing. Loosen

impeller set screw and slide impeller off motor shaft.

Remove four flathead screws and two washers, Key Nos.

20, 21, & 22. Remove the plastic wearplate, Key No. 23,

with sealing sleeve, Key No. 19, and gasket, Key No. 26.

Slide pump assembly off motor shaft. Replace all worn or

damaged parts, clean remaining parts.

ASSEMBLY

Press seal into body with lip facing impeller; be careful

not to cock seal in bore. Install pump body on motor and

position on register. Lubricate impeller bore with pump

grease and install impeller. Position the gasket against

the body and install the wearplate ensuring the two plas-

tic sealing washers are under the heads of the top and

bottom screws. NOTE: The current plastic wearplate

supercedes the earlier brass wearplate and with it the

stainless steel wearplate is no longer used.Slide the rub-

ber sealing sleeve on the motor shaft and push it into its

recess in the wearplate. Relocate centrifugal impeller on

shaft, about 1/8" from the wearplate, and tighten set

screw. Place macerator housing over shaft and centrifu-

gal impeller, put lock washer on end of shaft and screw

chopper plate on shaft and tighten. Install O-ring in O-

ring groove in wearplate surface, a little grease will help

hold in place, make sure inside body surfaces are clean,

line up slot in base with key on macerator housing, slide

pump assembly into base and tighten with the four

screws.Turn motor on for one or two seconds to be sure

centrifugal impeller is free.