EQUIVALENT CIRCUIT BREAKER DETERMINED FROM ELECTRICAL

SPECIFICATIONS CHART MUST BE INSTALLED IN THE POSITIVE

POWER LEAD WITHIN SEVEN INCHES OF THE POWER SOURCE

#ONNECT THE OTHER SIDE OF THE SWITCH TO THE ORANGE

POSITIVE MOTOR LEAD #ONNECT THE BLACK NEGATIVE

MOTOR LEAD TO THE NEGATIVE SIDE OF THE BATTERY OR

GROUNDEDBUSSBAR

./4)#% #ORRECT MOTOR POLARITY ORANGE TO POSITIVE

BLACK TO NEGATIVE IS IMPORTANT 2EVERSE POLARITY CAN

DAMAGE MOTOR AND VOID WARRANTY &ULL VOLTAGE AT THE

MOTORISREQUIREDTOPROPERLYOPERATETHE%LECTRIC4OILET

4HETOILETMUSTBEWIREDINACIRCUITINDEPENDENTOFALL

OTHERACCESSORIES

ELECTRICAL SPECIFICATIONS

AMP FUSE WIRE SIZE PER FEET OF RUN*

VOLTAGE DRAW SIZE 0'-10' 10'-15' 15'-25' 25'-40' 40'-60'

6DC

6DC

,ENGTHOFRUNISTOTALDISTANCEFROMPOWERSOURCETOPRODUCTANDBACKTOGROUND

OPERATING INSTRUCTIONS

-AKE SURE INLET AND OUTLET SEACOCKS ARE ALL OPEN PUSH

BUTTON

TOOPERATE/PERATEUNTILBOWLISCOMPLETELYFLUSHED

ANDDISCHARGEPUMPHASSCAVENGEDWATERFROMBOTTOMOF

BOWL

4HE *ABSCO ELECTRIC MARINE TOILET WILL PROVIDE YEARS OF

TROUBLEFREE SERVICE IF PROPERLY USED )T WILL HANDLE WASTE

ANDTOILETTISSUE)TWILL./4HANDLERAGSSANITARYNAPKINS

ORHARDSOLIDOBJECTS

)FBOWLDOESNOTPUMPOUTANDBEGINSTOFILLPARTIALLYCLOSE

INLET VALVE UNTIL BOWL IS CLEARED AND COMPLETELY PUMPED

OUT4HENOPERATEFORAFEWSECONDSWITHBOTHVALVESOPEN

TOCLEARENTIRETOILETANDDISCHARGESYSTEM&ORMAXIMUM

SAFETYWHENTOILETISNOTINUSEORVESSEL IS UNATTENDED

CLOSEBOTHTHEINLETANDDISCHARGESEACOCKS

4ODRAINFORWINTERLAYUPCLOSEINLETVALVEANDOPERATEFOR

AFEWSECONDSUNTILALLWATERISPUMPEDOUT

!FTER LONG PERIODS OF NONUSE TOILET AND PUMP MAY DRY

OUT4OEASEINITIALSTARTUPPUTABOUTONEQUARTOFWATER

INBOWLANDLETSTANDAWHILEBEFOREINITIALUSE

DISASSEMBLY

!

WARNING &LOODHAZARD#LOSEINLETANDOUTLETSEACOCKSPRIORTO

DISASSEMBLING TOILET &AILURE TO DO SO CAN RESULT IN

FLOODINGWHICHCANCAUSELOSSOFPROPERTYANDLIFE

$ISCONNECTPUMPINGINLETANDDISCHARGEHOSES2EMOVE

FOURSCREWS+EY.OPULLOUTCOMPLETEMOTORPUMP

ANDMACERATORASSEMBLY)FASSEMBLYDOESNOTSLIDEOUT

EASILYPUSHFORWARDANDPULLBACKSHARPLYSEVERALTIMES

TOFREEMACERATORHOUSINGFROMBASE

2EMOVE DISCHARGE PORT +EY .O AND JOKER VALVE

5NSCREWCHOPPERPLATE+EY.OBYTURNINGCOUNTER

CLOCKWISE FACING PLATE 0REVENT SHAFT FROM TURNING BY

PLACING SCREWDRIVER IN DISCHARGE PORT AND LOCKING

CENTRIFUGAL IMPELLER BLADE 2EMOVE MACERATOR HOUSING

,OOSEN IMPELLER SET SCREW AND SLIDE IMPELLER OFF MOTOR

SHAFT

2EMOVEFOURFLATHEADSCREWSANDTWOWASHERS+EY.OS

2EMOVETHEPLASTICWEARPLATE+EY.O

WITHSEALINGSLEEVE+EY.OANDGASKET+EY.O

3LIDEPUMPASSEMBLYOFFMOTORSHAFT2EPLACEALLWORNOR

DAMAGEDPARTSCLEANREMAININGPARTS

ASSEMBLY

0RESSSEALINTOBODYWITHLIPFACINGIMPELLERBECAREFUL

NOTTOCOCKSEALINBORE)NSTALLPUMPBODYONMOTORAND

POSITIONONREGISTER,UBRICATEIMPELLERBOREWITHPUMP

GREASEANDINSTALLIMPELLER0OSITIONTHEGASKETAGAINST

THE BODY AND INSTALL THE WEARPLATE ENSURING THE TWO

PLASTICSEALINGWASHERSAREUNDERTHEHEADSOFTHETOP

ANDBOTTOMSCREWS./4%4HECURRENTPLASTICWEARPLATE

SUPERCEDESTHEEARLIERBRASSWEARPLATEANDWITHITTHE

STAINLESS STEEL WEARPLATE IS NO LONGER USED 3LIDE THE

RUBBER SEALING SLEEVE ON THE MOTOR SHAFT AND PUSH IT

INTO ITS RECESS IN THE WEARPLATE 2ELOCATE CENTRIFUGAL

IMPELLER ON SHAFT ABOUT FROM THE WEARPLATE AND

TIGHTENSET SCREW0LACE MACERATORHOUSING OVER SHAFT

ANDCENTRIFUGALIMPELLERPUTLOCKWASHERONENDOFSHAFT

AND SCREW CHOPPER PLATE ON SHAFT AND TIGHTEN )NSTALL

/RING IN /RING GROOVE IN WEARPLATE SURFACE A LITTLE

GREASE WILL HELP HOLD IN PLACE MAKE SURE INSIDE BODY

SURFACES ARE CLEAN LINE UP SLOT IN BASE WITH KEY ON

MACERATORHOUSINGSLIDEPUMPASSEMBLYINTOBASEAND

TIGHTEN WITH THE FOUR SCREWS4URN MOTOR ON FOR ONE OR

TWOSECONDSTOBESURECENTRIFUGALIMPELLERISFREE

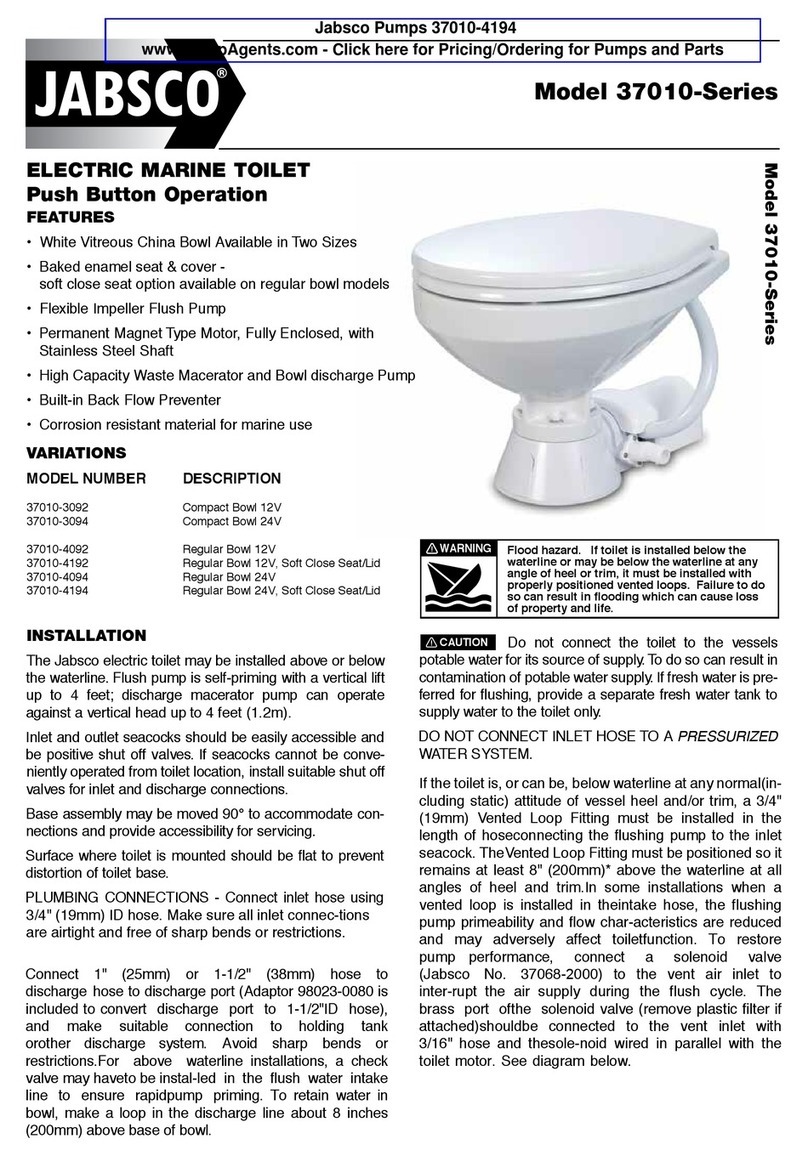

./4%4HESWITCHONTHESIDEOF

THE SOLENOID IS INACTIVE AND WILL

NOTAFFECTOPERATION

-

+

-

DISCHARGE

TO

NEGATIVE

TO

POSITIVE

TO

NEGATIVE VENTED LOOP

Heeled

Waterline

Static

VIEW A

SWITCH

INLET

VIEW A

VENT TO

ATMOSPHERE

1/4" BSP

BRASS

CONNECTOR

(Screws on to

Vented Loop) Use PTFE tape

to seal

connector

onto Vented

Loop

ELECTRICAL

CONNECTIONS

$IAGRAM