JABSCO 50270 Series Operating instructions

Other JABSCO Water Pump manuals

JABSCO

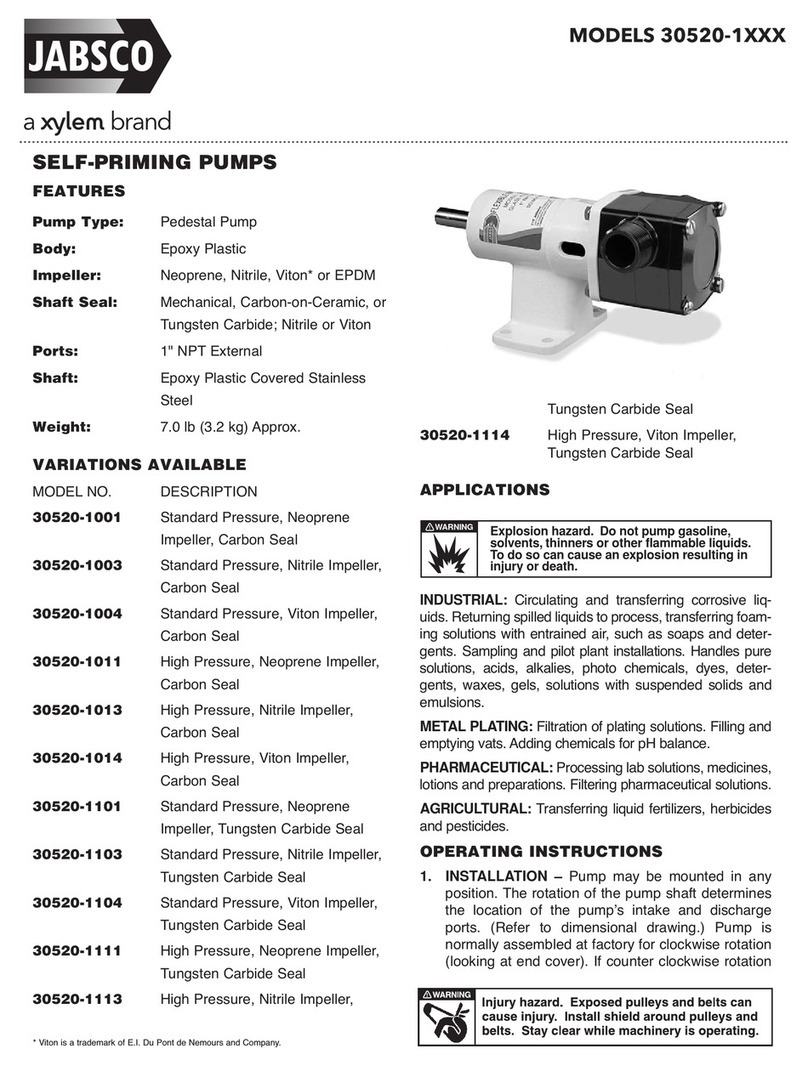

JABSCO 30520-1001 User manual

JABSCO

JABSCO 6400 Series User manual

JABSCO

JABSCO 30560-0 Series User manual

JABSCO

JABSCO 36680-2 Series User manual

JABSCO

JABSCO 50870 Series User manual

JABSCO

JABSCO 12490 Series User manual

JABSCO

JABSCO CENTRI PUPPY 18510-000 Series User manual

JABSCO

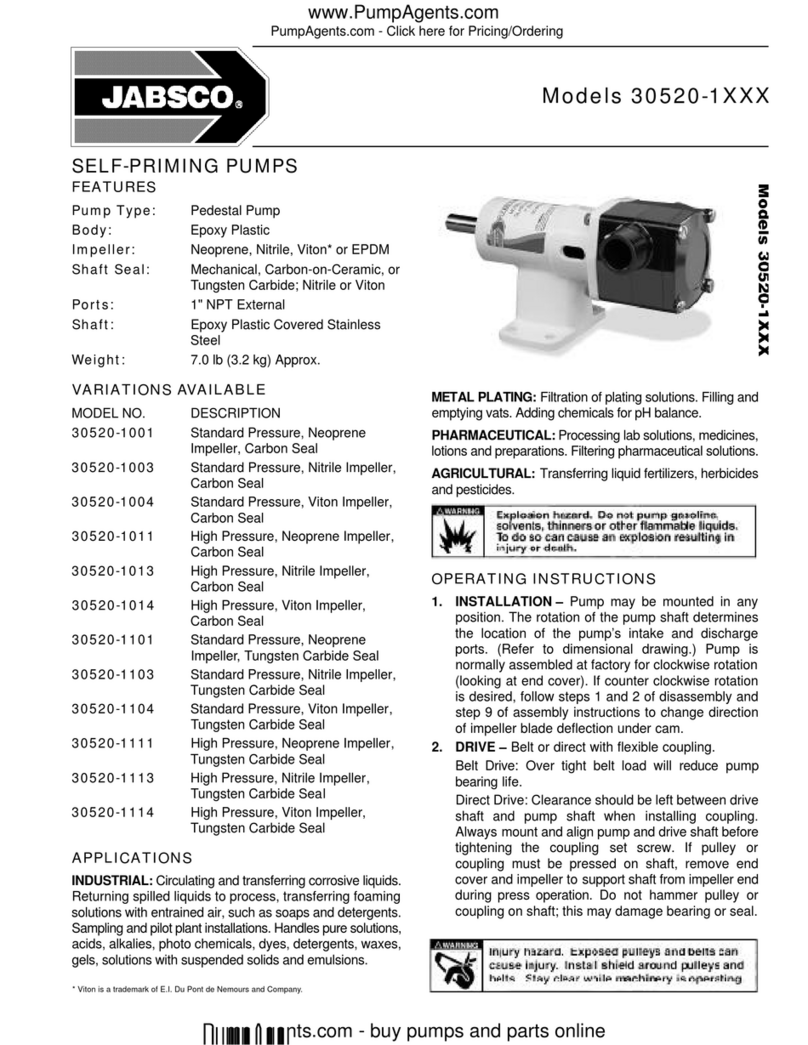

JABSCO 30520-1 Series User manual

JABSCO

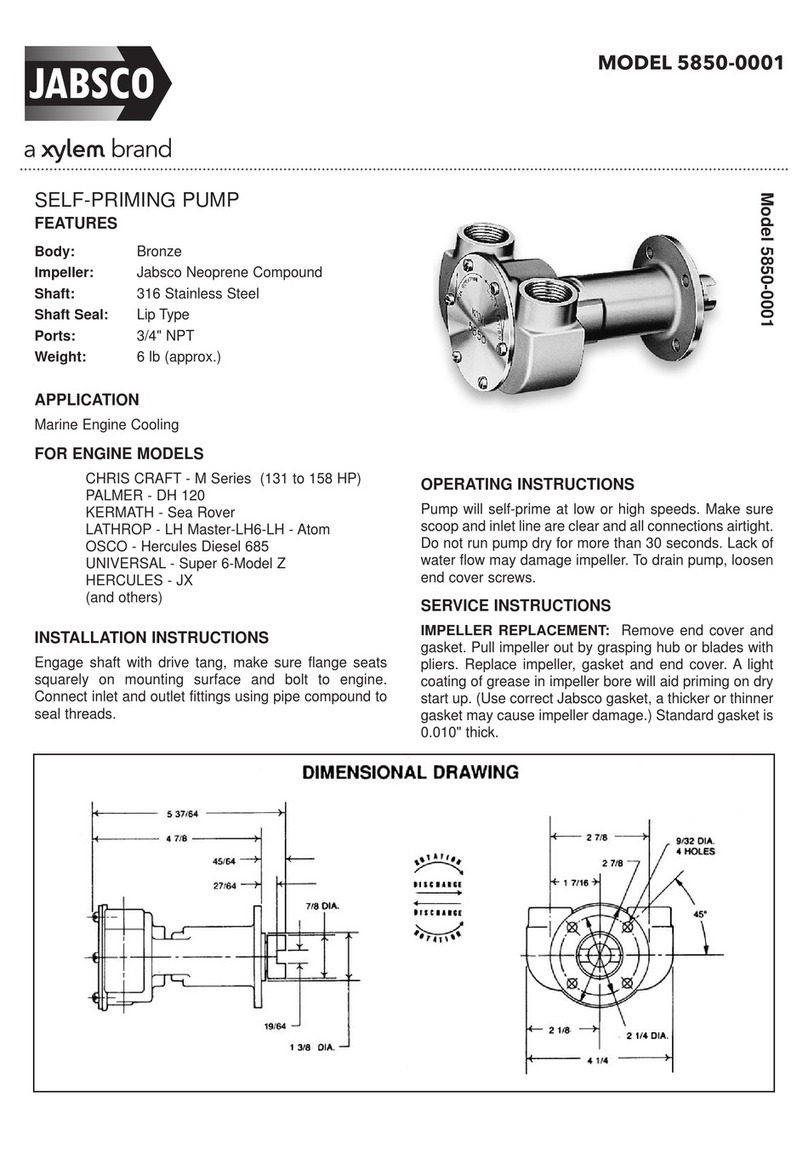

JABSCO 5850-0001 User manual

JABSCO

JABSCO 32605 Series User manual

JABSCO

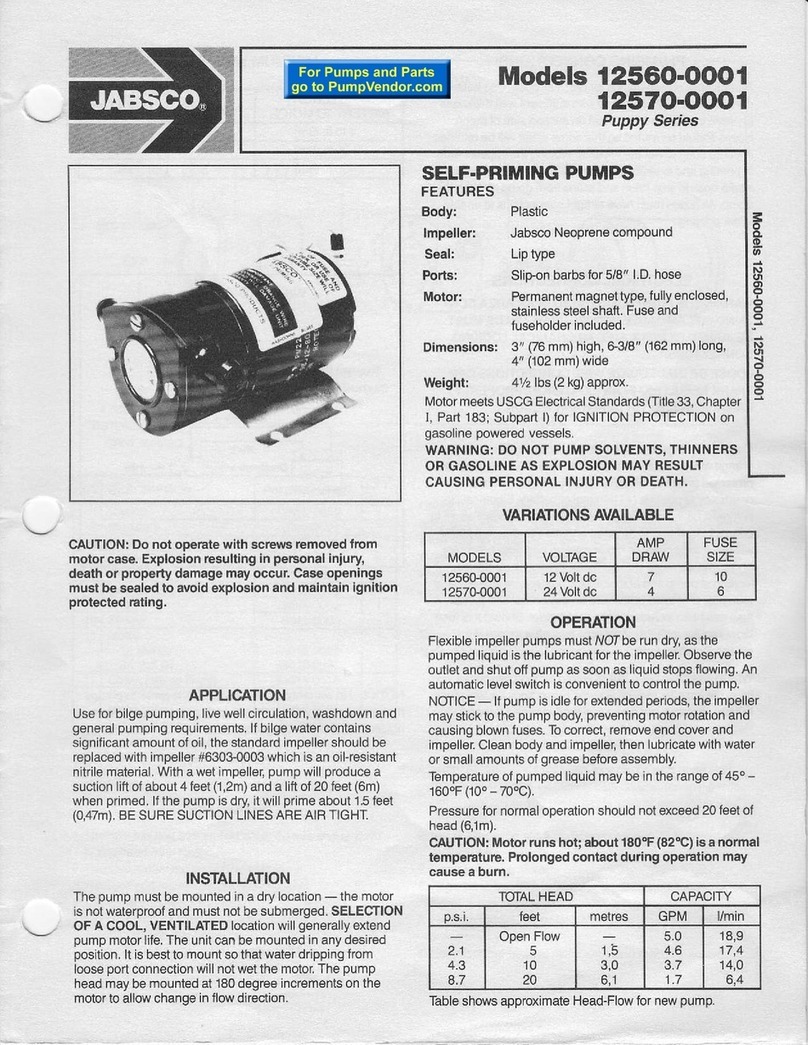

JABSCO Puppy 12560-0001 User manual

JABSCO

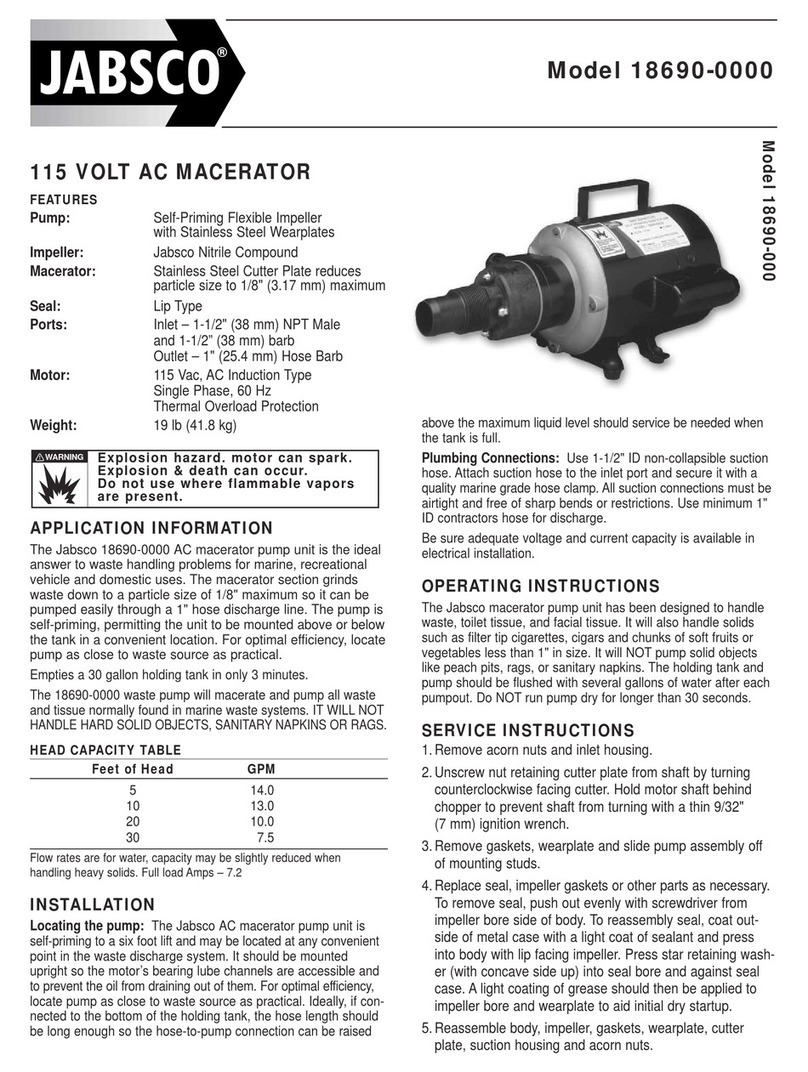

JABSCO 18690-0000 User manual

JABSCO

JABSCO 59510-Series User manual

JABSCO

JABSCO 29200-0120 User manual

JABSCO

JABSCO 37202-2 User manual

JABSCO

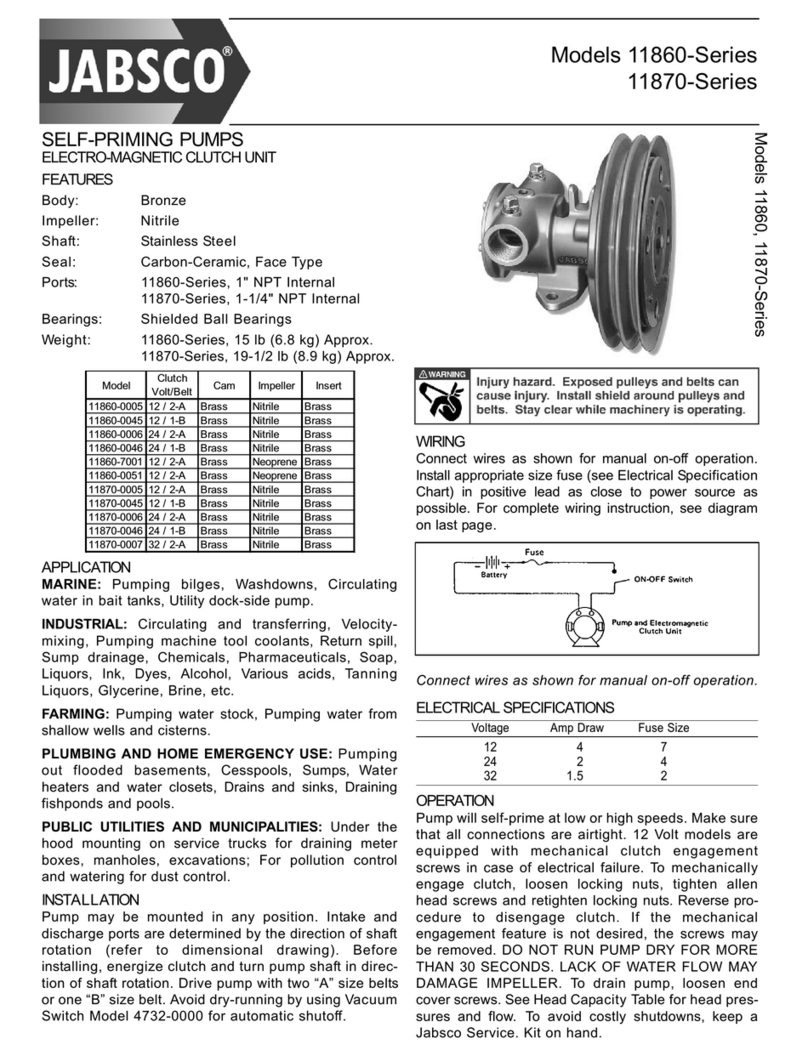

JABSCO 11860-0005 User manual

JABSCO

JABSCO 22060-7125-C User manual

JABSCO

JABSCO 37202-2712 User manual

JABSCO

JABSCO ITT 36600 Series User manual

JABSCO

JABSCO 2620 Series User manual

Popular Water Pump manuals by other brands

DUROMAX

DUROMAX XP WX Series user manual

BRINKMANN PUMPS

BRINKMANN PUMPS SBF550 operating instructions

Franklin Electric

Franklin Electric IPS Installation & operation manual

Xylem

Xylem e-1532 Series instruction manual

Milton Roy

Milton Roy PRIMEROYAL instruction manual

STA-RITE

STA-RITE ST33APP owner's manual