TRU 8 / VideoWin 3 Quick Reference Guide

Page 7of 9

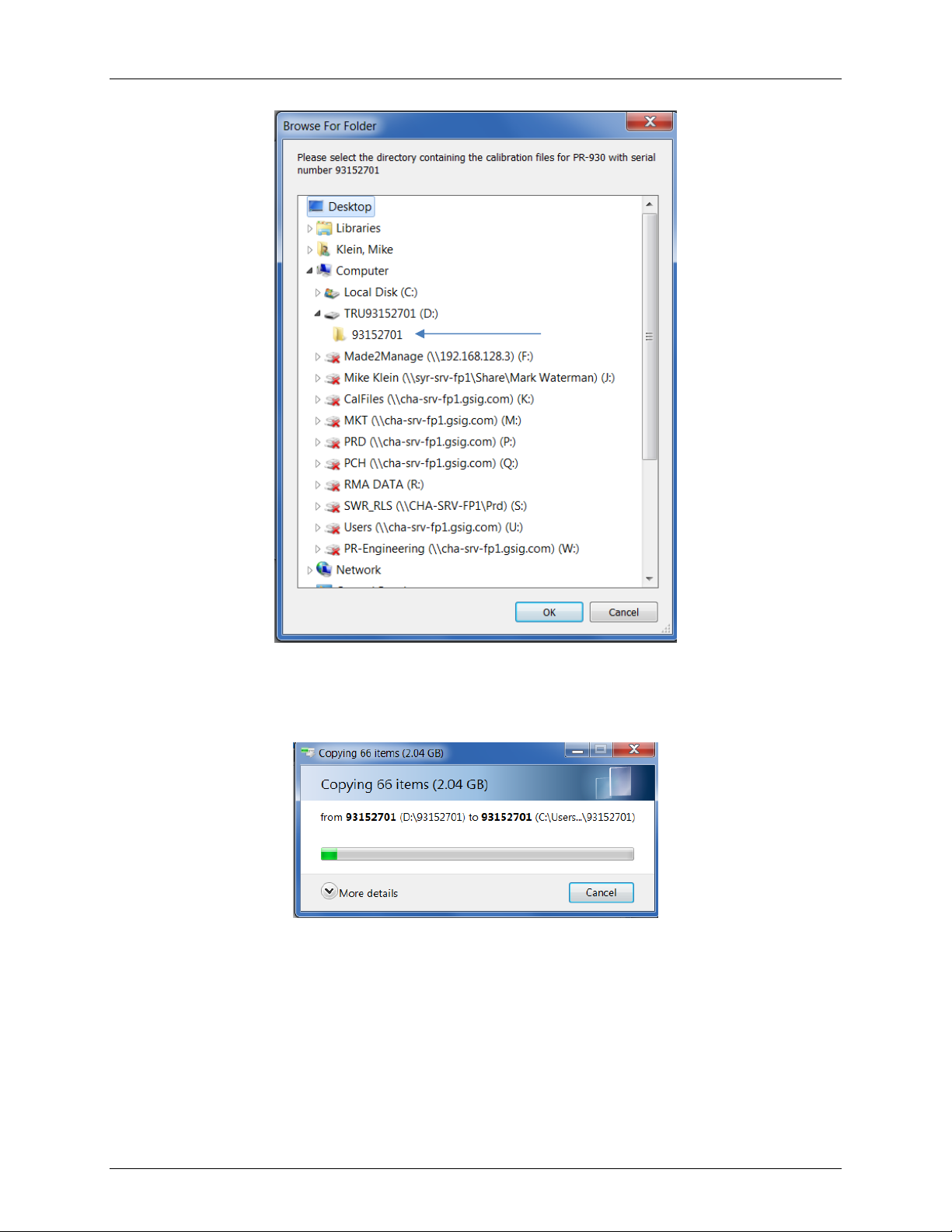

2. Using Windows Explorer, copy the calibration file folder on the flash drive in the TRU8

folder (see above) above to the following location on your hard disk.

C:\Users\Public\VideoWin

Instrument Verification

Perform this test if unexpected uncertainties are experienced when measuring the device under

test (DUT).

Physical Set Up Requirements

Required Equipment

•LRS-4545-6 Calibrated variable luminance and chromaticity standard or equivalent

(Reference Source).

•DUT

•Calibrated spectroradiometer capable of reporting luminance and CIE chromaticity

values with a measuring aperture subtending 2° or smaller.

Minimum Computer Requirements

•Windows based PC

•8 GBytes RAM –more is recommended especially if multiples apps are open

simultaneously

•64 bit Windows 7 or higher

•One available USB 2.0 or higher interface

•Pointing device (mouse)

•CD/DVD player for VideoWin software / calibration files installation

The International Measurements Display Standard (IDMS) should be used as the basis for any

display measurement task. This specification is available from the Society for Information

Display Web site. A brief summary of best practices from the standard are given as follows:

1. Physical distance of LMD (light measurement device) should be no less than 500mm

2. The angular cone of acceptance of the LMD should not exceed 2 degrees.

3. The angular field of view should not exceed 2 degrees.

4. The minimum number of pixels should be no less than 500 pixels or a measurement diameter

greater than 26 pixels for a circular measurement area.

5. Darkroom measurement conditions should be less than 0.01 lux with no obvious reflections or

veiling glare component in the field of measurement.

6. Warm up time should be the greater of 20 minutes or time to reach a fixed measurement of

luminance less than 1%.

7. The following environmental conditions must be obtained:

a. 24°C ±5°C

b. 84 kPa to 106 kPa

c. (25 in Hg –31 in Hg). These are the air pressures for approximately1609 m [5280 ft or

1 mile] down to a little below sea level, for sea level: 101 325 Pa, 76 mm Hg, 29.92 in Hg.

d. 25 % to 85 % RH (non condensing)