109462D

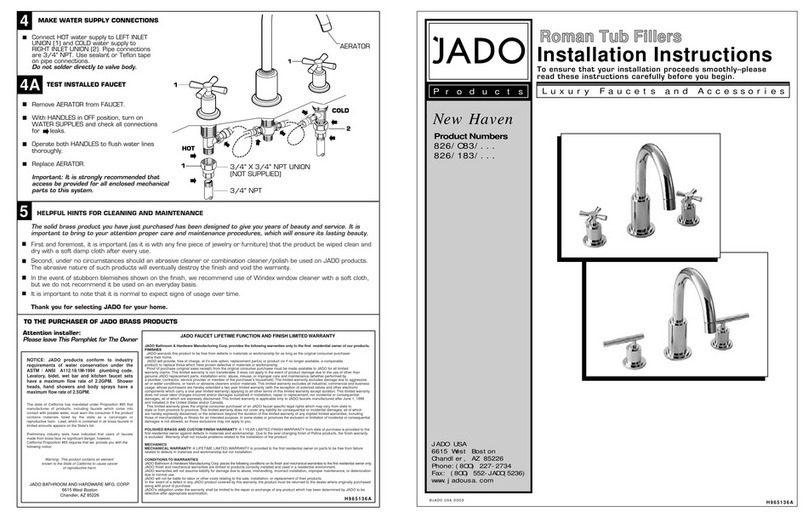

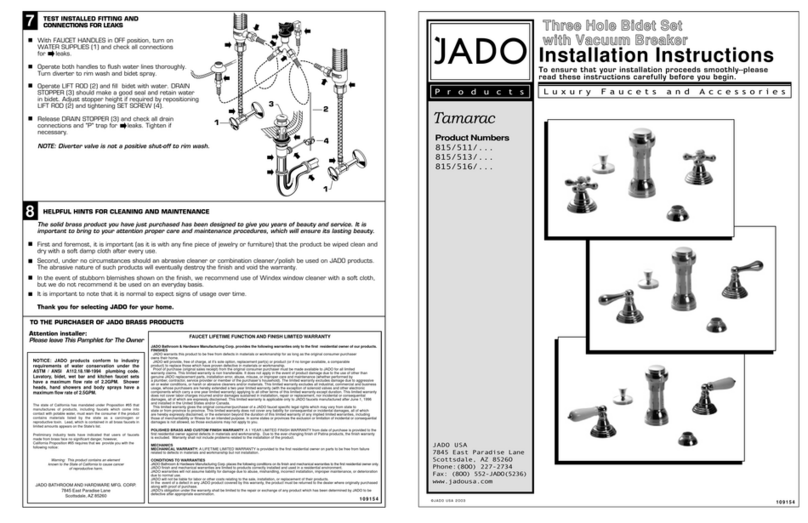

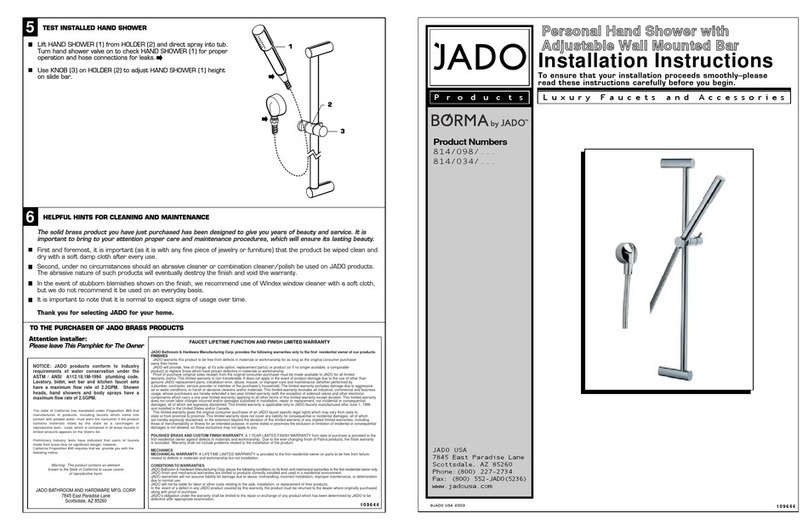

7HELPFUL HINTS FOR CLEANING AND MAINTENANCE

The solid brass product you have just purchased has been designed to give you years of beauty and service. It is

important to bring to your attention proper care and maintenance procedures, which will ensure its lasting beauty.

First and foremost, it is important (as it is with any fine piece of jewelry or furniture) that the product be wiped clean and

dry with a soft damp cloth after every use.

Second, under no circumstances should an abrasive cleaner or combination cleaner/polish be used on JADO products.

The abrasive nature of such products will eventually destroy the finish and void the warranty.

In the event of stubborn blemishes shown on the finish, we recommend use of Windex window cleaner with a soft cloth,

but we do not recommend it be used on an everyday basis.

It is important to note that it is normal to expect signs of usage over time.

Thank you for selecting JADO for your home.

TO THE PURCHASER OF JADO BRASS PRODUCTS

Attention installer:

Please leave This Pamphlet for The Owner

POLISHED BRASS AND CUSTOM FINISH WARRANTY: A 1 YEAR LIMITED FINISH WARRANTY from date of purchase is provided to the

first residential owner against defects in materials and workmanship. Due to the ever-changing finish of Patina products, the finish warranty

is excluded. Warranty shall not include problems related to the installation of the product.

MECHANICS

MECHANICAL WARRANTY: A LIFETIME LIMITED WARRANTY is provided to the first residential owner on parts to be free from failure

related to defects in materials and workmanship but not installation.

CONDITIONS TO WARRANTIES

JADO Bathroom & Hardware Manufacturing Corp. places the following conditions on its finish and mechanical warranties to the first residential owner only.

JADO finish and mechanical warranties are limited to products correctly installed and used in a residential environment.

JADO warranties will not assume liability for damage due to abuse, mishandling, incorrect installation, improper maintenance, or deterioration

due to normal use.

JADO will not be liable for labor or other costs relating to the sale, installation, or replacement of their products.

In the event of a defect in any JADO product covered by this warranty, the product must be returned to the dealer where originally purchased

along with proof of purchase.

JADO's obligation under the warranty shall be limited to the repair or exchange of any product which has been determined by JADO to be

defective after appropriate examination.

The state of California has mandated under Proposition #65 that

manufactures of products, including faucets which come into

contact with potable water, must warn the consumer if the product

contains materials listed by the state as a carcinogen or

reproductive toxin. Lead, which is contained in all brass faucets in

limited amounts appears on the State's list.

Preliminary industry tests have indicated that users of faucets

made from brass face no significant danger, however,

California Proposition #65 requires that we provide you with the

following notice:

NOTICE: JADO products conform to industry

requirements of water conservation under the

ASTM / ANSI A112.18.1-2005 plumbing code.

Lavatory, bidet, wet bar and kitchen faucet sets

have a maximum flow rate of 2.2GPM. Shower

heads, hand showers and body sprays have a

maximum flow rate of 2.5GPM.

Warning: This product contains an element

known to the State of California to cause cancer

of reproductive harm.

JADO warrants this product to be free from defects in materials or workmanship for as long as the original consumer purchaser

owns their home.

JADO will provide, free of charge, at it’s sole option, replacement part(s) or product (or if no longer available, a comparable

product) to replace those which have proven defective in materials or workmanship.

Proof of purchase (original sales receipt) from the original consumer purchaser must be made available to JADO for all limited

warranty claims. This limited warranty is non transferable. It does not apply in the event of product damage due to the use of other than

genuine JADO replacement parts, installation error, abuse, misuse, or improper care and maintenance (whether performed by

a plumber, contractor, service provider or member of the purchaser’s household). The limited warranty excludes damage due to aggressive

air or water conditions, or harsh or abrasive cleaners and/or materials. This limited warranty excludes all industrial, commercial and business

usage, whose purchasers are hereby extended a two year limited warranty (with the exception of solenoid valves and other electronic

components which carry a one year limited warranty) applying to all other terms of this limited warranty except duration. This limited warranty

does not cover labor charges incurred and/or damages sustained in installation, repair or replacement, nor incidental or consequential

damages, all of which are expressly disclaimed. This limited warranty is applicable only to JADO faucets manufactured after June 1, 1996

and installed in the United States and/or Canada.

This limited warranty gives the original consumer purchaser of an JADO faucet specific legal rights which may vary from state to

state or from province to province. This limited warranty does not cover any liability for consequential or incidental damages, all of which

are hereby expressly disclaimed, or the extension beyond the duration of this limited warranty of any implied limited warranties, including

those of merchantability or fitness for an intended purpose. In some states or provinces the exclusion or limitation of incidental or consequential

damages is not allowed, so those exclusions may not apply to you.

JADO Bathroom & Hardware Manufacturing Corp. provides the following warranties only to the first residential owner of our products.

FINISHES

JADO FAUCET LIFETIME FUNCTION AND FINISH LIMITED WARRANTY

6

Remove Handle and Trim from Valve. See step 1 for reference.

Shut off water supply by either closing off main water supply, or closing off the hot and cold CHECK STOPS on valve, if present.

TO GAIN ACCESS TO VALVE FOR SERVICING

Remove CARTRIDGE (1) by removing CARTRIDGE SCREWS (2). Remove three SCREWS (3) from FIXATION RING (4) and

pull out PRESSURE BALANCING (5) unit.

Clean SEALS (9) on base of CARTRIDGE (1). Check base of PRESSURE BALANCING UNIT (5) and clean O-RINGS (6).

Remove CAPS (7) and check O-RINGS on inside of CAPS (7). Clean inside sealing surfaces of VALVE BODY (8).

Re-assemble PRESSURE BALANCING UNIT (5) and CARTRIDGE (1). Tighten all screws. Turn on water supply and see

above for installing TRIM and HANDLE.

VALVE LEAKS WHEN SHUT OFF

BACK TO BACK INSTALLATION

ROTATE 180˚

Remove PRESSURE BALANCE UNIT (5). Remove CAPS (7) and clean valve thoroughly.

Examine balancing unit and check condition of O-ring on end of piston. Piston should move back and forth. Order Repair

Part M952100-0070 if balancing unit is defective.

Replace CAPS (7) and install PRESSURE BALANCE UNIT (5). Make sure inlets line up with two holes in bottom of casting.

Top flange should butt-up against top of casting.

UNABLE TO MAINTAIN CONSTANT TEMPERATURE

1

2

9

5

5

7

8

6

4

3

INLETS

LARGE OUTLET

JADO BATHROOM AND HARDWARE MFG. CORP.

8404 Killam Blvd.

Laredo TX, 78045