Fitting Guide for

Ensure that rod end has a 15°-20° lead-in.

Align the rod carefully, and insert it until it

just touches the seal, then press the rod

®

firmly through the seal bore. The Teesele

is now installed.

Align rod and firmly press through

seal bore.

GB

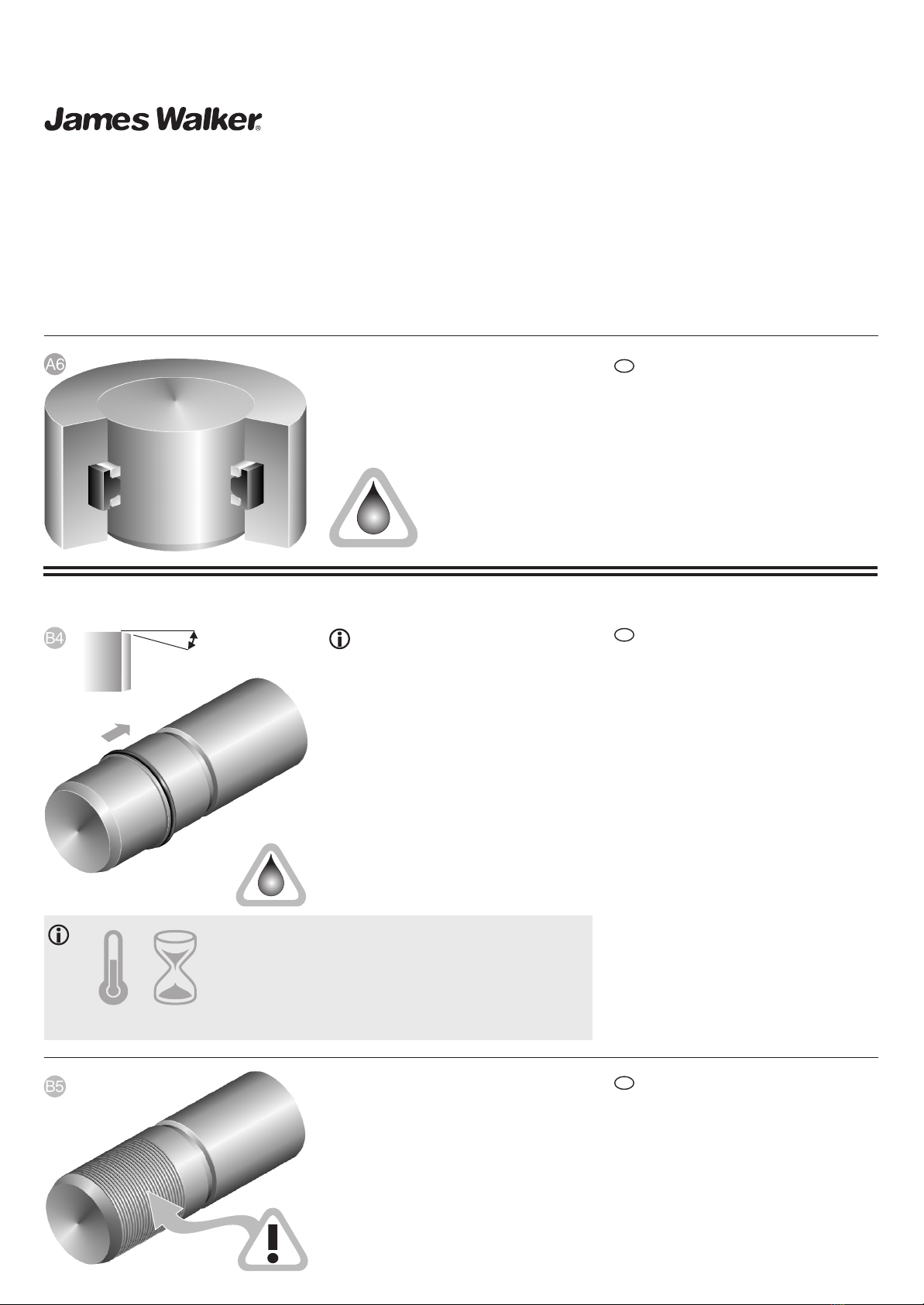

B: External seal applications

Ensure there is a 15°- 20° lead-on

at the end of the rod.

15°- 20°

Stretch the elastomeric sealing element

over the rod, using the 15°-20° lead-on to

aid stretching. It is advisable to stretch

the seal ID to a size greater than the

cylinder bore. Push the elastomeric

element along the rod until it locates in the

housing groove correctly.

Note: the elastomer may need time to seat

in the groove, depending upon the

environmental temperature.

A thin film of system compatible lubricant

may be used (if in doubt, please contact

James Walker or the equipment

manufacturer).

not

If elastomeric sealing element cannot be stretched

sufficiently, then warm it for about 30 minutes at 100°C

in a conventional oven. Once warmed, follow the fitting

guide instructions shown above. Follow local Health &

Safety regulations for handling of hot items.

Allow elastomeric element to return to ambient

temperature, then check that it is seated properly.

Stretch elastomeric element on to

rod and push to housing groove

GB

GB Cover threaded/abrasive areas

before pushing sealing element

over them

A thin film of system compatible

lubricant may be used (if in

doubt, please contact James

Walker or the equipment

manufacturer).

100°C 30 mins

When the elastomeric sealing element

must pass over a threaded or abrasive

surface, cover the rod surface to protect

the seal. When passing over grooves,

these should be filled to allow smooth

transit of seal components.

®

Teesele — double-acting dynamic seal for high pressure equipment