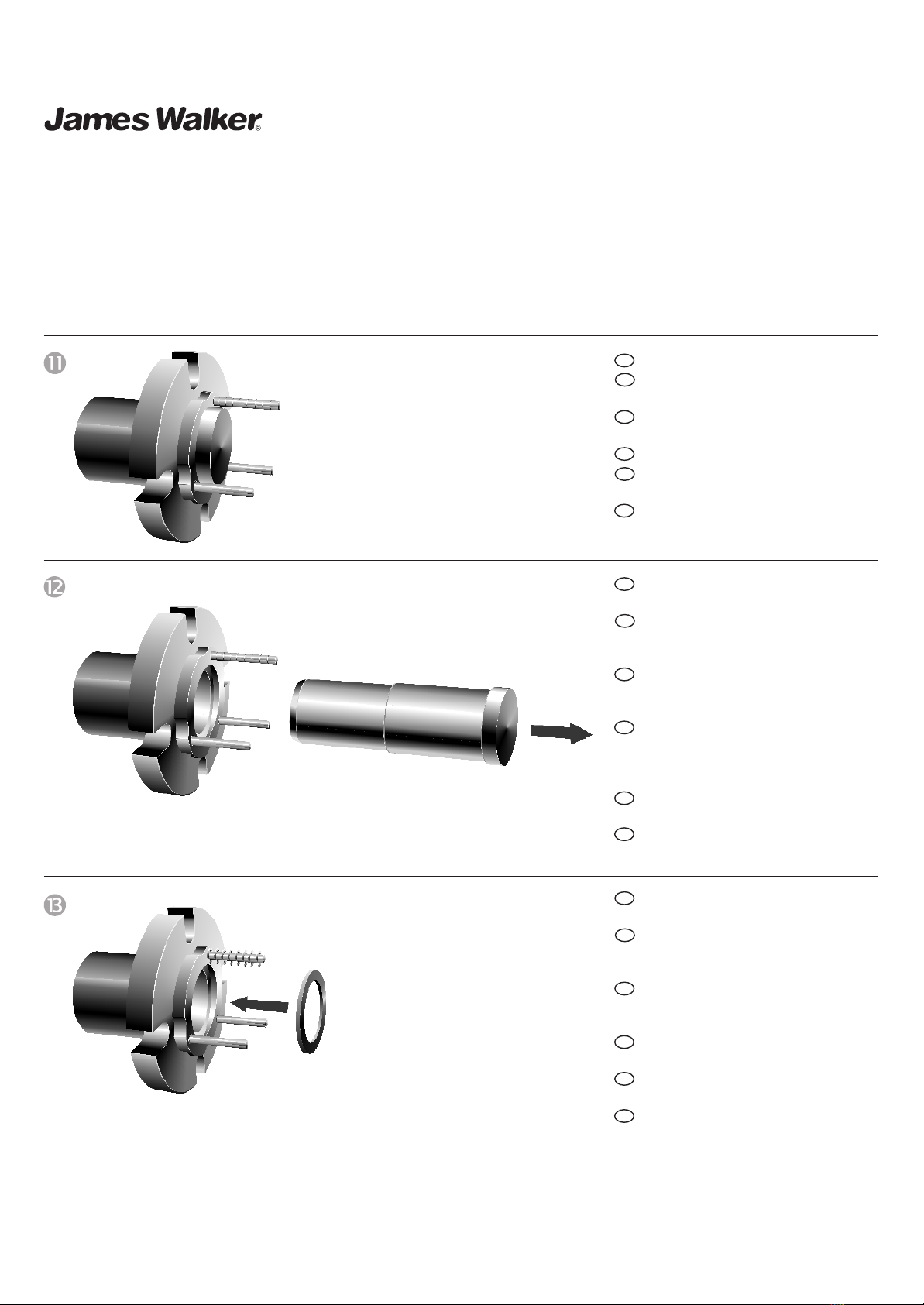

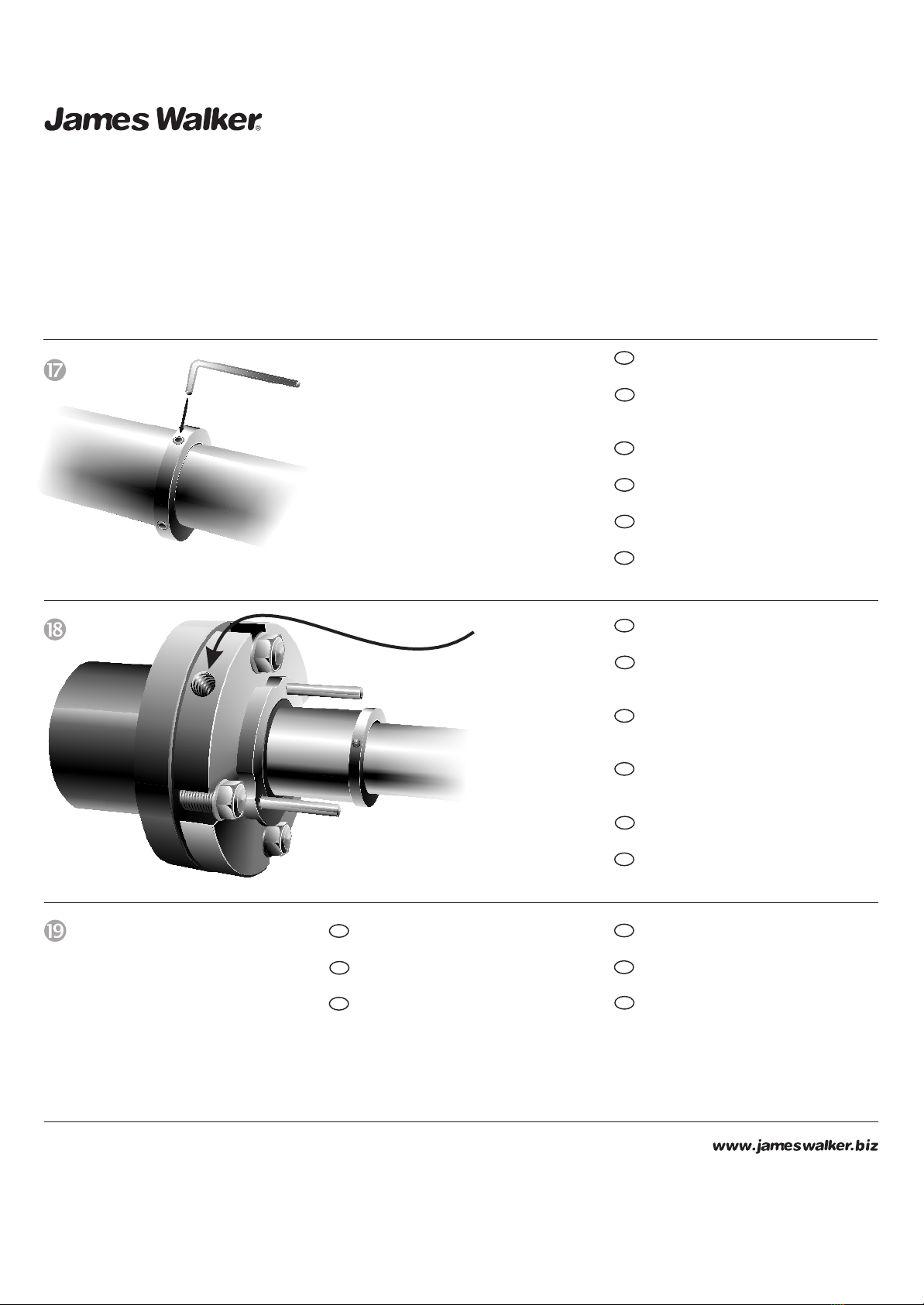

Tighten Set Screws to affix Shaft

Sleeve to shaft.

Serrare la serie di viti per fissare il

manicotto all'albero.

Draai de Set Screws vast om zo de

asbus op de as te bevestigen.

Apretar los tornillos de fijación

para fijar el casquillo del eje al eje.

Serrer l'ensemble des vis pour fixer

la douille à l'arbre ;

Ziehen Sie die Schrauben an, um

die Wellenschutzhülse auf der

Welle anzubringen.

If needed, reconnect flush system.

Start flush.

Ricollegare, se necessario, il

sistema di flussaggio. Avviare il

flussaggio.

Indien nodig, sluit de spoelleiding

weer aan. Activeer het

spoelsysteem.

Si es necesario, volver a conectar

el flujo. Poner en marcha el flujo.

Si besoin, reconnecter le circuit de

flush; mettre en pression le circuit.

Falls nötig, klemmen Sie das

Spülungs-System um. Starten Sie

die Spülung.

At pump start-up vent air from

chamber.

All'avviamento della pompa far

sfogare l'aria dalla camera.

Lüften Sie die Luft aus der Kammer

beim Start-up der Pumpe.

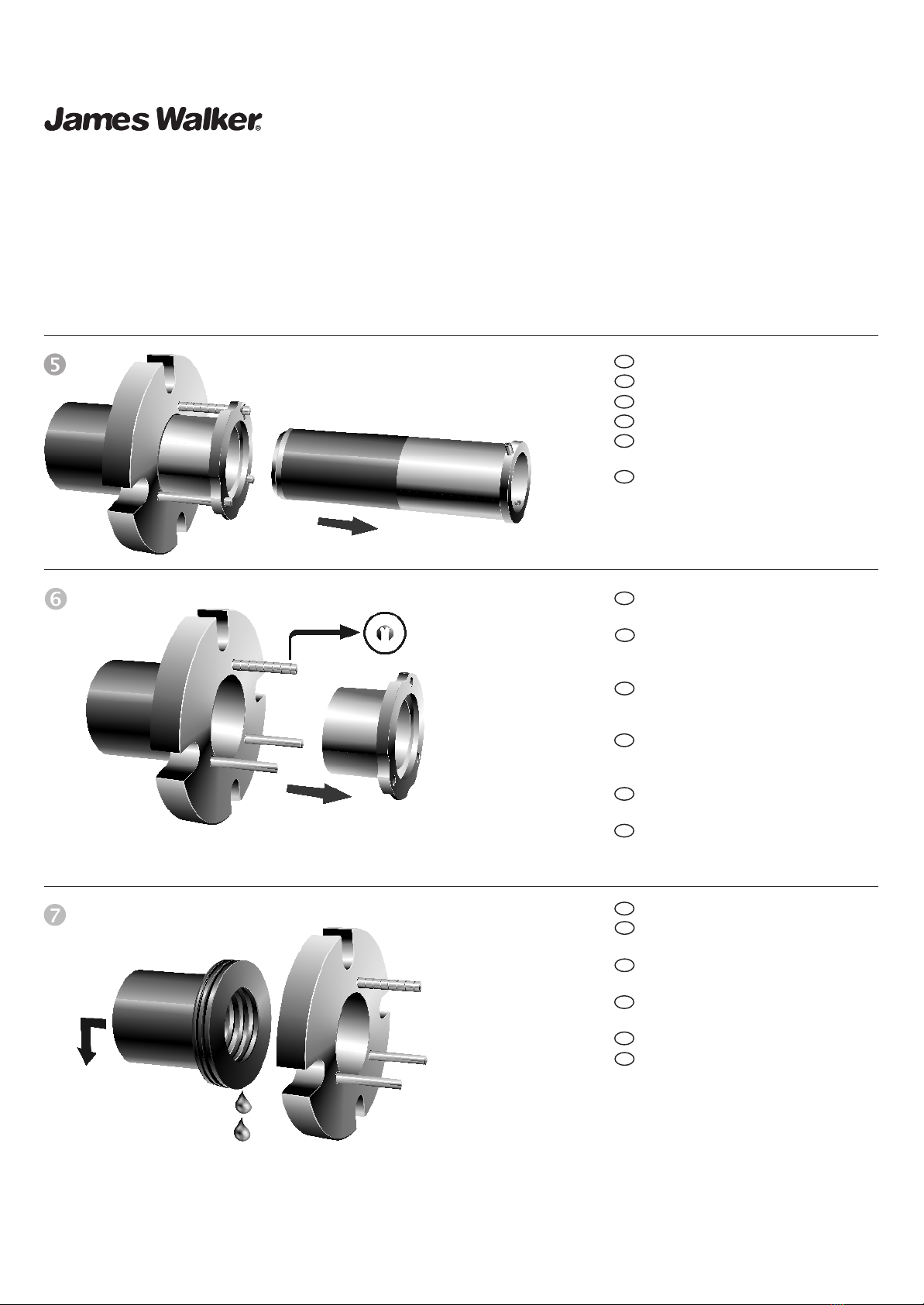

Affix the Shaft Sleeve to pump shaft by

evenly tightening each set screw until it

just touches the shaft. Then tighten set

screws until the points are embedded in

shaft surface.

Where necessary,

re-connect the

flush system and

apply flush water

to cartridge before

pump start-up.

Pump is now

ready to enter

service with the

new Sealing

Element

CPC 08 Level 08 T03 180611

James Walker & Co Ltd Customer Support Centre, 1 Millennium Gate, Westmere Drive, Crewe, Cheshire, CW1 6AY, UK

Material Safety Data Sheets are available on request

Health warning: If PTFE or fluoroelastomer (eg, FKM, FFKM, FEPM) products are heated to elevated temperatures, fumes will be produced which may give unpleasant effects, if inhaled. Whilst some

fumes are emitted below 250°C from fluoroelastomers or below 300°C from PTFE, the effect at these temperatures is negligible. Care should be taken to avoid contaminating tobacco with particles of

PTFE or fluoroelastomer, or with PTFE dispersion, which may remain on hands or clothing.

Information in this publication and otherwise supplied to users is based on our general experience and is given in good faith, but because of factors which are outside our knowledge and control and affect

the use of products, no warranty is given or is to be implied with respect to such information. Unless governed by type approval or contract, specifications are subject to change without notice. Statements

of operating limits quoted in this publication are not an indication that these values can be applied simultaneously.

To ensure you are working with the very latest product specifications, please consult the relevant section of the James Walker website: www.jameswalker.biz.

At start-up, open all valves to flood

the pump chamber. If possible, vent

any air that may be trapped in

chamber.

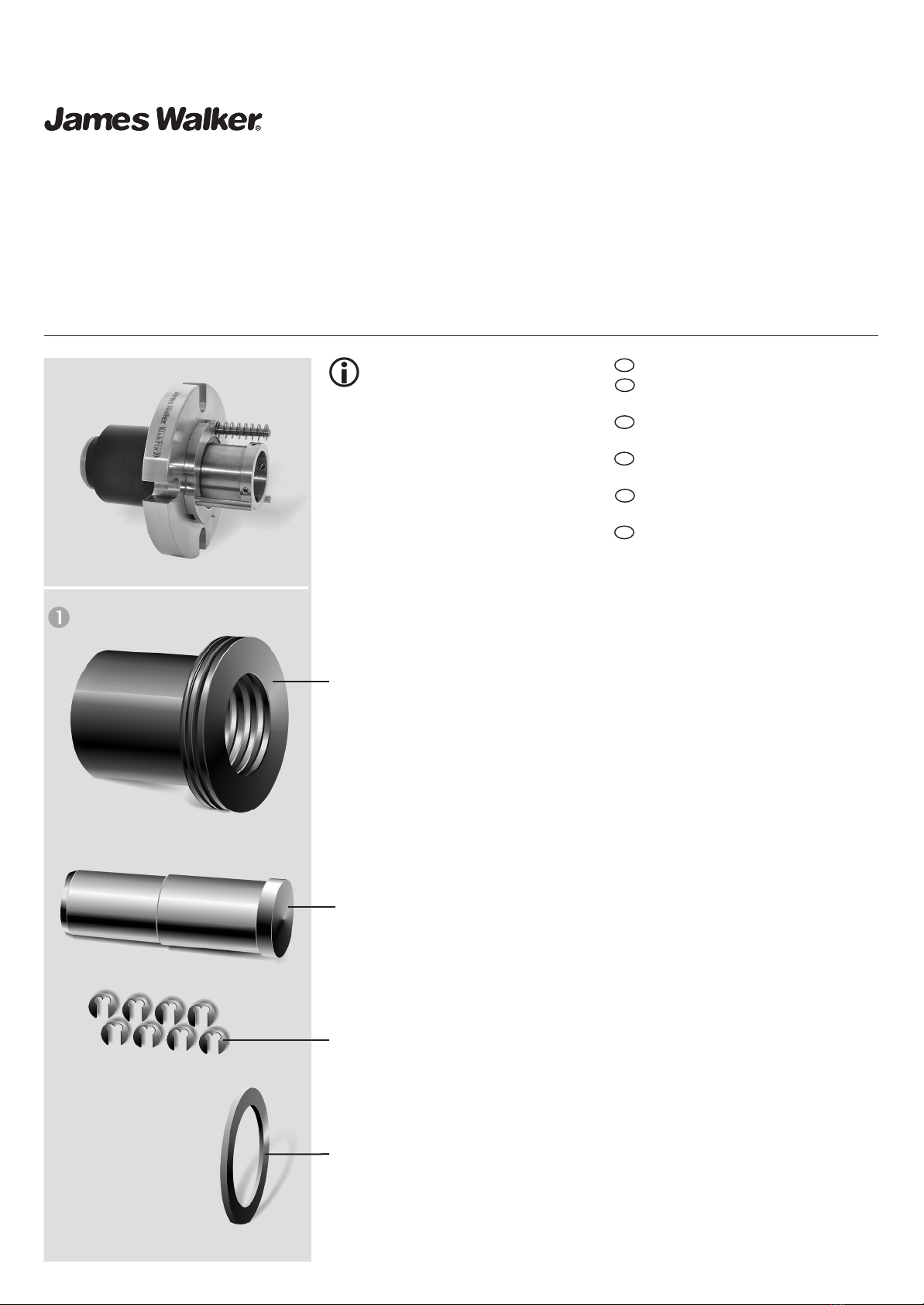

James Walker KlickFix®

On-site Refurbishment Guide for

EN

DE

IT

NL

ES

EN

DE

IT

NL

ES

EN

DE

IT

NL

ES

F

F

F

Ontlucht bij het opstarten van de

pomp de sealkamer.

Al arrancar la bomba purgue el aire

de la cámara.

Au démarrage de la pompe, laisser

échapper l'air de la chambre.