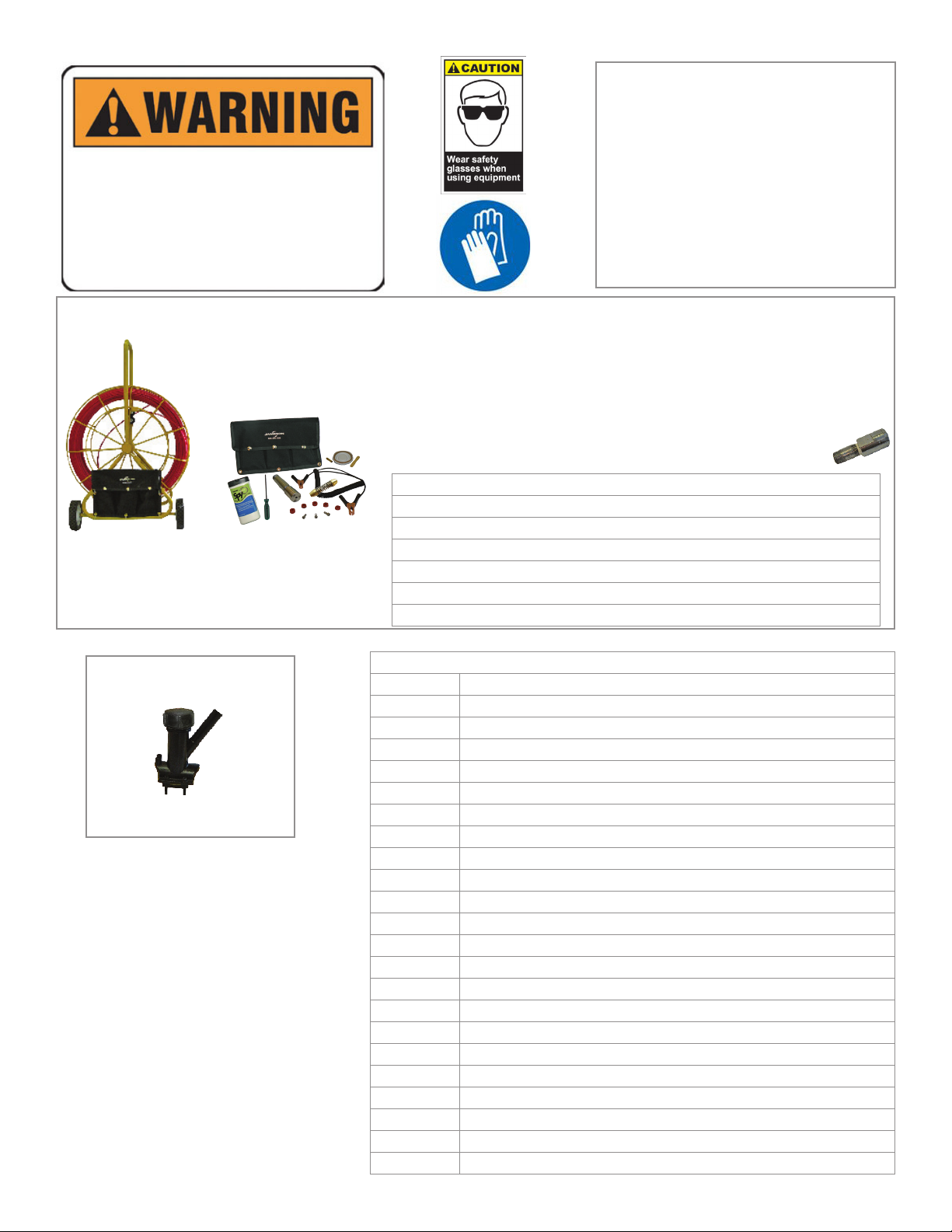

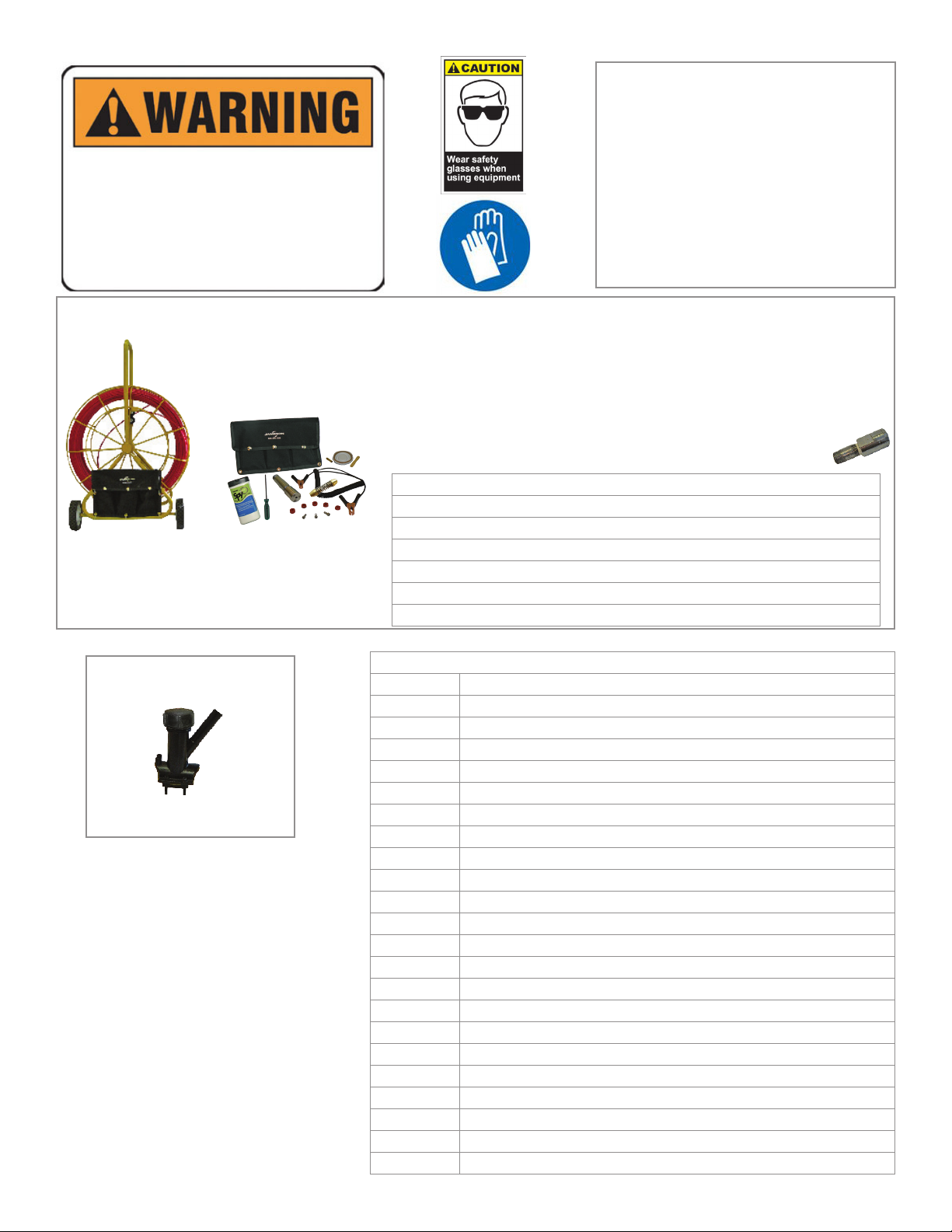

Traceable Fiberglass Rodder - Unit has 1/4” diameter rod with permanent

5/16” diameter end ferrule, Rod has copper trace wire embedded in berglass

core and is coated with polypropylene jacket for safety and durability.

Accessory Kit - Canvas Storage Bag, Grounding Cable, 3 Screws,

11 O-Rings, Rod Lubricant, Hex Key Driver, Adhesive, Replacement

End Ferrule, Spring Leader

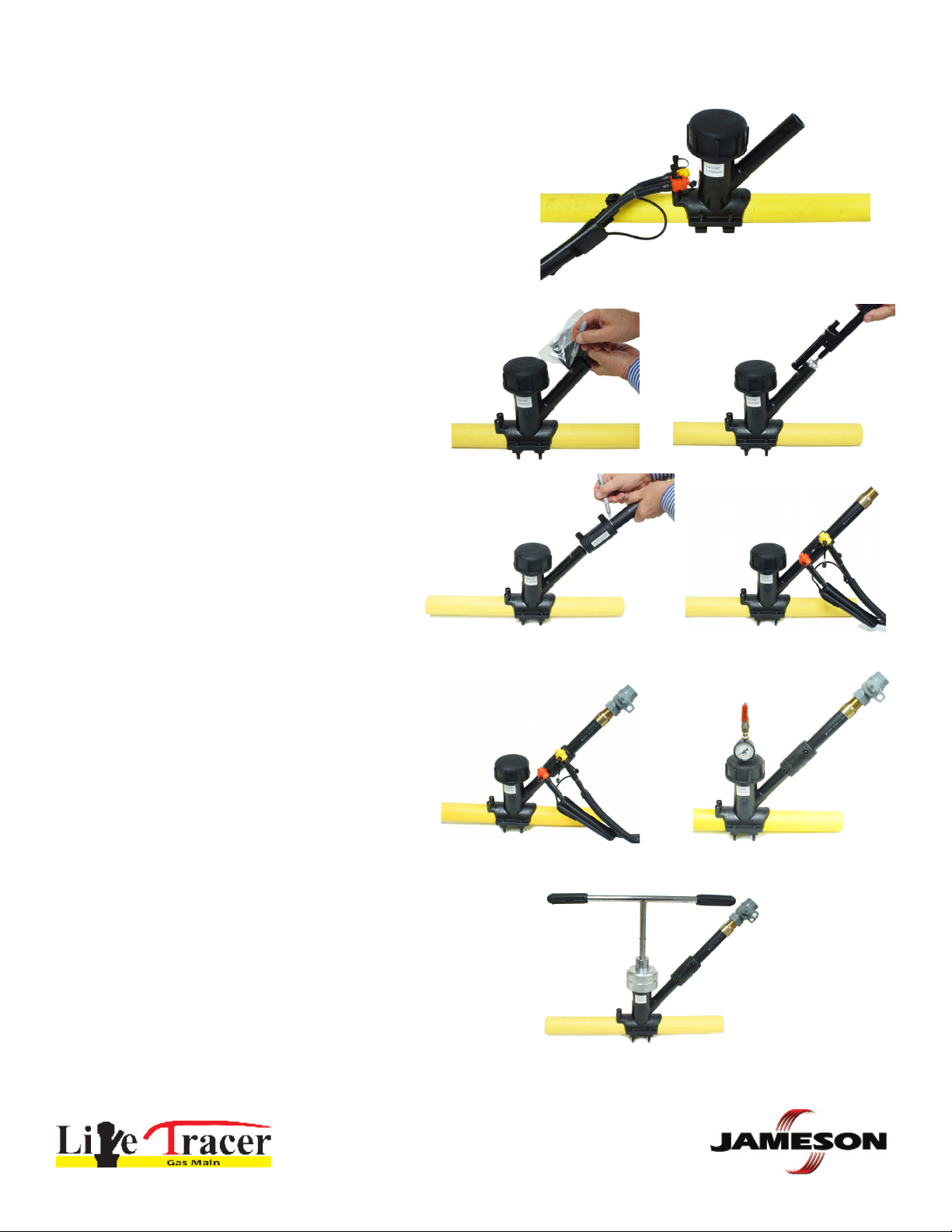

Stufng Box - Designed with custom o-ring to provide seal when

rod is inserted into pressurized lines for use up to 100 psi. Includes

4” pipe nipple with 1” NPT thread.

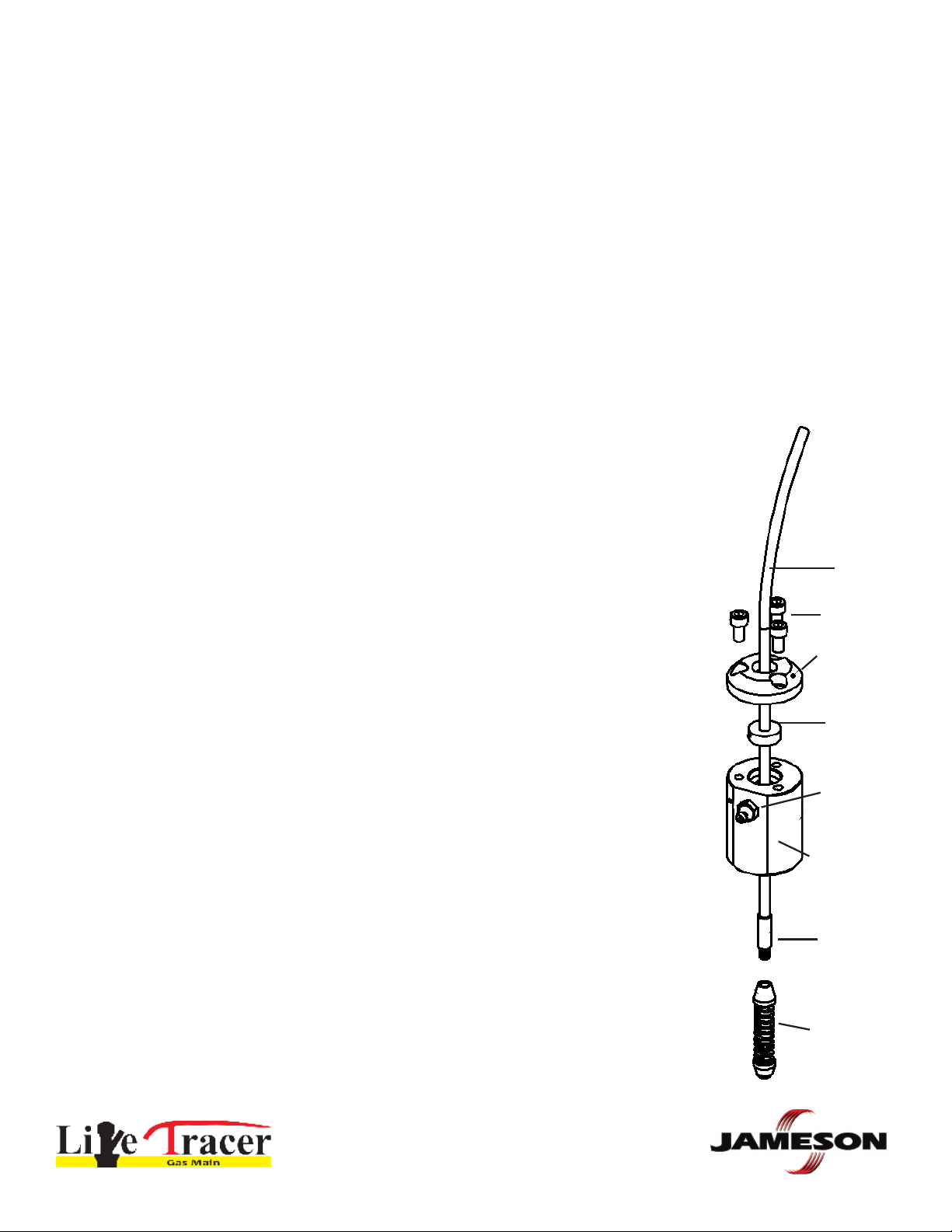

NOTICE

The components of the Live Tracer system are

specically designed to work exclusively with

each other.

The use of these components individually or in

combination with other non-Jameson tools or

accessories is not recommended and will not

guarantee the safety or effectiveness of the

system.

Required tools not included in this kit:

Gas leak detector / soap solution

Transmitter and Receiver for locating

Wrenches, channel locks

Various pipe ttings (may be required to adapt 1” NPT to your specic tting)

Teon tape / pipe dope

Grease gun with 1/4” button tting

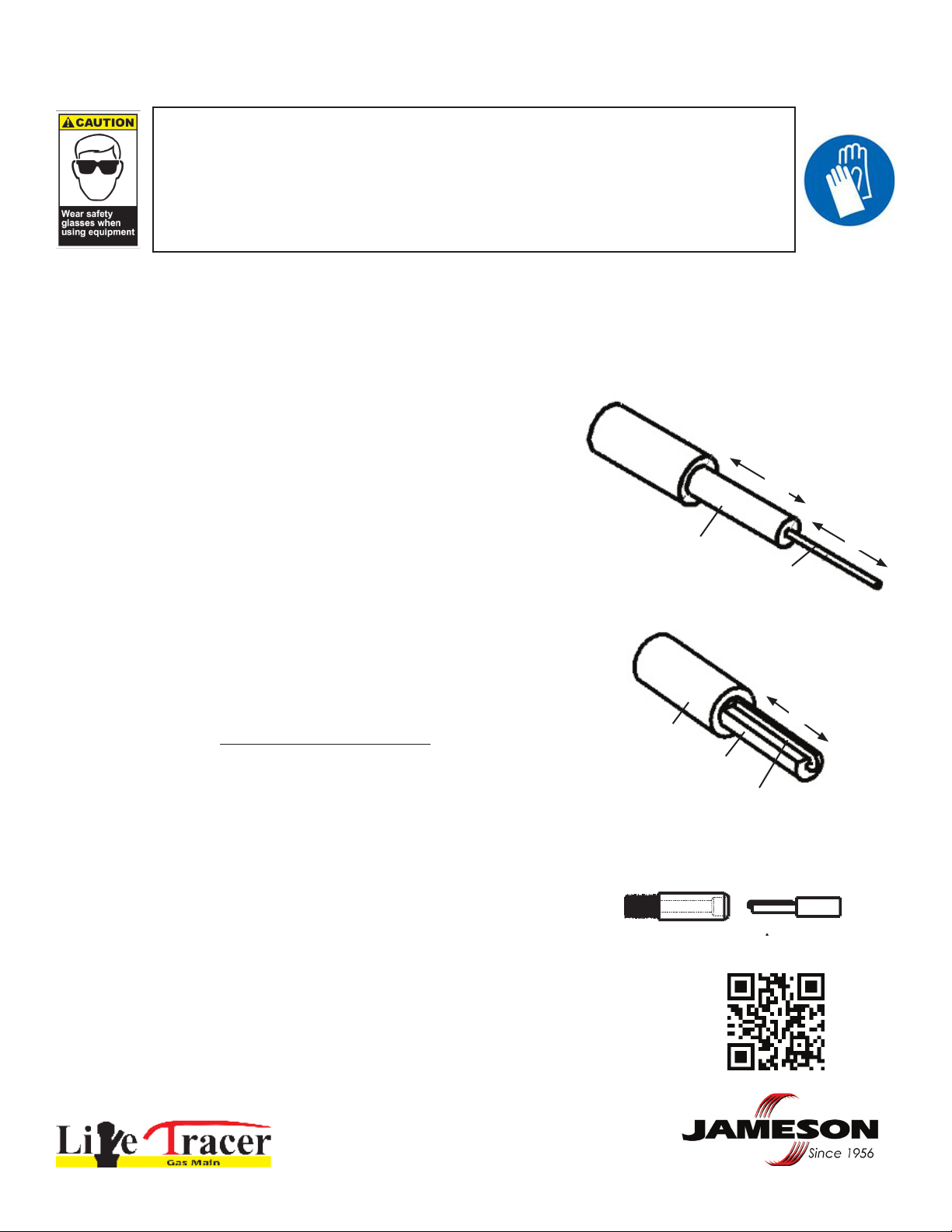

Read and understand these operating and safety

instructions before using or servicing this equip-

ment.

Failure to follow instructions could result in an

accident causing serious injury. Do not allow chil-

dren or untrained personnel to use this equipment.

Follow your company installation procedures.

Specic parts and accessories

may vary according to your

company procedures.

Part Number

16-14-600-GL

Sold Separately

Electrofusion Insertion

Tapping Tee

Live Tracer Kit

Live Tracer Accessories - Sold Separately

16-2-TEE Electrofusion Tapping Tee for 2” Gas Main (4.7 mm resistor terminals)

15-WIPE Lubricating Wipes - Feeding Rod into Stufng Box

16-AWIPE Large Alcohol Wipes, 60 ct. - Clean Pipe for Electrofusion

16-169 Spring Leader

16-168 Flexible Sonde Adapter - Attaches Sonde to Rod

16-170 O-Ring Replacements, 10 ct.

16-SB Stufng Box, Three Screws, Six O-Rings

16-HVTAP HV Tap Tool

16-CW HVTT Cap Wrench

16-EFC-1 1” IPS Electrofusion Coupling (4.7 mm resistor terminals)

16-1HSCR Hand Scraper - Prepare Pipe for Electrofusion

16-RSCR 2” IPS Rotary Scraper - Prepare Pipe for Electrofusion

16-1PSCR 1” Poly Peeler - Prepare 1” Pipe (PUP)

16-TC HVTT Test Cap

16-TCG HVTT Test Cap with Gauge

16-HVTTR HVTT Tool Ratchet Handle

16-PROC Processor

16-PUP-12 PUP Extension Valve Assembly (12” Lead)

16-FLEX Flex Riser Valve Assembly

16-146 End Ferrule Replacement Kit

16-B7105 1” X 24” IPS, PE4710 Bronze Male Thread Transition

16-B7110 1” X 24” CTS, PE4710 Bronze Male Thread Transition

16-45ELB 45º Elbow, 1” IPS