2

ImportantSafetyPrecautions

When installing and using this electrical equipment, these basic safety precautions should always be

followed:

1. READ AND FOLLOW ALL INSTRUCTIONS.

2.DANGER- to reduce the risk of injury, do not permit children to use this product unless they are closely

supervised at all times.

3. All electrical work must be performed by a licensed electrician and must conform to all national, state, and local

codes.

4. WARNING: Water temperature in excess of 100°F/38°C may be injurious to your health.

AVERTISSEMENT: Il peut être dangereux pour la santéde se plonger dans de l'eau àplus de 100°F/38°C.

Prolonged immersion in hot water may induce hyperthermia. Hyperthermia occurs when the internal

temperature of the body reaches a level several degrees above the normal body temperature of 98.6°F/37°C.The

symptoms of hyperthermia include dizziness, fainting, drowsiness, lethargy, and an increase in the internal

temperature of the body. The effects of hyperthermia include: 1) unawareness of impending danger; 2) failure to

perceive heat; 3) failure to recognize the need to exit spa; 4) physical inability to exit spa; 5) fetal damage in pregnant

women; 6) unconsciousness resulting in a danger of drowning. WARNING - The use of alcohol, drugs, or

medication can greatly increase the risk of fatal hyperthermia in hot tubs and spas.

La consommation d'alcool ou

de drogue augmente considérablement les risques d'hyperthermie mortelle dans une cuve de relaxation.

5. Install to provide drainage of compartment for electrical components.

6. Install at least five (5) feet (152.4cm) from the inside wall of the pool and tub. Canadian installations must be at least

three (3) meters from the water.

Les installations canadiennes doivent se trouver àau moins trois (3) mètres de l'eau.

7. A ground-fault circuit-interrupter must be provided if this device is used to control underwater lighting fixtures. The

conductors on the load side of the ground-fault circuit-interrupter shall not occupy conduit, boxes or enclosures

containing other conductors unless the additional conductors are also protected by a ground-fault circuit-interrupter.

Refer to local codes for complete details.

8. A terminal bar marked GROUND is provided within the Power Center. To reduce the risk of electrical shock, connect

this terminal bar to the grounding terminal of your electric service or supply panel with a continuous green insulated

copper wire equivalent in size to the circuit conductors supplying this equipment, but no smaller than No. 12 AWG

(3.3 mm). In addition, a second wire connector should be bonded with a No. 8 AWG (4.115mm) copper wire to any

metal ladders, water pipes, or other metal within 5 feet (1.52m) of the tub.

9.CONTROL SYSTEM IS INTENDED TO CONTROL HEATERS WITH BUILT-IN HIGH LIMIT CIRCUITS ONLY.

10.PLEASE SAVE THESE INSTRUCTIONS.

LIRELANOTICETECHNIQUE.

SPECIFICATIONS(USA&CANADA):

POWER SUPPLY: 120 Volts A.C.; 60 Hz.; 3 amps.

CONTACT RATING:(High Volt.) 25 amp; 3 h.p. @ 240 Volts A.C.,

1½h.p. @ 120 Volts A.C.;

1500 Watts Incandescent

CONTACT RATING: (Low Volt.) Class Two, 1 amp at 24V A.C.

EMERGENCY SERVICE SWITCHES: All circuits.

DIMENSIONS(USA&CANADA):

Standard Power Center: Height-13¾"; Width-14½"; Depth-5"

Sub Panel Power Center: Height-20"; Width-14½"; Depth-5"

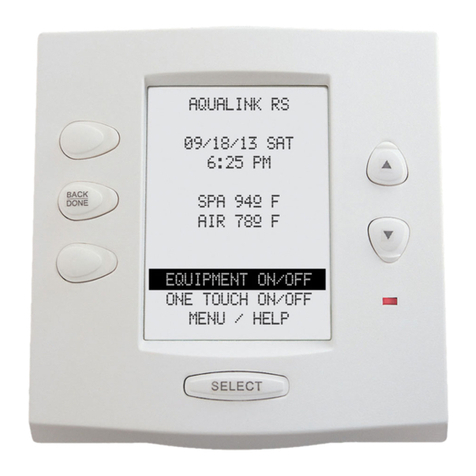

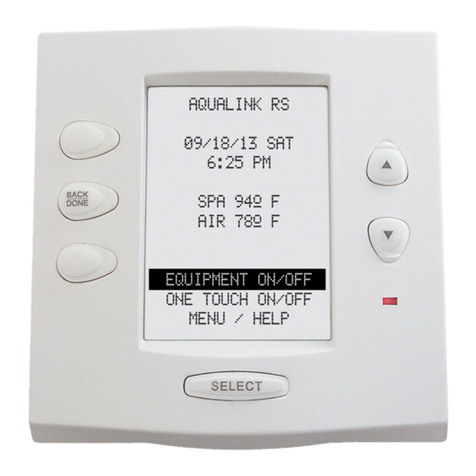

All Button Control Panel: Length-8"; Width-5"; Depth-1¼"

OneTouch Control Panel Height-4½"; Width-4½"; Depth-1¼"

Four Function Switch: Diameter-2¾"

SPECIFICATIONS(EUROPEAN):

POWER SUPPLY: 230-240V~50/60 Hz.; 3 A.

CONTACT RATING:(High Volt.) 25A;3h.p.@240Volts V~

CONTACT RATING: (Low Volt.) Class Two@24V~

EMERGENCY SERVICE SWITCHES: All circuits.

DIMENSIONS(EUROPEAN):

Standard Power Center: Height-35.3cm; Width-37.2cm; Depth-12.8cm

Sub Panel Power Center: Height-51.3cm; Width-37.2cm; Depth-12.8cm

All Button Control Panel: Length-20.5cm; Width-12.8cm; Depth-3.2cm

OneTouch Control Panel Height-11.43cm; Width-11.43cm; Depth-3 cm

Four Function Switch: Diameter-7.1cm