© BA_DKV_EN_Rev07-2010.DOC Page 4 von 20

2.1.1 Sealing Ring

Silicone rubber (VMQ)

Particularly suitable for the foodstuffs area.

Resistant to many chemicals; not suitable for oils, fuels, hot vapors, aromatics, chlorinated solvents,

esters, ketones, concentrated acids and bases.

For temperatures from -60° C to +200 C.

Nitrile rubber (NBR black)

Particularly suitable for bulk materials, oils, fats, fuels, alphatic solvents, steam.

Not suitable for aromatic hydrocarbons (toluene, xylene), chlorinated hydrocarbons (Tri, Per), ketones,

esters, ethers.

For temperatures from -30° C to +120° C.

Other sealing-ring materials are available on request.

2.1.2 Sealing plate

Mild steel (St 37), painted,

for normal conditions of use

Stainless steel (1.4301 or 1.4571)

for use with aggressive media and in the foodstuffs area.

2.2 Transport and Storage

no pressure on the sealing element.

Storage temperature +12° C to +20° C, relative humidity approx. 65 %.

Protect seals against direct sunlight.

3 Operation and Installation

3.1 Operation

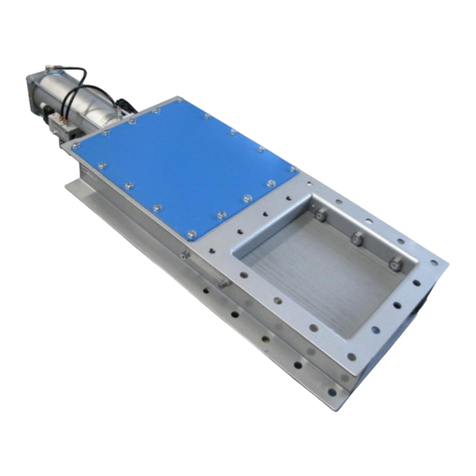

JAUDT Vario butterfly valves can be supplied as desired with the following methods of operation:

Hand-operated lever

Pneumatic cylinder

Pneumatic rotating actuator (PDA)

Electric servo drive

Special equipment hydraulic cylinder

Attention: Limit the activation pressure on 40 bar, in order to avoid damages of the equipment

on blocking the sealing plate.

No particular instructions need to be observed for operation. The position of the flap is indicared by the

notch on the end of the shaft.

Models with the hand-operated lever are provided with additional markings at 15°-intervals:

0 -

90 -pos

Respect with loosely provides hand operation to the correct installation of pointer, wearing part (between

console and hand lever at the screw of the gripping washer) , hand lever an gripping washer.