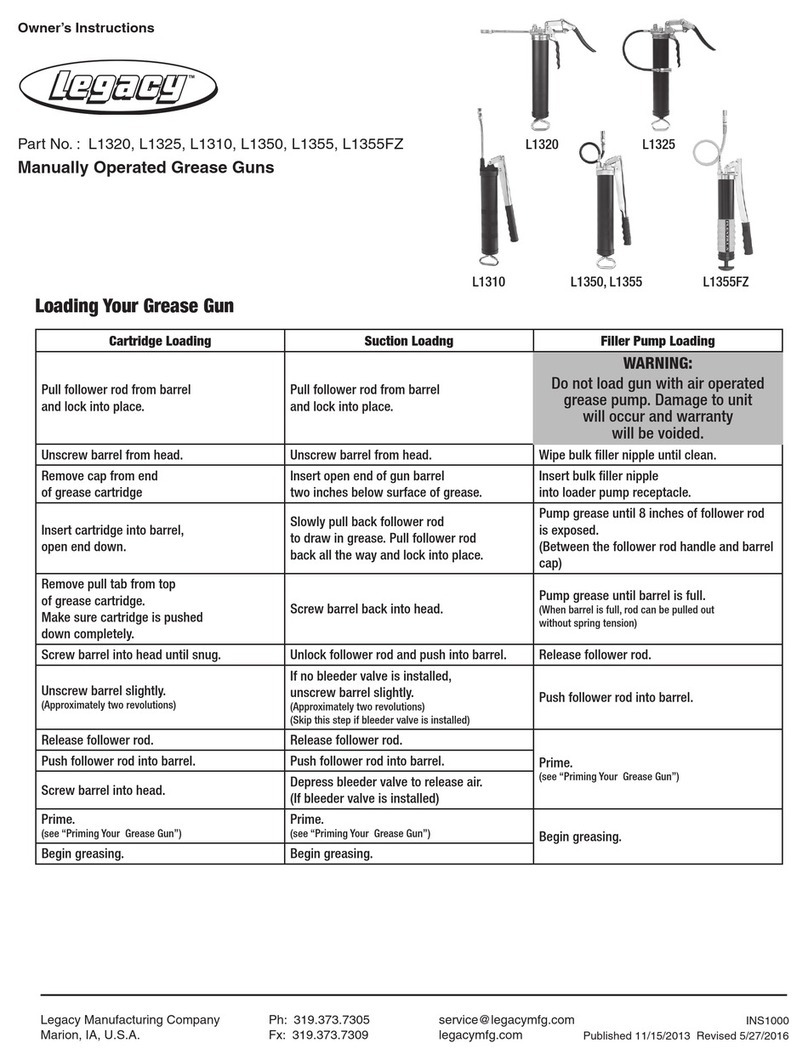

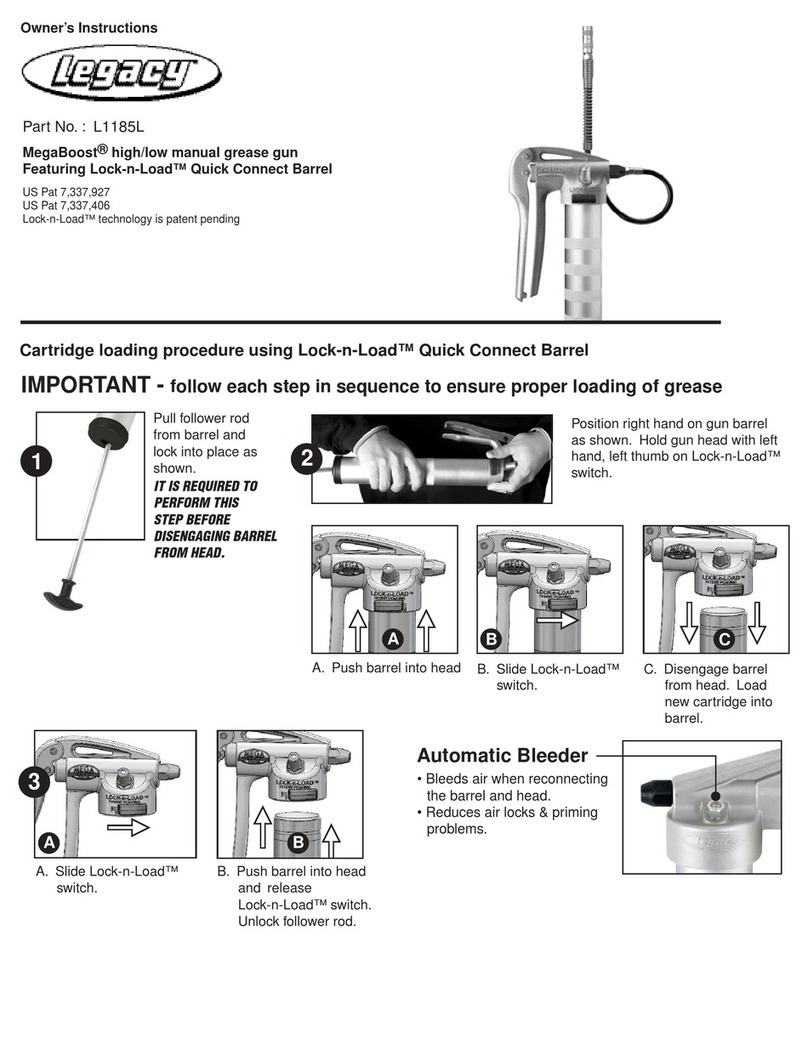

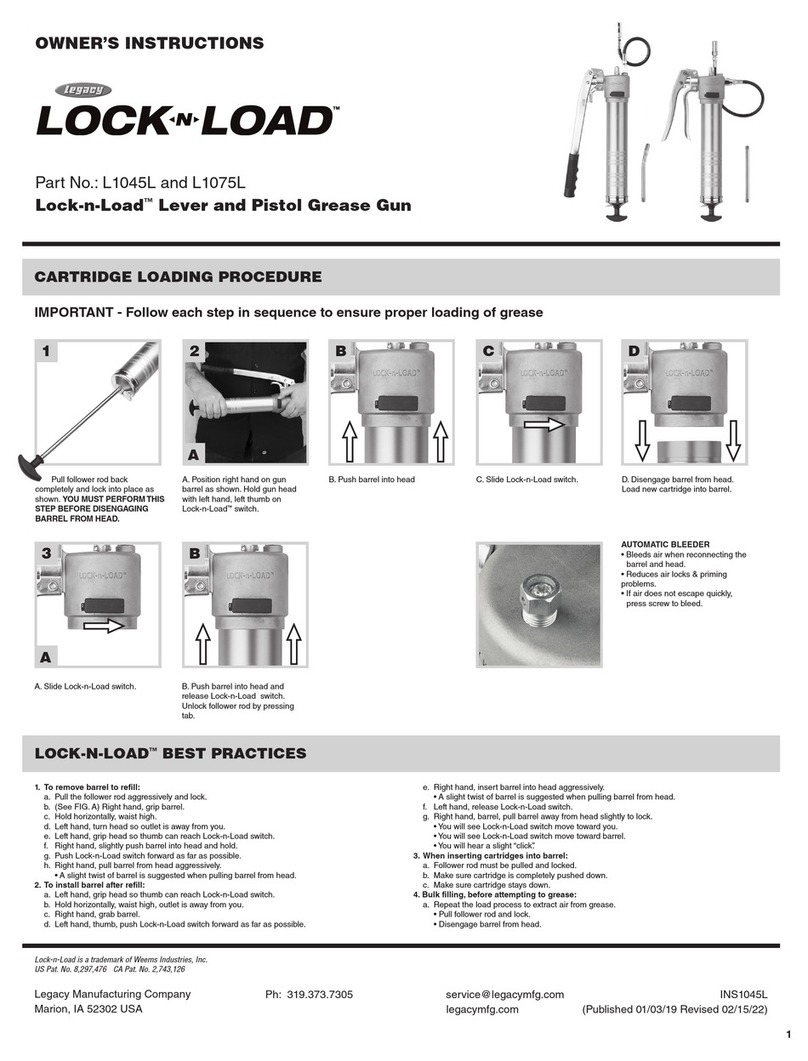

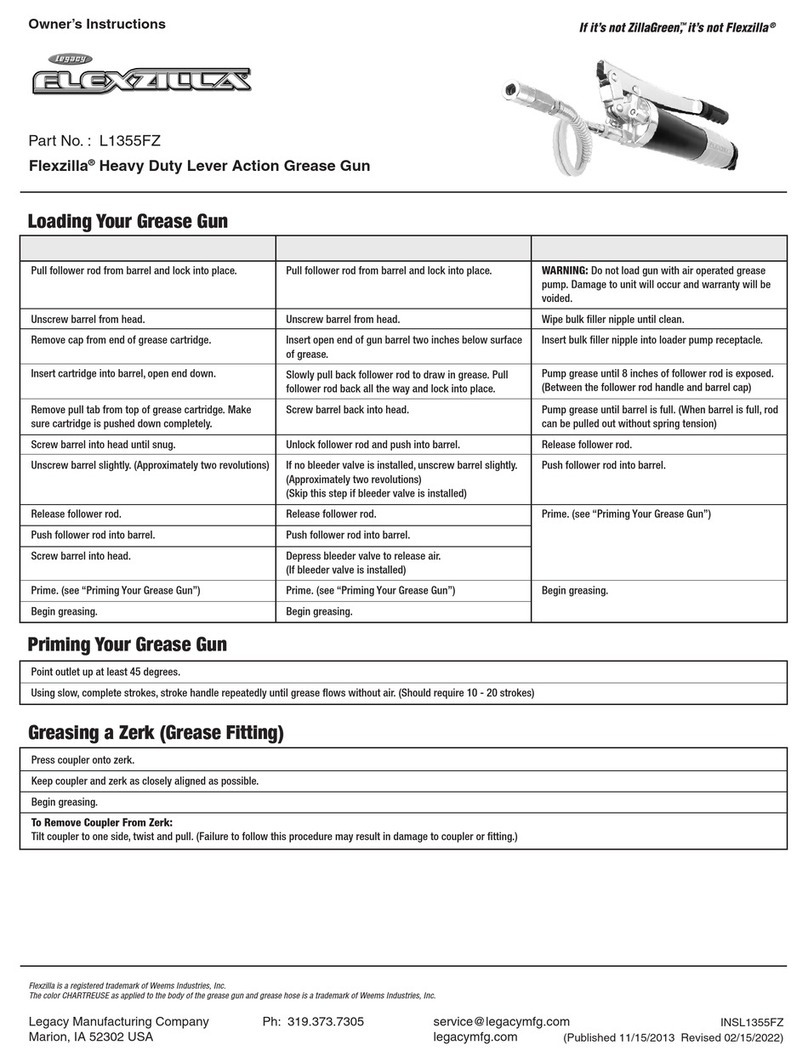

Loading Your Grease Gun

Cartridge Loading Suction Loading Filler Pump Loading

Pull follower rod from barrel

and lock into place.

Pull follower rod from barrel

and lock into place.

WARNING:

Do not load gun with air operated

grease pump. Damage to unit

will occur and warranty

will be voided.

Unscrew barrel from head. Unscrew barrel from head. Wipe bulk filler nipple until clean.

Remove cap from end

of grease cartridge

Insert open end of gun barrel

two inches below surface of grease.

Insert bulk filler nipple

into loader pump receptacle.

Insert cartridge into barrel,

open end down.

Slowly pull back follower rod

to draw in grease. Pull follower rod

back all the way and lock into place.

Pump grease until 8 inches of follower rod

is exposed.

(Between the follower rod handle and barrel

cap)

Remove pull tab from top

of grease cartridge.

Make sure cartridge is pushed

down completely.

Screw barrel back into head.

Pump grease until barrel is full.

(When barrel is full, rod can be pulled out

without spring tension)

Screw barrel into head until snug. Unlock follower rod and push into barrel. Release follower rod.

Unscrew barrel slightly.

(Approximately two revolutions)

If no bleeder valve is installed,

unscrew barrel slightly.

(Approximately two revolutions)

(Skip this step if bleeder valve is installed)

Push follower rod into barrel.

Release follower rod. Release follower rod.

Prime.

(see “Priming Your Grease Gun”)

Push follower rod into barrel. Push follower rod into barrel.

Screw barrel into head. Depress bleeder valve to release air.

(If bleeder valve is installed)

Prime.

(see “Priming Your Grease Gun”)

Prime.

(see “Priming Your Grease Gun”) Begin greasing.

Begin greasing. Begin greasing.

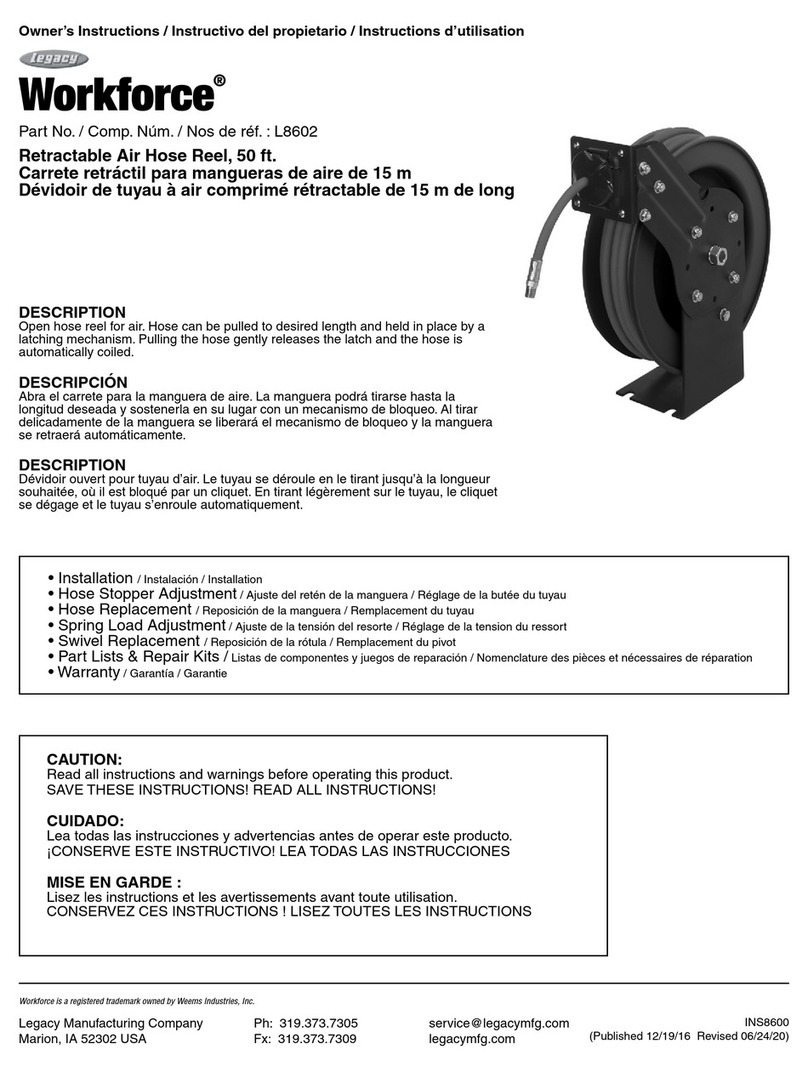

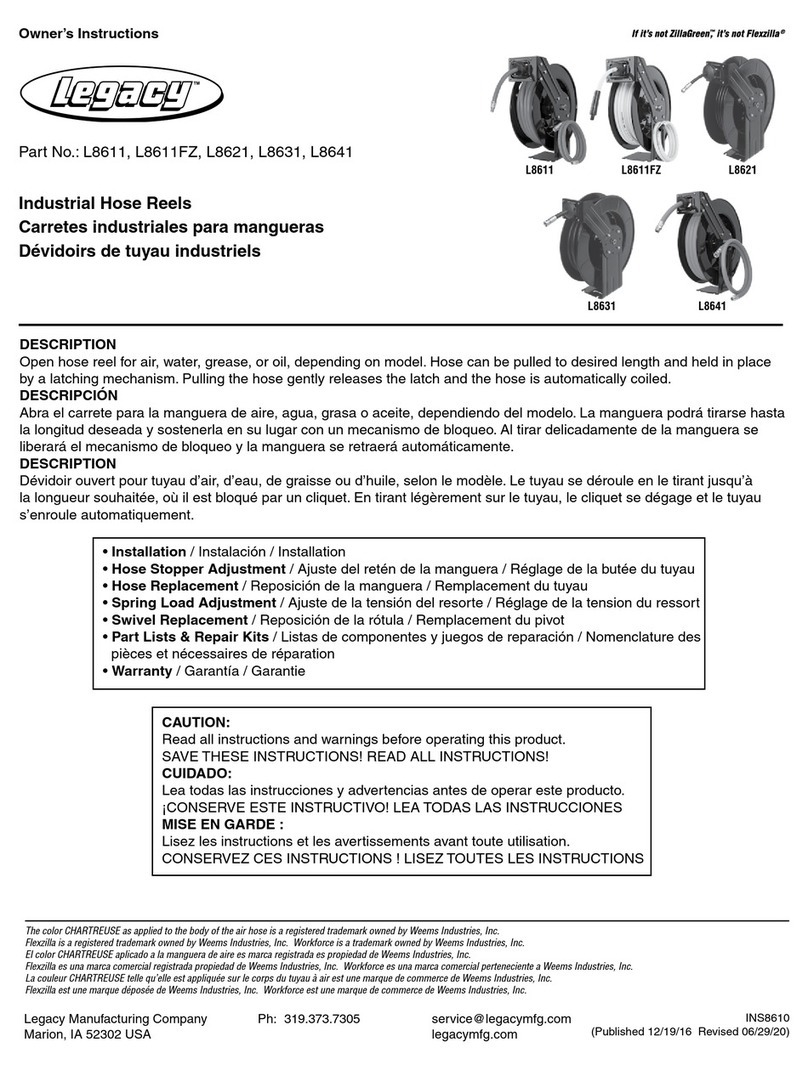

Workforce®Manually Operated Grease Guns

Part No.: L1025, L1310, L1320, L1325,

L1350, L1355, L1355C

Priming Your Grease Gun

• Point outlet up at least 45 degrees.

• Using slow, complete strokes, stroke handle

repeatedly until grease flows without air.

(Should require 10 - 20 strokes)

Greasing a Zerk (Grease Fitting)

• Press coupler onto zerk.

• Keep coupler and zerk as closely aligned as possible.

• Begin greasing.

•To Remove Coupler From Zerk:

• Tilt coupler to one side, twist and pull.

Failure to follow above procedure may result in damage to coupler or fitting.

legacymfg.com

INS1000

(Published 2013-11-15 Revised 2022-02-15)

Workforce is a registered trademark of Weems Industries, Inc.

Legacy Manufacturing Company

Marion, IA 52302 USA

L1025 L1320

L1310 L1325 L1355

L1350 L1355C