Jegs Torch User manual

Monster Truck Assembly Guide

555-44400 - Torch

555-44500 - Hooligan

Assembly Instruction & Parts List

Precautions

Precautions With Small Children

•

For children under the age of 13, parential guidance

is recommended when running.

Assembly Precautions

•

Choking hazard. Do not assemble near small children.

• Check the contents carefully before assembly. Please

contact Customer Service at: 1.800.345.4545 if you

have any defective or missing items.

•

Carefully read through this manual, and familiarize

yourself with the instructions.

•

Many different tools are required during assembly.

For safety purposes, please use the correct tools.

•

Exercise caution when using sharp tools such as a

hobby knife.

•

Many different materials are used in the construction of

these parts. Use extra care when handling parts with

sharp edges, such as machined metal components.

• When cutting plastic parts, watch for any ying parts.

•

Try to assemble any rotating parts or drivetrain parts

as carefully as possible.

•

Bundle wires neatly away from the ground or any moving

drivetrain components. Make sure that all wires are

securely connected to prevent electrical shorting.

Precautions Before Running

•

Some models may exceed speeds of 25 mph. Practice

common sense and run the car in open safe places, or

R/C car tracks.

•

Do not run the car on public roads with high

amounts of trafc, or in areas that may cause an

inconvenience to people in that area.

•

R/C cars are controlled using a radio frequency. In a

worst-case scenario radio interferences may cause

loss of control.

•

If others near you are running R/C cars, conrm that

they are not running on the same frequency.

•

This unit is manufactued with waterproof electronics,

but it should not be submerged in water for extended

periods of time.

• The drivetrain of an R/C car consists of many moving

parts like gears, shafts, and tires. Avoid touching these

areas when the battery is connected.

•

Many parts of an R/C car will become hot after

running. Allow the parts to sufciently cool before

conducting any maintenance.

Beginning a Run

1.

Place the R/C car so that the wheels are off the ground.

2.

Conrm that the speed controller switch is OFF, and

connect the motor and battery.

3. Switch the transmitter ON. (Do not use the transmitter

with low voltage. Ensure that the transmitter batteries

are good before use)

4. Turn the speed controller switch ON.

Ending a Run

1. Turn the speed controller switch OFF.

2. Disconnect the battery.

3. Turn the transmitter switch OFF.

Battery Usage

(Carefully read the instruction included with the batteries.)

•

When charging batteries, ensure nothing ammible

is in the surrounding area. Also avoid charging in

high-temperature locations.

•

When charging batteries, be sure to frequently monitor

the battery. Unattended, it could pose a re hazard.

• If the battery reaches 122º F or more, stop charging.

•

Batteries will become hot after running. Continuous

use of the battery pack may result in damage to

the cells. Allow the battery too cool down before

re-charging. Using a battery conditioner after running

may prolong the life and performance of the battery.

•

Please do not discard old battery packs in the trash.

Locate a battery disposal center.

Motor Usage

(Carefully read the instruction included with the motor.)

• Connecting a 7.2V battery directly to the motor can be

very dangerous.

•

Choose the appropriate gear ratio that matches the

motors power characteristics.

•

Using a gear ratio not suited to the characteristics of the

motor will not only prevent the motor from performing

at its optimum, but may damage the other electronics.

•

Motors will generally become very hot after running.

Continuous running will reduce the life of the motor.

Allow the motor to sufciently cool between each run.

1

Tools Required

Equipment Required

1.5 mm 2.0 mm 2.5 mm Socket

Wrench

Philips Screwdriver

(Not Included)

Battery

(Not Included)

Battery Charger

(Not Included)

Gear Grease

(Not Included)

Shock Oil [Silicone]

(Not Included)

Threadlock

(Not Included)

2

Shock Assembly

Bag A

555-44816

Shock Piston

555-44702

Shock Shaft

555-44858

O-Ring

555-44670

E-Clip

555-44816

Shock Shaft Guide

555-44806

3x6x0.5mm Washer

555-44816

Shock Body

555-44859

O-Ring (Black)

555-44816

Lower Ball End

Insert shaft guide and oil ring

into shock shaft as shown in

diagram. Make sure the shaft

guide is fully seated in the

shock body, refer to diagram.

555-44814

Shock Cap

555-44816

Upper Ball End

555-44813

Shock Diaphram

555-44816

Lower Shock Holder

555-44816

Shock Lower Rod End

555-44816

Spring Spacer

555-44816

Upper Spring Holder

555-44816

Shock Spring

3

555-44814

Shock Cap (Black)

555-44816

Upper Ball End

555-44806

3x6x0.5mm

Washer

555-44816

Shock Lower

Rod End

555-44813

Shock

Diaphram

555-44816

Shock Piston 555-44702

Shock Shaft

555-44858

O-Ring

555-44816

Spring Spacer

555-44816

Spring Holder

555-44816

Shaft Guide

555-44815

Shock Spring

55544859

O-Ring (Black)

555-44706

5.8mm Flanged

Pivot Ball

555-44816

Lower Spring

Holder

555-44816

Shock Body

555-44670

E-Clip

555-44706

5.8mm Flanged

Pivot Ball

555-44706

5.8mm Flanged Pivot Ball

Shock Assembly Continued

Bag A

Assembly x8

4

Front & Rear End Assemblies

Bag B

555-44726

Differential Case

555-44738

Planetary Gear

555-44857

10x12.5x0.1mm Shims

555-44738

Sun Gear

555-44817

Ring Gear M1x30T

555-44758

M2x8mm FH

555-4473210x15x-

4mm Bearing

555-44732

10x15x4mm Bearing

Assembly x2

555-44879

O-Ring (Black)

555-44856

5x7x0.2mm Shims

555-44734

5x10x4mm Bearing

555-44694

Differential Housing

555-44819

Drive Cup

555-447325x10x-

4mm Bearing

555-44818

Pinion Gear M1x13T

555-44758

M2x8mm FH

Assembly x2

Use Grease

Use Threadlocker

5

Front End Assembly

Bag B

555-44694

Differential Cover

555-44776

M3x18mm BH

555-44746

M2.5x18mm BH

555-44694

Solid Axle

555-44704

4-Link Bracket

B

A

555-44678

King Pin

555-44724

C Hub_B

555-44734

5x10x4mm Bearing

555-44760

M3x10mm BH

555-44690

Front Axle Shaft

555-44724

C Hub_A

555-44820

Wheel Axle

555-44678

King Pin

555-44822

Wheel Nut

555-44762

M3x10mm CH

555-44678

King Pin

555-44734

5x10x4mm Bearing

555-44724

C Hub_B

555-44724

C Hub_A

Front Front

Castor Angle Adjustment:

Recommended at the highest point, refer to the

diagram. Each point is a 15º increment increase.

About 3-3.5 mm

6

Front End Assemblies Continued

Bag B 555-44698

Lower Link (275WB)

555-44707

5.8mm Pivot Ball

555-44698

Upper Link (275WB)

555-44766

M3x14mm BH

About 10.3 mm

555-44800

M3x25mm Turnbuckle

555-44708

5.8mm Rod End

555-44706

5.8mm Flanged Pivot Ball

555-44708

5.8mm Rod End

555-44766

M3x14mm BH

555-44778

M3x30mm BH

555-44808

3x6x1mm Spacer

555-44810

3x6x2mm Spacer

555-44776

M3x18mm BH

555-44662

M3 Nylon Locknut

555-44662

M3 Nylon Locknut

555-44708

5.8mm Rod End

555-44708

5.8mm Rod End

555-44706

5.8mm Flanged Pivot Ball

555-44696

Steering Drag Link

7

Front End Assemblies Continued

Bag B

555-44706

5.8mm Flanged Pivot Ball

555-44706

5.8mm Flanged Pivot Ball

555-44708

5.8mm Rod End

555-44708

5.8mm Rod End

555-44804

M3x90mm

Turnbuckle

About 71.1mm

555-44766

M3x14mm BH

8

Rear End Assemblies

Bag B

A

B

B

A

555-44694

Differential Cover

555-44776

M3x18mm BH

555-44746

M2.5x18mm BH

555-44694

Solid Axle

555-44704

4-Link Bracket

Adjustable Anti Squat

15º Increments

555-44692

Rear Axle Shaft

555-44734

5x10x4mm Bearing

555-44854

2x10mm Pin

555-44833

Straight Axle Adapter

555-44760

M3x10mm BH

555-44822

Wheel Hex

9

Front & Rear End Assemblies

Bag B

Rear End Assembly

555-44766

M3x14mm BH

555-44698

Upper Link (275WB)

555-44707

5.8mm Pivot Ball

555-44698

Lower Link (275WB)

10

Center Differential Assembly

Bag C

Use Grease

Use Threadlocker

555-44736

5x8x2.5mm Bearing

555-44734

5x10x4mm Bearing

555-44825

2nd Gear

(Metal)

555-44722

Transmission Gear Box A

555-44722

Transmission Gear Box

Adjuster Cap

555-44794

M3x8mm Cap

555-44734

5x10x4mm Bearing

555-44855

2.8mm Pin

555-44825

Idle Gear

(Metal)

555-44700

2nd Gear Shaft

555-44821

Main Gear Shaft

555-44722

Transmission Gear Box B

555-44732

5x15x4mm Bearing

555-44758

M2x8mm FH

555-44825

Final Gear

(Metal)

555-44718

Center Locker

11

Center Differential Assembly Continued

Bag C

Recommended Slipper

Clutch Adjustment:

Tighten (clockwise) the

slipper nut until it stops

then back it off (counter

-clockwise) 3/4turn.

Use Grease

Use Threadlocker

555-44854

2x10mm Pin

555-44760

M3x8mm Cap

555-44830

Slipper Hub Set

555-44826

Slipper Pad

555-44794

M3x8mm Cap

555-44824

48P 85T Spur Gear

555-44852

M3x6mm Cap

555-44831

Slipper Spring

555-44740

M4 Nylon

Locknut

555-44710

5x10mm

Thrust Bearing

High Torque Ratio

(Standard)

High Speed Ratio

555-44837

Transmission Bracket

555-44760

M3x10mm BH

555-44776

M3x18mm BH

12

Use Threadlocker

Use Threadlocker

555-44840

ST Wiper B

555-44840

ST Wiper A

555-44840

ST Wiper C

555-44678

King Pin

Set the gear mesh

about 0.1mm gap

555-44680

RS 550 Motor

555-44827

48P 16T Motor

Pinion Gear

555-44843

Motor Heat

Sink Plate

555-44792

M3x8mm BH

Center Differential Assembly Continued

Bag C

555-44784

M23mm

Set Screw

555-44812

M3x7x0.25mm Washers

13

Center Differential Assembly Continued

Bag C

555-44792

M3x8mm BH

555-44790

M3x6mm FH

555-44720

Drive Cup (4.5mm)

555-44829

O-Ring (Black)

555-44838

Skid Plate

555-44720

Drive Cup (4.5mm)

555-44829

O-Ring (Black)

555-44722

Transmission

Gear Box Cover

14

Radio Tray

Bag D

555-44748

M2.5x6mm BH

555-44838

Receiver Cover

555-44750

M2.5x8mm BH

555-44838

Dust Cover

555-44684

Receiver

Double-Sided

Foam Tape

555-44838

Receiver Box

555-44792

M3x8mm BH

555-44792

M3x8mm BH

555-44792

M3x8mm BH

555-44792

M3x8mm BH

555-44716

Bumper Bracket

555-44760

M3x10mm BH

555-44792

M3x8mm BH

555-44836

Servo Tray

555-44688

275WB Chassis

Extension Plate

15

Radio Tray Continued

Bag D

Use Threadlocker

555-44676

40Amp ESC

Double- Sided

Foam Tape

555-44792

M3x8mm BH

555-44844

Servo

555-44812

3x7x0.25mm Washers

555-44764

M3x12mm BH

555-44841

Servo Saver Cap

About 48.5mm

555-44802

M3x25mm Turnbuckle

555-44706

5.8mm Flanged Pivot Ball

555-44708

5.8mm Rod End

555-44708

5.8mm Rod End

555-44706

5.8mm Flanged Pivot Ball

555-44770

M3x12mm BH

555-44841

Servo Saver Cap

555-44853

Servo Saver Spring

555-44841

Servo Arm

555-44662

M3 Nylon Locknut

16

Radio Tray Continued

Bag D

555-44852

Set Screw Shaft

555-44714

Body Post

Radio Tray Assembly

17

555-44712

Battery Tray

555-44678

King Pin

555-44836

Rear Bumper Stay

555-44792

M3x8mm BH

555-44792

M3x8mm BH

555-44792

M3x8mm BH

555-44760

M3x10mm BH

555-44716

Bumper Bracket

555-44852

Set Screw Shaft

555-44714

Body Post

Battery Tray

Bag E

18

Chassis

Bag G

555-44674

Center Drive Shaft

555-44674

Center Drive Shaft

555-44766

M3x14mm BH

19

This manual suits for next models

3

Table of contents

Other Jegs Motorized Toy Car manuals

Popular Motorized Toy Car manuals by other brands

HPI Racing

HPI Racing Firestorm 10T instruction manual

LEGO

LEGO Racers Supersonic RC 8366 Building instructions

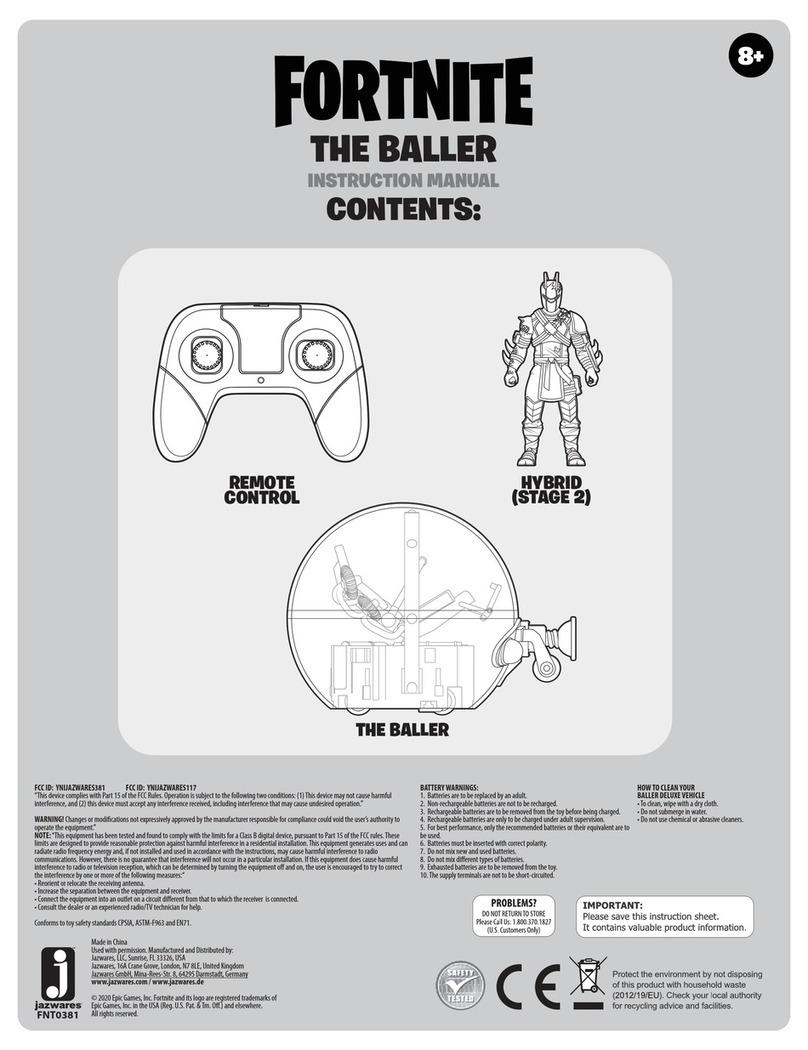

Jazwares

Jazwares Fortnite The Baller instruction manual

DeAGNOSTINI MODEL SPACE

DeAGNOSTINI MODEL SPACE Red Bull Racing RB7 Build manual

AK

AK FJ43 PICKUP with SPG-9 recoilless gun Assembly instructions

Arrma

Arrma 4x4 3S BLX quick start guide

Carrera RC

Carrera RC RC POWER FIRST Carrera RC Racer Assembly and operating instructions

SWorkz

SWorkz S35-GT instruction manual

KID Trax

KID Trax KT1309TR manual

RED CAT

RED CAT Tremor SG instruction manual

Spinmaster

Spinmaster DC BATMOBILE RC quick start guide

KID Trax

KID Trax SRT Viper KT1124WM owner's manual