2

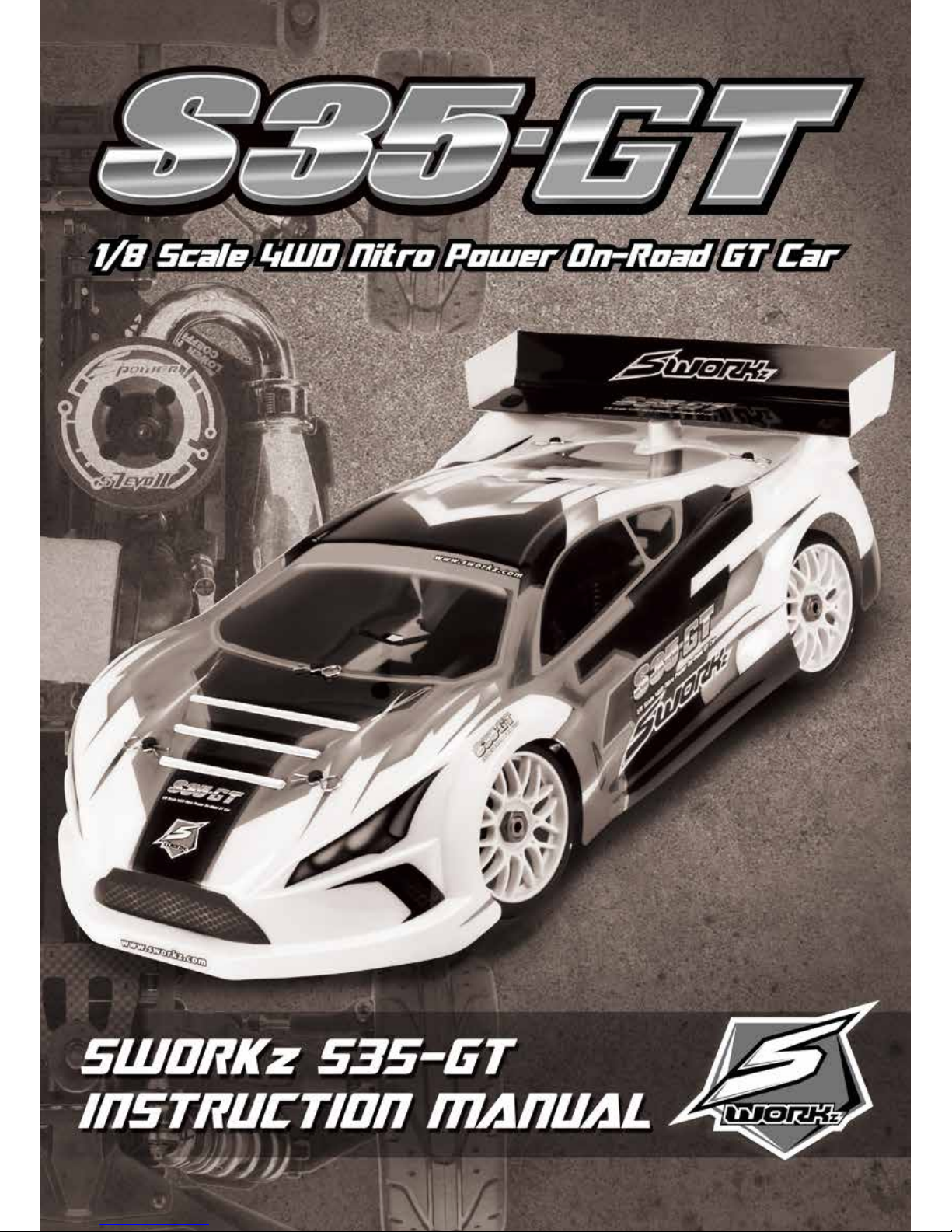

1. S35-GT series Nitro on-road GT Car T-7075 Aluminum Lightened Main Chassis with L.F.C

system (Lower Friction Coefficient)

2. S35-GT Series Front and Rear Pro Shock Towers made of Lightened T-7075 Aluminum for

GT-BBS shocks system.

3. S35 Series BBS Emulsion Shock Caps.

4. S35-3 Series Lightened Transmission Gear Box System with High Performance Crown

Gears and Pinion Gears.

5. Front and Rear Universal Drive Shafts with Special Lightened 6mm Axle Wheel Hub system.

6. S35-3 Series Aluminum Rear Lower Fully Adjustable Toe-In Block (A).

7. S35-3 Series Competition Aluminum Steering Knuckle Plates.

8. S35-GT new center 2 speed on-road transmission system.

9. S35-GT/GTE On Road Bumper and rear body poster system.

10. Heavy Duty Front and Rear Arms .

11. Professional 2.0 Metal Brake Calippers.

12. New 150cc Floating Fuel Filter System Tank.

13. Adjustable Front Upper and Lower Suspension Arm System.

14. S35-3 Series Pro-composite Carbon Front Upper Arm Covers.

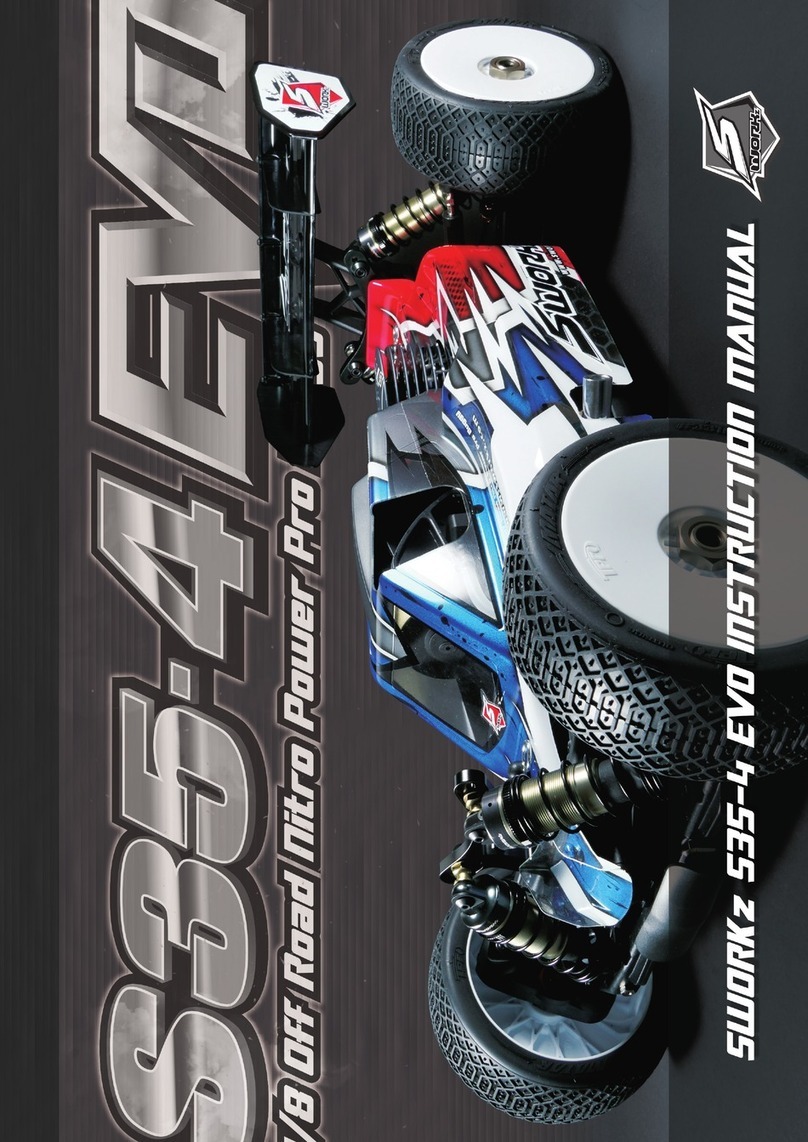

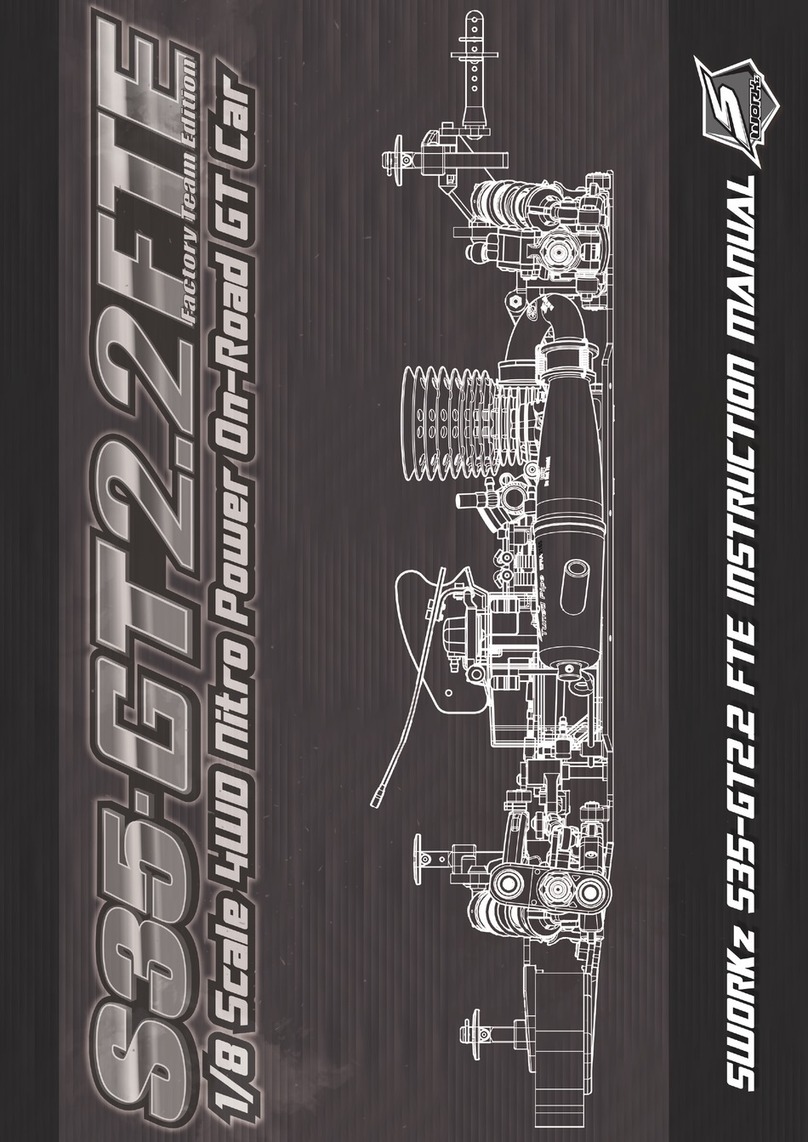

INTRODUCTION

Based on the latest SWORKz S35-GTE platform, SWORKz further developed and improved the

nitro GT and came up with the S35-GT.

The S35-GT is the ultimate SWORKz 1/8th nitro On-Road GT Car at this moment. Its front and

rear suspension design is shared with the S35-GTE. The Ackermann steering system came

directly from the 1/8th S35-3 nitro Buggy. A new center 2 speed on-road transmission system

gives perfect acceleration to the S35-GT.

The S35-GT newly designed arms are made from a strong nylon material. Optional carbon

covers are available to adjust the arm's stiness for dierent tracks.

The new unique front shock tower design allows to change the front upper angle position

easily.

The T-7075 aluminum chassis with its new design L.F.C (Lower Friction Coecient) system will

give more grip and at the same time less friction for the rear.

A new radio tray system provides better and more precise throttle and braking response.

The S35-GT includes high quality parts, an refined shock system, more options and an

optimized suspension geometry.

SWORKz utilizes only the highest quality materials and industry leading manufacturing

processes, resulting in a faster, stronger and more reliable vehicle. The SWORKz S35-GT 1/8

Pro Nitro On-Road GT Kit has been designed to out-perform the competition on any On-Road

track, while oering amazing performance to drivers of all levels.

Congratulations on your purchase of the new SWORKz S35-GTE 1/8 scale on-road racing GT

pro kit.

Please read this manual thoroughly before you attempt to start running your S35-GTE. This

manual contains step-by-step instructions to help you complete, prepare for startup, and ne-

tune your Buggy. Updates, setups, and product news will be posted on our website (www.

sworkz.com) or SWORKz RC Face Book page.

As always, if you should ever have any questions or need help with your S35-GT, please feel

free to contact our ocial SWORKz dealers and distributors, as they will be glad to help you.

You may also contact us at any time for the most up to date information and support.

S35-GT Kit Features: