WE ARE HERE TO SURPRISE!

3

1. Important safety instructions

1.1 Important notices

Jema Autolifte will give the user one-year warranty of quality for the lift. If something is wrong with the lift, Jema Autolifte or the

distributor will provide the spare part for it to be replaced. Jema Autolifte will not take any responsibility for improper installation,

wrong operation, overload of the max. Lifting capacity, wrong concrete ground (that can not meet the requirements in the manual),

normal mechanical abrasion and insufficient maintenance. The warranty will be carried outon the basis of the typeand serial number

of the equipment. When contacting Jema Autolifte or the distributor the users shall provide picture documentation if asked.

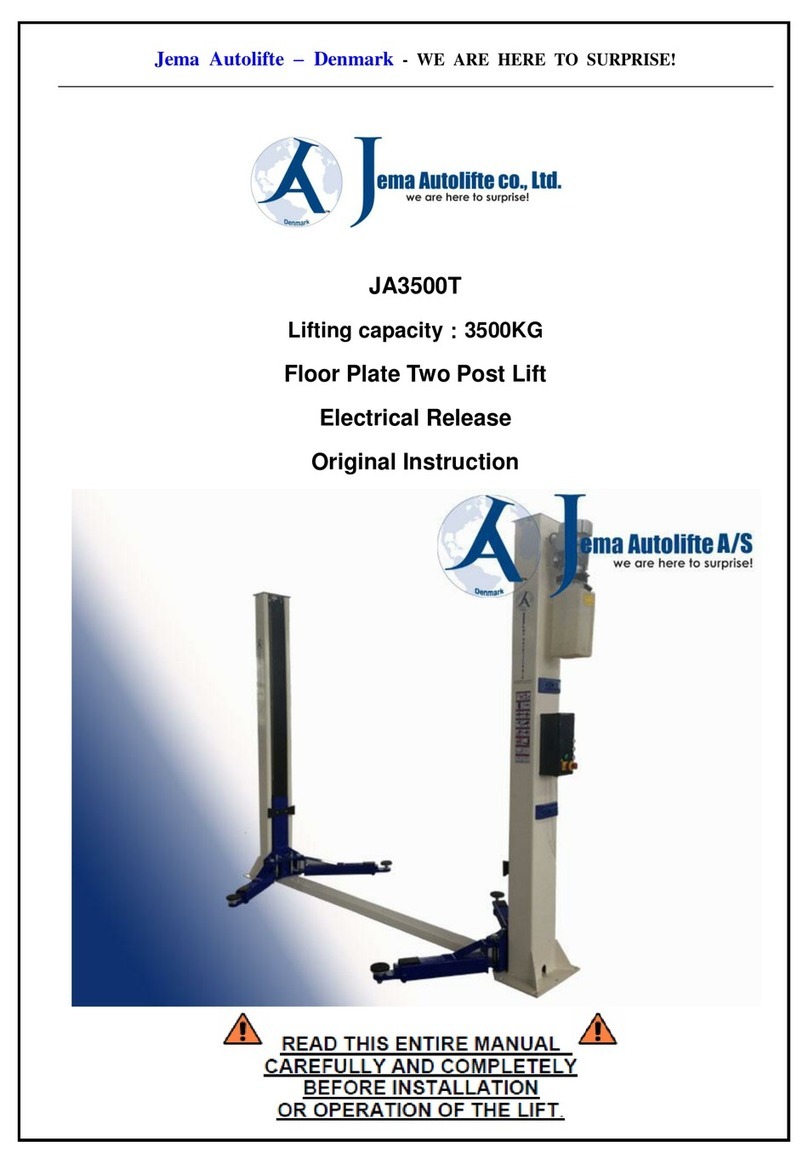

The 2-post lift is suitable for lifting motor vehicles having maximum weight as described, any other use is to be considered improper

and irrational and thus highly forbidden. Jema Autolifte cannot be held responsibilities for any damage or injuries caused by an

improper use or by the non-observance of the following instructions.

Read this guide carefully before using the lift and follow the instructions given by this guide to grant the lift a correct function,

efficiency and a long service life.

1.2 Qualified personnel

1.2.1 The lift may only be used by qualified staff, properly trained for the specific use of the lift.

1.2.2 The wiring must comply with local code and a certified electrician for electrical hook up.

1.2.3 Only authorized personnel are allowed in lifting area.

1.3 Danger notices

1.3.1 Do not install the lift on any asphalt surface.

1.3.2 Read and understand all safety warning procedures before operating the lift.

1.3.3 The lift, in its standard version, is not designed for outdoor use.

1.3.4 Keep hands and feet away from any moving parts. Keep feet clear of lift when lowering.

1.3.5 The lift may only be used by qualified staff, properly trained for the specific use of the machine.

1.3.6 Do not wear unfit clothes such as large clothes with flounces, tires, etc, which could get caught by moving parts of the machine.

1.3.7 The lift surrounding area must be free from people or objects which could be a danger for lifting operations.

1.3.8 The lift is only designed to lift the entire body of vehicle, having maximum weight not more than the lift capacity.

1.3.9 Always insure the safety devices are engaged before any attempt to work on or near vehicle.

1.3.10 The vehicle must be centered and positioned in a stable correct way and following the instructions given by Jema Autolifte.

1.3.11 Make sure that the lift and its devices are working correctly, according to the specific instructions for maintenance

1.3.12 Lower the lift to its lowest position when finished.

1.3.13 Do not modify the lift without Jema Autolifte’s advice.

1.3.14 If the lift is not to be used anymore, owners is suggested to removing thepower supply connections, emptying the oil tank and

disposing the liquids by right way.

1.3.15 If the lift is to be left unused for a long period, proceed as follows:

a. Disconnect the energy source.

b. Empty the oil tank.

c. Grease the moving parts which might be damaged by dust or drying out.