4

NOTES: After making the countertop cutout, some installations

may require notching down the base cabinet side walls to clear

the cooktop base. To avoid this modification, use a base cabinet

with sidewalls wider than the cutout.

■Where possible, a 6" (15.2 cm) clearance is recommended for

motor blower service. A minimum clearance of 1" (2.5 cm) is

recommended to the sidewalls and a ³⁄₄" (1.9 cm) clearance is

recommended to the rear wall.

■A minimum clearance of 2" (5.1 cm) is recommended

between the motor/blower and cabinet for proper cooling.

■A minimum clearance of 6¹⁄₄" (15.9 cm) is recommended for

removal of the grease container(s). Installed dimension for the

grease containers is 5¹⁄₂" (14.0 cm).

■For grills installed near a sidewall, a minimum clearance of

6" (15.2 cm) is recommended between the cooktop and

sidewall for maximum performance.

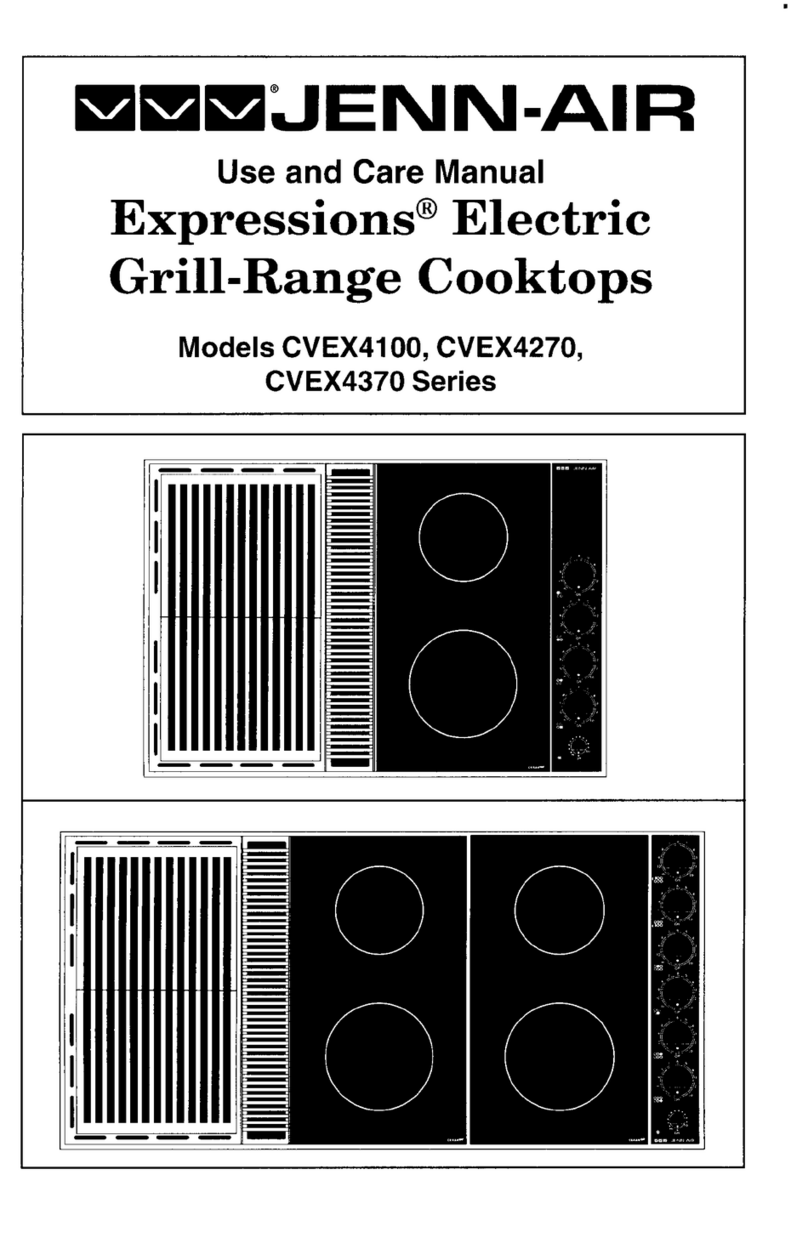

Cutout Dimensions

Venting Requirements

■Do not terminate the vent system in an attic or other enclosed

area.

■Use a Jenn-Air®vent cap.

■Vent system must terminate to the outside.

■Use only a 6" (15.2 cm) round metal vent. Rigid metal vent is

recommended. For best performance, do not use plastic or

metal foil vent.

■Before making cutouts, make sure there is proper clearance

within the wall or floor for the exhaust vent.

■Do not cut a joist or stud unless absolutely necessary. If a

joist or stud must be cut, then a supporting frame must be

constructed.

■The size of the vent should be uniform.

■The vent system must have a damper. If roof or wall cap has a

damper, do not use damper supplied with the range hood.

■Use only a 6" (15.2 cm) round metal vent or a 3¹⁄₄" x 10"

(8.3 x 25.4 cm) rectangular metal vent except for as follows:

■For electric models, 5" (12.7 cm) diameter round metal

vent may be used for venting straight out the back of the

cooktop and directly through the wall for a duct length of

10 ft (3.0 m) feet or less.

■For gas models, 5" (12.7 cm) diameter round metal vent

must be used if the duct length is 10 ft (3.0 m) feet or less.

■Do not use 5" (12.7 cm) elbows except in a 5" (12.7 cm)

system. Instead, use a 5" (12.7 cm) to 6" (15.2 cm) elbow or a

5" (12.7 cm) to 3¹⁄₄" x 10" (8.3 x 25.4 cm) elbow transition.

■Use vent clamps to seal all joints in the vent system.

■Use caulking to seal exterior wall or roof opening around the

cap.

■Determine which venting method is best for your application.

For Best Performance:

■Use 26-gauge minimum galvanized or 25-gauge minimum

aluminum metal vent. Poor quality pipe fittings can reduce

airflow. Flexible metal vent is not recommended.

NOTE: Local codes may require a heavier gauge material.

■Metal duct may be reduced to 30-gauge galvanized steel or

26-gauge aluminized steel if allowed by local codes. This

reduction is based on information in the International

Residential Codes Section M1601.1 (2006 edition).

■Do not install 2 elbows together.

■Use no more than three 90° elbows.

■If an elbow is used, install it as far away as possible from the

hood’s vent motor exhaust opening.

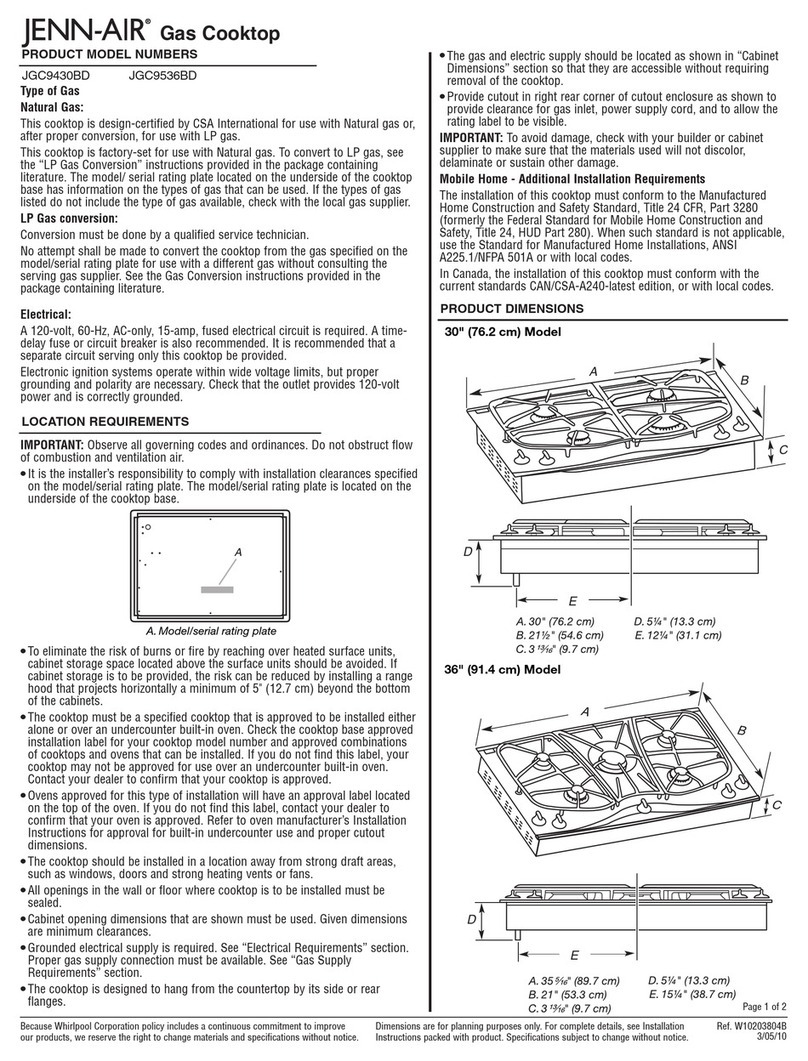

A. 29" ±¹⁄₁₆" (73.6 cm ±0.2 cm) on 30" (76.2 cm) models

43¹⁄₄" ±¹⁄₁₆" (109.9 cm ±0.2 cm) on 45" (114.3 cm) models

B. 21" ±¹⁄₁₆" (53.3 cm ±0.2 cm) maximum on both 30" (76.2 cm) and

45" (114.3 cm) models

C. 9³⁄₈" (23.8 cm) on both 30" (76.2 cm) models and 45" (114.3 cm)

models

D. 7⁹⁄₁₆" (19.2 cm) on both 30" (76.2 cm) and 45" (114.3 cm) models

E. 1⁷⁄₈" (4.8 cm) minimum space to front edge of cooktop

F. Floor exhaust option

G. 6¹⁄₈" (15.6 cm) for 6" vent system

H. 9³⁄₈" (21.9 cm) on both 30" (76.2 cm) and 45" (114.3 cm) models

I. 13" (33.0 cm) on both 30" (76.2 cm) and 45" (114.3 cm) models

J. Wall exhaust option

AB

CD

E

F

G

H

I

J