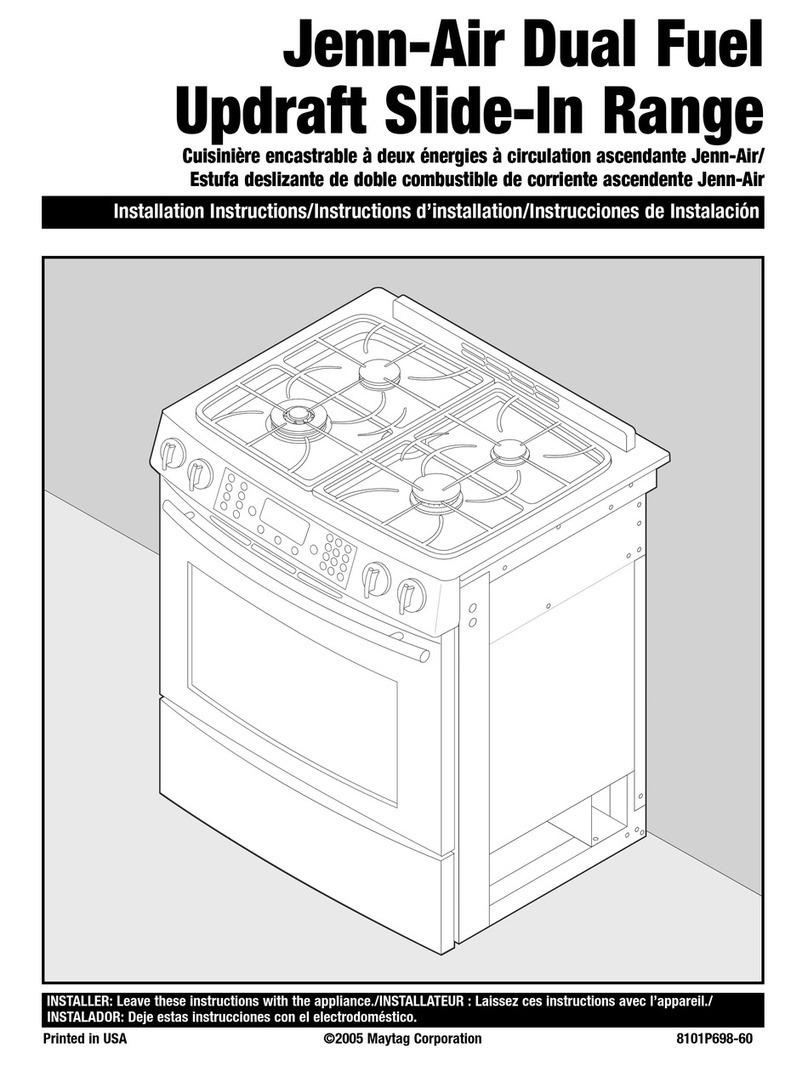

CONNECTINGAPPLIANCE TO GAS SUPPLY

ATRAINEDSERVICEMAN ORGAS APPLIANCE MAXITROL REGULATOR _

_BSCBNBT0

INSTALLER MUST MAKE THEGASSUPPLY ._ u, _Pu_mm_.CONNECTION. Leak testing of the appliance shall be

conducted by the installer according to the instructions cm_,=;"_ _=_-=_ ___

&qpJ _P_ISUm_

given._T¥ .-- " _T'T" }_-

INSTALLGASSHUTOFFVALVE _ _ (_

Install amanual shutoffvalveinanaccessible locationin

thegas lineexternal to thisapplianceforthe purposeof

turningon or shuttingoffgasto theappliance.

Make thegas connectiontothe inletofthepressure

regulatoron thisappliancewith a 1/2"malepipethread,ILLUSTRATION "A"

Use anapprovedpipejointcompoundresistantto the

actionofLP gasat pipeconnections.Test alljointsforHARPER-WYMAN REGULATOR

gas leakswith a soapandwater solutionor other \ _J

acceptedleak detection means.Never test for gas leaks _ Therevers_lecapis

withanopen flame, labeledeither"LP"or

"NAT"andiseasily

PRESSURE TESTING recognizedby61e

The maximumgas supply pressurefor theregulator _ ._raisedcantercoinslot

suppliedon this applianceis 14_Water Column. Thetest (_(_ (forNatural)orthe

pressure for checkingthisregulator must be at least6"cer_rwell(forLP).

Water Columnfor naturalgas, andat least11"Water

Columnfor LP. Itis shippedfrom the factory setfor ..,,=_== _=e,=,,=

naturalgas at 5" WaterColumn. ALTERNATE ILLUSTRATION "A"

Thisapplianceand itsindividualshutoffvalvemustbe

disconnectedfromthegas supplypipingsystemdudng

any pressuretestingofthatsystem at testpressuresin wrench-tighteneduponreplacement.Firm finger

excessof1/2 PSIG (3.5 kPa). tighteningwillsecurethe cap.)

Thisappliancemustbe isolatedfromthegassupplyTo convertregulatorto LP inserta coin intothe slotin the

pipingsystembyclosingitsindividualmanualshutoff capofthe regulatorand turncounterclockwiseto loosen.

valveduringanypressuretestingofthe gassupplypipingReverse(invert)cap,pushdownandturnclockwiseto

systemattest pressuresequalto or lessthan1/2 PSIGlockinplace.Whenfinished,themarking"LP"shouldbe

(3.5k Pa). visibleinthe centerwellofthecap.

APPLIANCE PRESSURE REGULATOR CONVERSION TO LPGAS (See illustration "B")

CONVERSION (See illustration"A") Thisappliance isshippedfromthefactoryequipped for

Followtheinstructionsbelowto converttheregulatorforusewithnaturalgas. To convertitfromnaturalgasfor

usewithLPgas. (Thisapplianceisshippedfrom theusewithLPgas, performsteps 1through4.

factoryadjustedforusewithnaturalgas.)

1. Unscrewthehex shapedcap fromtheneckof the/_ _/t

regulator. (Awrench may berequiredtoloosenthe{[/

cap.) 1/2"OPEN END

WRENCH.I)

2.Withinthe cap is aplasticpin.Remove this pin from /.

the cap by applying sideward pressuretothe pin. (See TURNCLOCKWISE

illustration,)TURN _1 lieTO TIGHTEN

COUNTERCLOCK'WlSE

3.Invertthepinand snapit backinto placewithinthecap TOREMOVEORIFICEHOOD

by applyingevenfingerpressureat opposingedgesofILLUSTRATION "B"

thepin'scirculardisc.The pinmustbe seatedfirmly

and squarelyinthecap, 1.Removenaturalgas orificehoods.Remove LP orifice,

Pinreplacement may be most easilyaccomplished by(ifsoequipped) in tube assemblies.Install colorcoded

placing the cap on a flat horizontal surface, as shown in orifice hoods supplied. (SEE LPGAS CONVERSION

the illustration,and applyingdownwardfingerpressure INSTRUCTIONS PAGE 15.)

at the edgesofthe pin'sdisc. 2. Invert cap inconvertiblepressureregulator(if so

4.Screw the cap securely back into place in the neck of equipped) located at entrance to gas manifold.

the pressure regulator.(The capneed not be -11-