CONTENTS

Page

l o

INTRODUCTION

·

.......

.

..................

.

.......................

1-

1

1 . 1

General

..................................•........•.......

1

-1

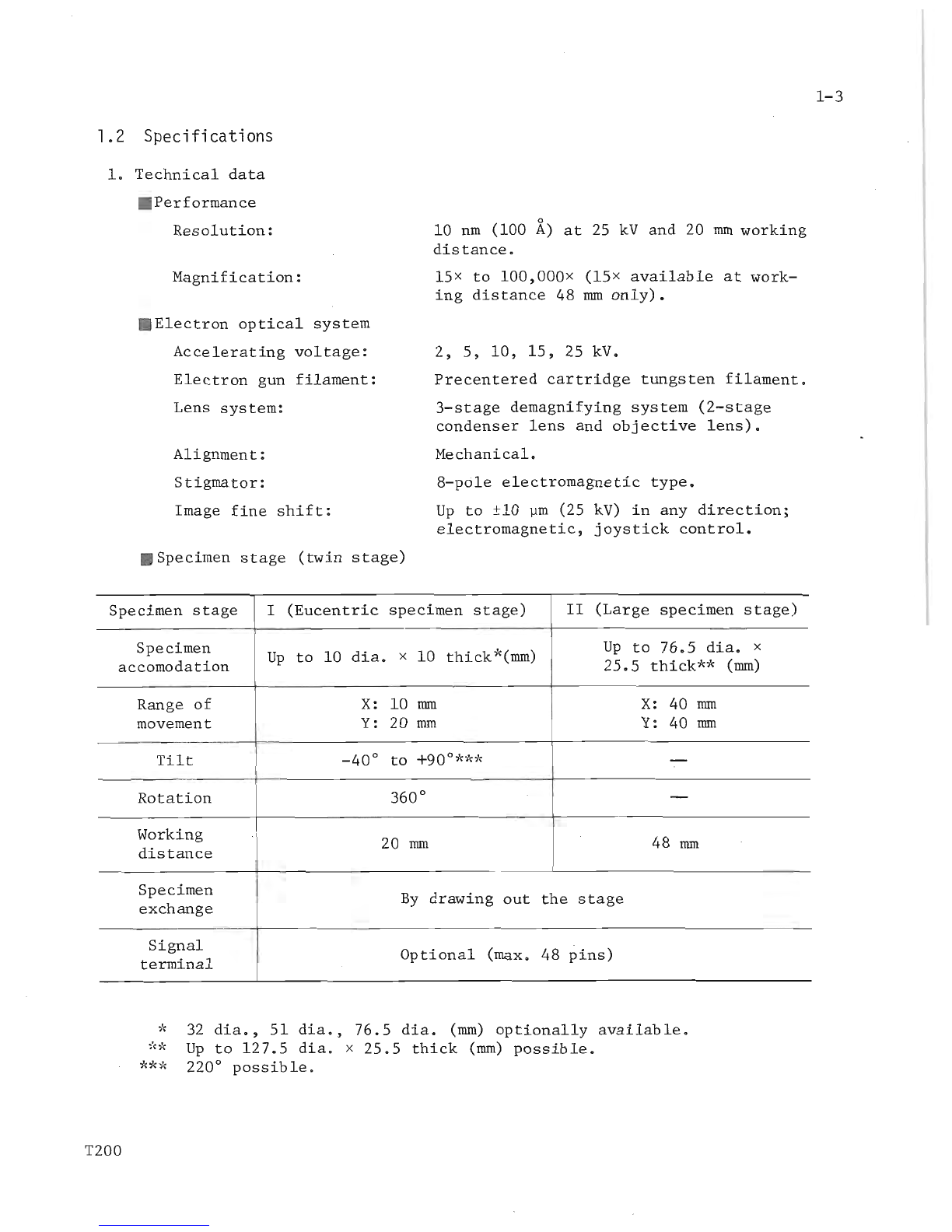

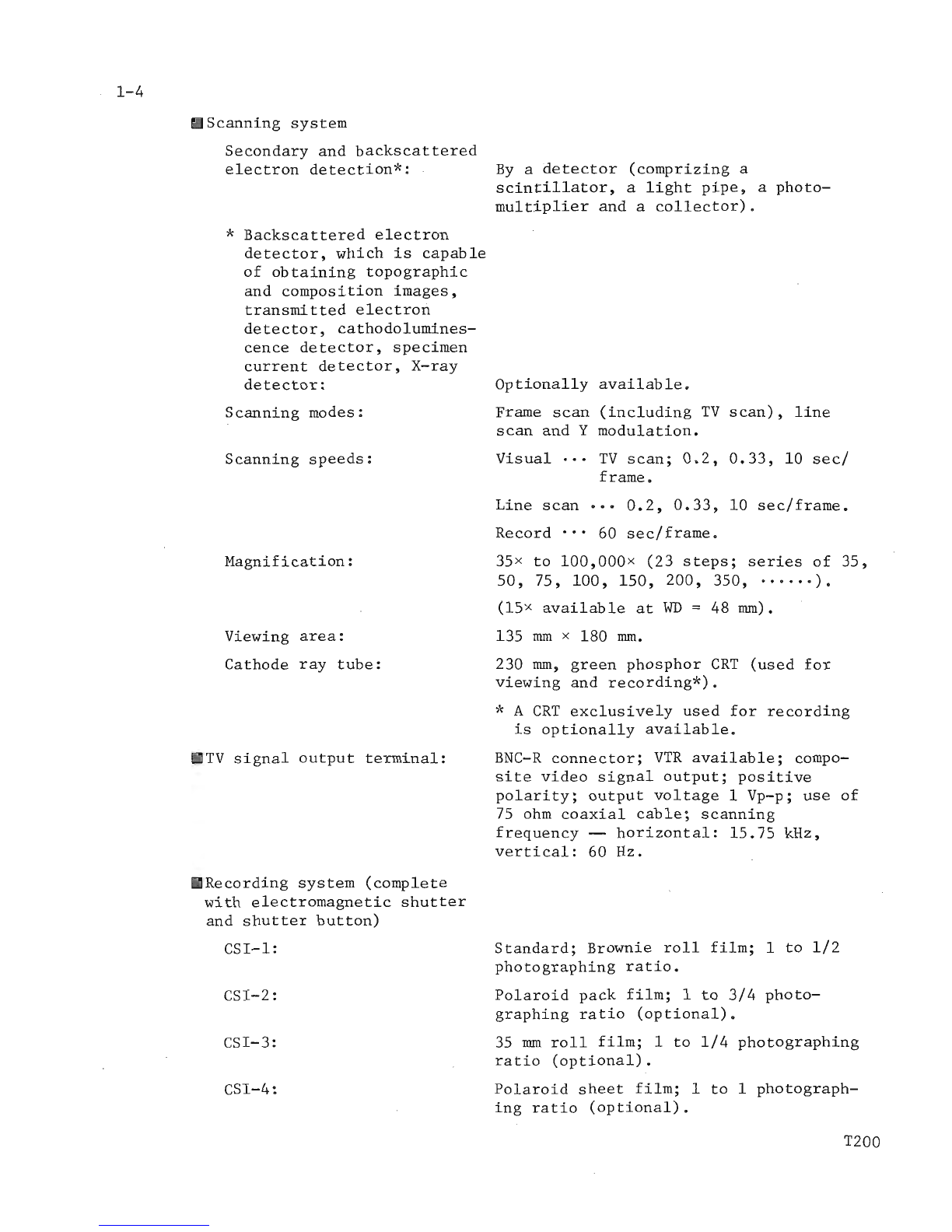

1. 2

Specifications

...................•..•....•....•...........

1

-3

1.

3

Layout

,

dimensio

ns

and

weight

...........•..••..........•..

1

-6

2.

DESCRIPTION

OF

MAIN

UN

IT

S

......................................

2-1

2.1

Column

and

specimen

s t a ge

•....................•.........•.

2-2

2 . 2

Display

panel

.....................................•.......

2- 3

2. 3

Checker

•....

..

.......

.

.....................••..•........

' .' 2- 5

2 . 4

Control

panel

···········

·

···················

. .

............

2-7

3.

OPERATION

·

..

....

.

..

..

..........................................

3

-1

· 3. 1

Startup

and

shutdo

wn

...................•......

.

..

.

........

3-1

3. 1 . 1

Star

t

up

'"

................•........................

3-1

3 . 1 . 2

Shutdown

····

···

·······

·

·················

·

··

·

·······

3-1

3.1

. 3

Power

failure

.........•............................

3

-1

3. 1 . 4

Water

failure

•...................

.

..........

...

....

3

-1

3.2

Specimen

mounting

. .

....

.

...................•..............

3

-2

3.

2.1

Specimen

preparation

....

.

...

.

.................•....

3-

2

3.

2.2

Eucentric

specimen

stage·

············

·

··

...

.

.......

3-

2

3. 2. 3

Large

specimen

stage

.

...

.

...

.

...........•......

. . . .

3-3

3. 3

Image

observation

....

.

.........................

.

..

.

......•

3-

5

3.3

. 1

Secondary

electron

image

(SEI)

. .

......

.

.......

.

....

3-

5

3.3

. 2

Backscattered

electron

image

(BEl)

. .

....•..........

3-7

3.3

. 3

Adjusting

the

rapid

ex

posure

marker

. .

..

...

..

..•.

. . ..

3-8

3.3.4

Astigmatism

correct

i

on

...

.

....

.

.....

..

. .

......

..

..

. 3- 9

3. 3. 5

Autom

a

tic

foc

us

mode

...............................

3-1

0

3. 4

FULL

AUTO

SEM

image

.....................

.

.........

.

•......

3-1

0

3. 5

Photograph

y··.··

......

.

.................•

.

..

.

...

.

...

.

.....

3-

11

3. 5

.1

Photographic

recording

sy

stems

.....................

3-1

1

3. 5

.2

Photog

r

aphing

the

sca

n

nin

g

image

....

.

...

. . .

........

3

-1

4

3. 5. 3

Film

speed

and

f-numb

er

..

......

.

....

.

..

.

...

.

..

.

....

3-

15

3. 5 . 4

Use

of

ultrahigh

speed

Polaroid

Land

sheet

film

(type

107

,

57

,

etc

.)

..

..

..

.

........

.

.............

. . 3-

15

3. 5 . 5

Data

readout

on

micr

ogr aph

.......

.

......

.

..........

3-1

6

3. 6

Aligning

the

mi

c

ros

c

op

e

......

.

...........

.

.....

. .

...

.

..

...

3-18

4.

MAINTENANCE

I

(General

Precautions)

......

.

.......

.

•.......

.

..

. . 4

-1

5.

MAINTENANCE

II (Parts

Replaceme

n

t)

. .

...........

.

.....

..

......

..

. 5

-1

5 . 1

Electron

gun

filament

r

eplacement

.................•.......

5-

1

5 . 2

Removing

the

condense

r l

ens

aper

t

ure

.........

..

...

.

......

. 5- 4

5 . 3

Removing

the

objective

lens

aperture

...

...................

5- 6

5.4

Disassembling

the

beam

deflecto

r . .

........

.

.........

.

..

. . .

5-8

5.5

Replacing

the

scintill

a

tor

........

.

..

..

..............

.

....

5- 9

5 . 6

Replacing

the

oil

diffusion

pump

heater

. .

..

..

.

........

.

...

5-

11

5 . 7

Oil

rotary

pump

maintenance

....

.

..

.

..

.

.........

.

...

...

. .

..

5-12

5.8

Fuse

replacement

....

.

...

. . .

.............

. . .

...

.

..

.

....

....

5-

13

7907001

01

T200