Jesco TOPAX DE User manual

TOPAX®DE

Two-Channel Controller

EN 01 Operating instructions

Read this operating manual before using the equipment.

To be retained for future reference.

2 | BA-40400-02-V14

Two-Channel Controller TOPAX DE

Table of Contents

1 Safety Instructions ............................................................................... 3

1.1 General ................................................................................................ 3

1.2 Identification of safety instructions in the operating manual ..................... 3

1.3 Personnel qualification and training........................................................ 3

1.4 Electrical device safety instructions ........................................................ 3

1.5 Hazards due to non-compliance with the safety instructions .................... 3

1.6 Working in a safety-conscious manner ................................................... 3

1.7 Safety instructions for the operator......................................................... 3

1.8 Safety instructions for installation, maintenance and inspection................ 4

1.9 Modifications and obtaining spare parts ................................................. 4

2 Before using the equipment................................................................. 4

2.1 Use for intended purpose....................................................................... 4

2.2 Scope of delivery .................................................................................. 4

2.3 Steps to take for start-up....................................................................... 4

3 Technical data....................................................................................... 5

3.1 Recommended cables........................................................................... 6

4 Assembly and Installation.................................................................... 7

4.1 General Notes....................................................................................... 7

4.2 Dimensions .......................................................................................... 7

4.3 Wall assembly....................................................................................... 7

4.4 Technical components ........................................................................... 8

4.5 Power connections................................................................................ 9

4.6 TOPAX on the EASYPRO water sampling station.................................... 10

4.7 Terminal clips of the main board and the technical components ............. 11

4.8 Input configuration .............................................................................. 13

4.9 Output configuration............................................................................ 14

4.10 Operation and keyboard layout........................................................... 17

4.11 First set-up and programming guidelines............................................ 17

4.12 Next steps ........................................................................................ 19

5 Measuring values inputs.................................................................... 19

5.1 Measurement input Disinfection (amperometric measurement cells)....... 20

5.2 pH value measurement input ............................................................... 21

5.3 Measurement output Redox potential .................................................. 23

5.4 Temperature measurement input.......................................................... 23

6 Explanation of digital signal inputs ................................................... 24

6.1 Start-up delay..................................................................................... 24

6.2 Deactivation of the controller function with alarm signaling in the case of lack

of sample water........................................................................................ 24

6.3 Low level alert, alarm and warning "level dosing pump" ........................ 24

7 Explanation of measuring values outputs ......................................... 24

7.1 General .............................................................................................. 24

7.2 Output types....................................................................................... 24

7.3 Output restriction ................................................................................ 25

7.4 Actuator ............................................................................................. 25

8 Controller explanation........................................................................ 25

8.1 Definitions .......................................................................................... 25

8.2 Proportional controller (P controller)...................................................... 25

8.3 Proportional-integral-derivative controller (PI, PID controller) .................. 25

8.4 Calculation of setable values................................................................ 26

8.5 Controller parameters.......................................................................... 27

8.6 Control direction ................................................................................. 27

8.7 Basic load dosing................................................................................ 27

8.8 Manual mode ..................................................................................... 27

9 Alarms................................................................................................. 27

9.1 Measurement alarms .......................................................................... 27

9.2 Safety cutout (Y alarm) ....................................................................... 27

10 Analogue power outputs 0/4…20 mA for remote displays .......... 28

11 Log book function............................................................................. 28

12 Menu configuration and main settings............................................ 29

12.1 Menu of TOPAX................................................................................. 29

13 Default settings ................................................................................ 37

14 Memory card..................................................................................... 37

15 Troubleshooting and diagnostics..................................................... 38

15.1 Self-setting alarms............................................................................ 38

15.2 Displays that must be confirmed with "OK"......................................... 38

15.3 Remedy............................................................................................ 38

16 terminal connection diagram for own configurations .................... 39

16.1 measurands .................................................................................... 39

16.2 Output types..................................................................................... 39

17 Device revision ................................................................................. 40

18 Warranty claim.................................................................................. 41

19 EC Declaration of Conformity........................................................... 42

20 Index ................................................................................................. 43

BA-40400-02-V14 | 3

Operating instructions

1 Safety Instructions

1.1 General

This manual contains essential information for the installation, start-up,

operation and maintenance of the equipment. Please have your staff and

any person in charge of the unit read and understand this manual be-

fore starting any work with it. Store this manual safely in a place where

mechanics, installers and other technical staff as well as operators can

rapidly access it in case of emergency. Attention must also be paid to all

the safety instructions in this manual.

1.2 Identification of safety instructions in the operating

manual

This operating manual contains essential safety instructions. Failure to

observe this information may endanger other people and the unit. The

safety instructions are identified by the following symbols:

WARNING!

Refers to a potentially hazardous situation. Failure to follow

this instruction may lead to death or severe injury.

CAUTION!

Refers to a potentially hazardous situation. Failure to fol-

low this instruction may lead to minor injury or damage

to property.

ATTENTION! or NOTICE!

Failure to comply with this safety instruction may result in

damage to the device and endanger its operation.

IMPORTANT!

This refers to additional information to facilitate operation

and ensure the smooth running of the equipment. Appropri-

ate reference attached directly on the unit or any of its other

parts must absolutely be considered and held in completely

readable condition for future reference.

1.3 Personnel qualification and training

Your installation, operation, maintenance and inspection staff must be

trained and qualified for these tasks. Personnel areas of responsibility,

tasks and supervision must be controlled and ensured by the operat-

ing company at all times. Unskilled personnel must be trained and in-

structed. If necessary, this can also be performed by the manufacturer

or certified supplier on behalf of the operating company. The operating

company must also ensure that the operating manual has been under-

stood.

1.4 Electrical device safety instructions

Basic safety precautions should always be followed when installing and

using this electrical equipment. These include the following:

WARNING!

1.) Read and follow all instructions.

2.) To reduce the risk of injury, do not permit children

to use this product unless they are closely super-

vised at all times.

3.) Risk of electric shock. Ensure that the device is

secured with a ground fault - circuit breaker (GFCI

= earth-leakage circuit breaker). Contact a qualified

electrician if you cannot verify whether the connec-

tion is protected by a GFCI.

4.) Do not bury cord. Fix the cable to minimise pos-

sible damage due to lawn mowers, hedge trimmers,

and other equipment.

5.) To reduce the risk of electric shock, replace the

cable immediately if damaged.

6.) To reduce the risk of electric shock, do not use an

extension cable to connect the device to the power

supply; use an appropriately located socket.

7.) Keep these instructions for future reference.

1.5 Hazards due to non-compliance with the safety

instructions

Failure to comply with the safety instructions may endanger not only

people, but also the environment and the unit. Failure to follow the safety

instructions will invalidate any damage claims.

The following hazards in particular may arise: Failure of major func-

tions of the device. - Danger to persons from electrical, mechanical and

chemical influences. Danger to the environment due to leakage of haz-

ardous substances.

1.6 Working in a safety-conscious manner

The safety instructions contained in this operating manual must be ob-

served. The operating company is responsible for ensuring compliance

with local safety regulations. Any faults that could affect safety must be

rectified immediately.

1.7 Safety instructions for the operator

Statutory regulations must be observed. Consumables and replacement

parts must be disposed of safely and in an environmentally friendly man-

ner. Avoid possible hazards from electric current (for further details refer

to section 1.4).

4 | BA-40400-02-V14

Two-Channel Controller TOPAX DE

1.8 Safety instructions for installation, maintenance and

inspection

The operating company must ensure that all installation, maintenance

and inspection work is carried out by qualified and authorised personnel.

WARNING!

Installation and maintenance work on the equip-

ment must only be carried out after the de-

vice has been disconnected from the power

supply. The device must be prevented from

being switched on again during the above work.

Auxiliary modules should be fitted/removed in this

condition. Cables should also only be attached in this

condition.

ATTENTION!

Before opening the device, ensure that it cannot suf-

fer damage through electrostatic discharge. The fit-

ter is to perform all necessary measures to this end

(e.g. touch a metal conductor which is grounded).

Use ESD-compliant, conducting tools when chang-

ing electronics components and connecting the ca-

ble. Wherever possible, avoid contact with electronic

components with bare hands or uninsulated tools.

Neglecting of these instructions can lead to severe damages of

TOPAX and loss of warranty.

All safety mechanisms and guards must be refitted and reactivated as

soon as the work is completed.

ATTENTION!

As well as faulty installation, incorrect controller set-

tings (setpoint, parameter and configuration level

data, and device-internal modifications) can impair

the process or result in damage.

There should always be a safety device independent of the controller.

Configurations may only be carried out by technical personnel! If neces-

sary use password protection. Always comply with the safety regulations

of the country of use.

1.9 Modifications and obtaining spare parts

TOPAX may be converted or changed only by qualified technical person-

nel.

If the configuration of the TOPAX is wrongly made by assembly or ser-

vice personnel, errors and dangers in the function of the machine can

result. In this case, the manufacturer declines any liability.

ATTENTION!

Only genuine manufacturer spare parts and sensors

may be used. Failure to comply will invalidate the

warranty.

2 Before using the equipment

2.1 Use for intended purpose

The TOPAX is exclusively designed and meant for metering and control

applications in water treatment plants and waste water management.

The operational safety of the unit can only be ensured if used according

to its purpose.

All other types of use are prohibited and will invalidate the warranty.

2.2 Scope of delivery

Carefully check the delivery prior to installation and refer to the delivery

note to ensure the delivery is complete and to check for any transport

damage. Contact the supplier and/or carrier regarding any questions

concerning the delivery and/or transport damage.

Do not operate defective devices.

The scope of delivery includes:

• TOPAX casing (as per the model)

• Tool (M4 screw) to open the casing

• Memory card

• Mounting material

• Operating instructions

• Measuring protocol

• Terminal plan for the sensors

• Electrodes (optional)

• Cable connection TOPAX to the electrodes (optional)

The device is delivered either as detached or mounted onto a measuring

water table.

2.3 Steps to take for start-up

The following steps are recommended by the manufacturer in order to

install the TOPAX successfully:

• Reading the operating instructions

• Installing the device

• Attach the sensors and actuating element (to the controlling

pumps and switch, etc.)

• Calibrate the sensors to the measuring output

• Adjusting the input measuring ranges

• Controller explanation

• Configuration of the regulating output

BA-40400-02-V14 | 5

Operating instructions

3 Technical data

Supply voltage 90 … 264 V AC, 47 … 63 Hz

Power consumption Approx. 24 W

Housing dimensions 302 x 231 x 108mm (W x H x D) wall-mounted housing

Display Graphic colour display 5.7 inch, 320 * 240 pixels (RGB), with LED backlight (lighting dims automatically after 10 minutes)

Keyboard Keyboard with touch keys

Measurement inputs

(potential-free)

Inputs for disinfection, pH value, REDOX potential, temperature

Control characteristic for 2 inputs

(disinfection, pH value)

P, PI, PD or PID performances

Fixed value regulation, standard channel selectable with disturbance variable feed forward

2-side controller

Control parameters Xp: 1…500%, Tn: 1…200 minutes, Tv: 1...1200 seconds

Measurement input Disinfection Open amperimetric electrode with mechanical cleaning (excess chlorine detector with 2 electrodes, CS 120)

Measuring range adjustable from: 0-1,00 mg/l, 0-2,00 mg/l, 0-5,00 mg/l oder 0-10,00 mg/l. Connection via series terminals*

Potentiostat (PM)

Measuring range adjustable from: 0-1,00 mg/l or 0-2,00 mg/l

Encapsulated electrode 20 mA type with supply of the measuring cell (24 VDC), measuring range depending on

measuring cells

Measuring range adjustable from:

0 – 1,00 mg/l, 0 – 2,00 mg/l or 0 – 10,00 mg/l

Measuring input for pH value Measuring range pH 0 … 14 Connection via series terminals*

REDOX potential measuring input

(for disinfection)

Measuring range

0...1000mV

Connection via series terminals*

Temperature measuring input - Pt

100

Measuring range

-10°C…+100°C

Two-leader connection by means of line-up terminals*

Total chlorine measuring input Encapsulated electrode Measuring range adjustable from:

0 – -1,00 mg/l, 0 – 2,00 mg/l or 0 – 10 mg/l

Disturbance variable input (option-

ally available)

0...20 mA or 4...20 mA

Disturbance factor: 0.1 … 10 times amplification

Digital inputs - Low level alert input for metering pump 1

- Alarm level input for metering pump 1

- Low level alert input for metering pump 2

- Alarm level input for metering pump 2

- Measuring water shortage disconnection of the regulating function with alarm (external switch off)

Controller outputs Electronic output

(optocouplers)

- 48 V DC; 250 mA

(Pulse frequency 10 … 350 Impulses/min)

Relay output - ON/OFF

- Pulse frequency 10 … 100 Impulses/min

- Pulse length 10 … 3600 seconds

- 3-point step output with

- Position feedback

value of the Potentiometer 1 … 10 kOhm

Continuous output 0/4…20 mA, max. load 500 ohms

Alarm output Relay output as collective alarm for the measuring size of Disinfection, pH value, redox potential, temperature and conductivity as

potential free changer

Measurement alarm Min. and max. alarm freely adjustable, time delay adjustable: max. 200 min

Safety cutout To prevent over metering (Y-alarm), time delay adjustable: max. 200 minutes

Current outputs for remote trans-

mission of measuring values

- Disinfection

- pH value

- Redox potential

- Temperature

0/4 … 20 mA possible spreading; max. load 500 ohms potential free

Useful spreading >50% with measuring input Disinfection and 0/4...20mA

>10% during measurement input of pH-value and redox potential

Computer interface (optional) RS 485

Load capacity of the relay 230VAC, 3A

Protection class IP65 with locked screw connections

Ambient temperature -5°C … +45°C

Air humidity 95% non-condensing

*) max. 0.5mm² with cable end sleeve and max. 1.0mm² without cable end sleeve.

6 | BA-40400-02-V14

Two-Channel Controller TOPAX DE

3.1 Recommended cables

Recommended cables for the different connections and applications:

Connections and applications Dimensions Types

Mains voltage M20 X 1.5 NYM-I 3 x 1.5 mm (9.1 mm)

Relay output (ATE- engine) M20 X 1.5 NYM-I 4 x 1.5 mm (9.8 mm)

Relay output (pulse frequency), (pulse length) M16 X 1.5 NYM- O 2x 1.5 mm ( 8.7 mm)

Relay output alarm) M16 X 1.5 NYM- O 3x 1.5 mm ( 9.1 mm)

connection to PC, computer cable Cat 5 M12 X 1.5 Type 2X2XAWG24/1 ( 5.7 mm)

Connection of current outputs (remote communication cable) M12 X 1.5 J-Y (St) Y 4 x2x0,6 mm ( 6.5 mm)

Position feedback ATE- engine (remote communication cable) M12 X 1.5 J-Y (St) Y 2x2x0.6 mm ( 5.0 mm)

Continuous controller output (remote communication cable) M12 X 1.5 J-Y (St) Y 2x2x0.6 mm ( 5.0 mm)

Input measuring cell M12 X 1.5 LIYY 2x 0.25 mm

Digital inputs (for each input) (remote communication cable) M12 X 1.5 J-Y (St) Y 2x2x0.6 mm ( 5.0 mm)

BA-40400-02-V14 | 7

Operating instructions

4 Assembly and Installation

4.1 General Notes

For installation, the local directions and regulations have to be adhered

to. Any mounting position is possible. The ambient conditions are to be

maintained in accordance with the technical data. Exposure of the unit

to direct heat and sunlight must be avoided.

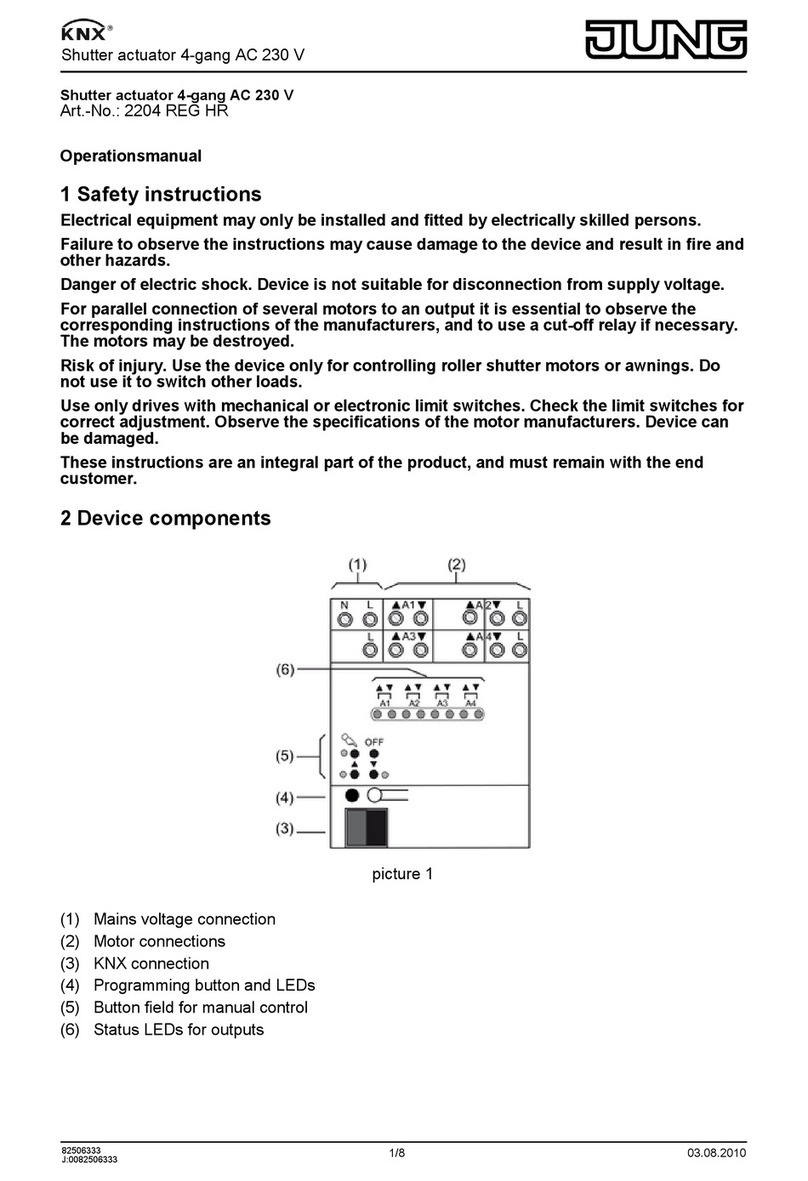

4.1.1 Diagram TOPAX housing

The TOPAX device is composed of two parts, a rear and a front housing.

The rear shell of the housing is electrically connected with a flat cable

with the front one.

The front housing aand the rear housing bof the controller are fitted

together with two pivots (cand d). The unit is designed so that the

controller can be opened from either side.

db

c

a

⑤

f

aFront housing

bRear housing

cHinge pivot (fitted)

dHinge pivot (disassembled)

⑤Pivot head (unscrewed)

fPivot disassembly tool

4.1.2 Opening the housing

To open the housing it is preferable to remove the right pivot. To do this,

unscrew head ⑤of the pivot. The pivot disassembly tool fserves the

purpose.

ATTENTION!

In order to open the housing remove only one pivot

from the equipment. If both pivots are removed at

the same time, the front housing will no longer be

attached to the bottom section.

ATTENTION!

The equipment must only be opened when it is dis-

connected from the power supply.

4.2 Dimensions

Fig.1: Dimensions TOPAX

4.3 Wall assembly

For the wall assembly 4 mounting holes are to be found in the lower part

of the housing. The hardware for wall fixation is provided with the unit

by the manufacturer.

171 mm

267 mm

Fig.2: Spacing of hole for mounting the device

4.3.1 Rear housing

consists of rear housing with the motherboard, in which the cable con-

nections are screwed in.

On the motherboard there are the main modules for the functioning.

Depending upon the model, two input assemblies are available together

with one output assembly. For networking purposes with connection to

a PC, an additional interface (RS485) is available. All assemblies are at-

tached to the main board by plug connectors and fastened with several

nuts.

4.3.2 Front housing

The front housing contains the display board and the keyboard. A colour

display is included to show measurements and allow for adjustment. The

operation takes place with 6 function keys as well as a control cross with

"OK" key. The keys are integrated in a keyboard and react to contact. All

displays of the individual menus appear as plain text.

302 mm

240 mm

8 | BA-40400-02-V14

Two-Channel Controller TOPAX DE

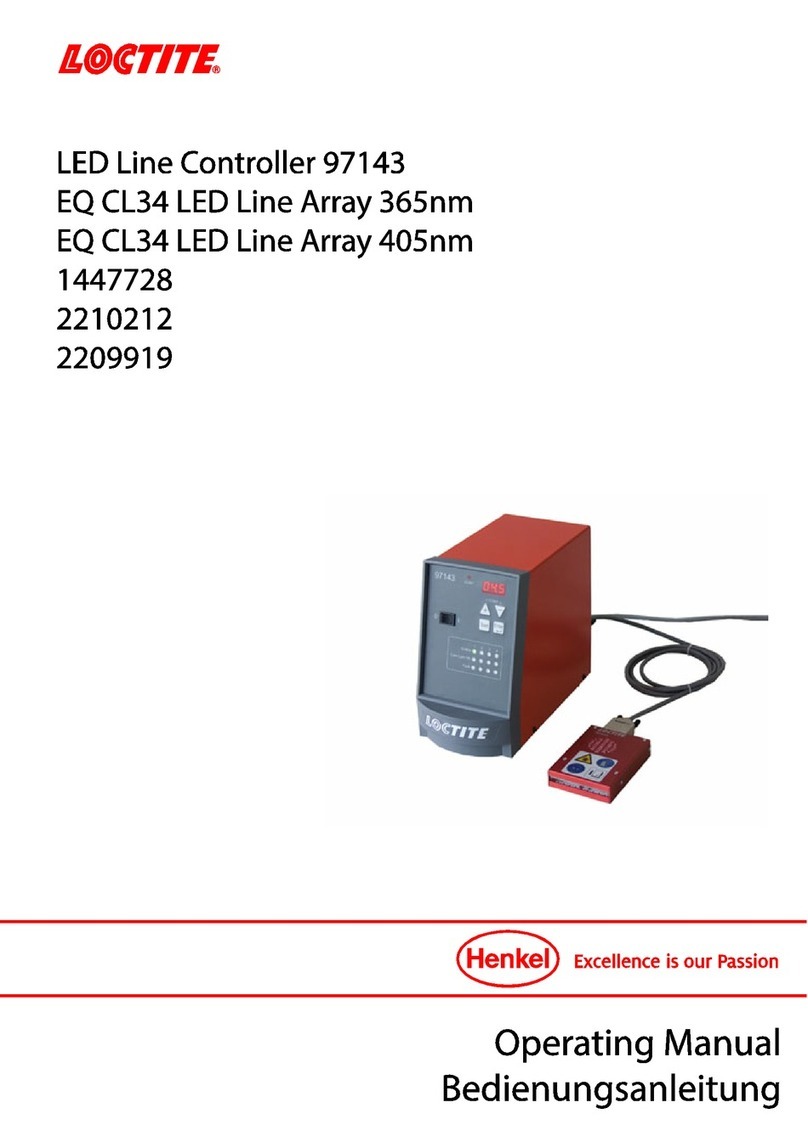

4.4 Technical components

Besides the main board, the following can be fitted in addition

• up to 2 input components

• an output component and

• an Interface module (RS 485)

To operate the TOPAX at least one entry component has to be built in.

output block

mainboard

DO4 DO3 DO2 DO1

DO7 DO6 DO5

DO0

PC interface RS 485

+-

+-+-+-+-+-+-+-

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

20 mA Power Outputs Digital Outputs

36

37

38

PE

N

L

power generator

33

34

92

93

94

87

88

89

90

91

86

-+

81

82

83

84

85

- -+ +

56

57

58

59

60

-+

51A

52A

53

54

55

61

51B

52B

- -+ +

-

+

71

72

73

74

75

76

77

78

5-fold input block

Alarm relays

39

40

41

43

44

45

46

42

35

95

96

B

A

3-fold

input block

Plugin connector

to the display circuit board

Fig.3: Arranging the components on the main board

4.4.1 Main board

Besides this function, to incorporate the further components, the main

board is made up of the following connections:

• 5 analogue power inputs (0/4 … 20mA)

• 5 digital inputs

• Alarm relay

• power supply

4.4.2 5-fold Input block

with 5 measurement inputs for:

• Dinsinfection (single amperimetric electrode or encapsulated

electrode) (0/4...20 mA)

• pH single-rod measuring cell

• Redox single-rod measuring cell

• Temperature sensor Pt100

• Position feedback of a servo motor with potentiometer

4.4.3 3-fold Input block

with 3 measurement inputs for:

• Disinfection (potentiostatic measuring cell)

• Position feedback of a servo motor with potentiometer

• 0/4 20 mA power entrance for the connection of a disturbance

variable

4.4.4 Output board

On the output block there are 5 integrated relay output and 3 electronic

outputs (optocouplers).

The following output can be configured:

• Control output Disinfection

with various output functions

• Control output pH-value

with various output functions

The software configuration automatically assigns these outputs to the

respective terminals in a sequential order- depending on the configura-

tion of the TOPAX:

1. Disinfection controller

2. Controller pH value

Depending upon output type, TOPAX selects the next free relay output or

optocoupler. The clamps are assigned in a firm order: clamps 87/88 to

95/96 for relays, or 81/82 bis 85/86 for optocouplers.

NOTE!

For further information on the terminal connection,

refer to section “4.7 Terminal clips of the main board

and the technical components” on page 11.

4.4.5 Interface board RS 485

The TOPAX has the option of being fitted with a serial interface RS 485.

The RS 485 allows you to transfer data to a PC. The MODBUS protocol

serves as data transmission protocol.

With the RS 485 interface it is possible to connect more than one TOPAX

to a network. For this an address is to be assigned to each TOPAX. In

addition to this each TOPAX is fitted with a computer-interface RS 485.

It is possible to have a maximum of 1000 m of data transfer with the

RS 485 interface. Up to 14 TOPAXs can be connected to a network with

a PC.

ATTENTION!

The data line is to be attached direct to the con-

necting terminals of the TOPAX (clip A and B, see

Fig.4). Separate external connection or distribution

boxes must not be set. The network address 10 is

not permitted.

IMPORTANT!

For the realization of a network with the TOPAX and

the structure of a bus system to a PC a computer

cable "KAT.5 type 2X2XAWG24/1 (Lapp cable)" or

better is to be used. Using other cables can cause

data errors and affect the data transmission. The

manufacturer is not liable for this.

Most modern computers are equipped with the serial computer interface

R-S 232 and/or with USB - interfaces. For the connection to a RS 485

network, an additional connector converter (RS 485 to RS 232 or RS

485 to USB) is necessary.

There are interface components in the under casing part of the main

board in the TOPAX. It is partially hidden from view by the output module.

BA-40400-02-V14 | 9

Operating instructions

Fig.4: RS 485 connections on the interface module board, partially obscured by

the output module

CAUTION!

The data line must be locked at both sides with a

120 Ohm line resistance and must be supplied a

firm potential using the two link plugs on the two

jumpers on the circuit board of the display of all la-

test TOPAX versions.

Two link plugs/jumpers have to be connected to the TOPAX (the last one

in the network) for the 120 ohm switch, Pull-up and Pull-down resist-

ances. The resistances are not active when the system is delivered. The

resistance of 120 ohms on the PC side is applied via the connector

converter.

The jumper slots are located in the front of the housing on the display

board, above the flat band-connection to the main board.

Resistors deactivated

(delivery status)

Resistors activated

(last device in the network)

Jumper position: OFF Jumper position: ON

The resistors are NOT active.

The jumpers are set DOWN

The resistors are activated.

The jumpers are set UP

Fig.5: Position and setting of the jumper to activate the RS 485 resistances on

the last TOPAX in the network.

4.4.6 TopView software

For remote viewing on a PC the manufacturer offers the full version of

the TopView display program and a freeware version with limited func-

tionality. The "TopView mini" freeware version is free on the internet and

can be downloaded from the manufacturer's website.

4.5 Power connections

The equipment may be installed and attached only by authorized and

qualified electricians. Connections must be made according to the en-

closed wiring diagrams.

ATTENTION!

Only work on electrical connections while the device

is disconnected from the power supply.

Insert the cables in the various connections screwed on the bottom side

of the housing. After the installation, tighten all cable connections so

that the required protection class is provided.

Fig.6: Cable connections for protected cable passage to the rear part of the

housing.

For the connection to the power supply and to the actuators, TOPAX is

equipped with special terminal clips.

Fig.7: The principle of the connecting terminal to the technical components.

For a better assembly these clamps are designed plug-ins, whereby the

maximum cross section is 2.5 mm2for the power cord and 1.5 mm2for

all other cable to the terminal clips.

10 | BA-40400-02-V14

Two-Channel Controller TOPAX DE

Fig.8: Individual connecting terminals, removable for installation, of the technical

components.

ATTENTION!

When choosing the line material, for installation and

electrical connection of the device, observe the regu-

lations of VDE 0100 “Provisions for setting up elec-

tric power plants with nominal voltages below 1000

V“ or the individual national rules.

ATTENTION!

The equipment is not suitable for the installation in

explosive conditions!

4.5.1 Connection of the in- and outputs

NOTICE!

Terminal clips allocation depends on the software

configuration of TOPAX. Terminal clips allocation de-

pends on the delivered equipment.

The delivered equipment is listed in the protocol, which is attached to

the device. Use this terminal plan to wire the device and to put it in

operation.

4.5.2 Voltage supply

This instrument has no power switch and is immediately operative after

the creation of the operating voltage. For this reason an external switch

and/or protective switch is to be planned.

For the connection to the power supply at the main board, refer to the

enclosed terminal plan (see “4.7 Terminal clips of the main board and

the technical components” on page 11).

ATTENTION!

DO NOT let power be switched on via timer opera-

tion!

4.5.3 Sensor technology

Measuring cables may not be parallel when too close (less than 15 cm)

to power switches and/or cables for power installation. Separate cable

channels are to be used. Disturbing stray effects could otherwise falsify

the measurement. Power supply and measuring lines at close proximity

should only cross at a 90° angle.

The maximum permissible length of the measuring cables depends on

the kind of the sensor. When performing very ohmic measurements (e.g.

pH or REDOX measurements) the following is to be considered:

• Connections and patch cords must be clean and dry.

• The permissible bending radius of the cable must be respected.

• The quality of the holding wires must correspond to the defaults

from the data sheet of the sensor.

IMPORTANT!

If possible a continuous cable is to be used from the

sensor to the measuring entrance. An extension of

the cable by plugs or terminal socket increases the

risk of disturbances due to contamination, humidity

or excessive transition resistances.

4.5.4 Connecting the actuators

When connecting your actuator the equipment must be switched off to

prevent uncontrolled starting and malfunctioning.

WARNING!

If devices e.g. dosing pumps with inductive loads

from a nominal current of 1 A are connected to

a relay, the contacts in the relay may be bonded.

Thus, the device will operate in an uncontrolled

manner. This may also result in an overdosing of

chemicals. To prevent the output relays from bond-

ing if the load circuit shorts, they must be protected

separately on the maximum relay switching current.

For inductive loads, protective circuit must be ap-

plied to the relay contacts (spark suppression). The

manufacturer recommends the use of the interfer-

ence suppression module / spark suppression de-

vice (article 78614).

4.5.5 Replacing the batteries

The life of the batteries (Type VARTA, CR1/2 AA, 2 Volt, Lithium) provided

with the internal instrument clock is approx. 5 – 10 years. When the bat-

teries wear out causing a power shortage, a warn-ing message will be

displayed on the instrument. The battery is welded on the display circuit

board. It must be replaced by a skilled technician.

Fig.9: Battery for internal clock, on the display circuit board.

4.6 TOPAX on the EASYPRO water sampling station

If the TOPAX is set up on an EASYPRO water sampling station, it controls

the illumination of the LEDs. The LEDs of the sensors are controlled via

the measured values. The LEDs illuminate green when the measured

values lie within the set range. Leaving these ranges causes the LEDs

to illuminate red.

TThe DIN contact must be activated in the control.

BA-40400-02-V14 | 11

Operating instructions

4.7 Terminal clips of the main board and the technical

components

output block

mainboard

DO4 DO3 DO2 DO1

DO7 DO6 DO5

DO0

+-

+-

+-+-+-+-+-+-

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

20 mA Power Outputs Digital Outputs

36

37

38

PE

N

L

power generator

33

34

92

93

94

87

88

89

90

91

86

-+

81

82

83

84

85

- -+ +

56

57

58

59

60

-+

51A

52A

53

54

55

61

51B

52B

- -+ +

-

+

71

72

73

74

75

76

77

78

5-fold input block

Alarm relays

39

40

41

43

44

45

46

42

35

95

96

B

A

3-fold

input block

Plugin connector

to the display circuit board

Fig.10: Rear part of the housing with the main board, the input module 5-fold,

the input module 3-fold, the output module and the partly hidden PC interface.

4.7.1 Main board

Terminal Function

Analogue power outputs 0/4...20 mA (also see chapter 11)

1 + Measurement output

0/4...20mA

Disinfection

2 -

3 + Measurement output

0/4...20mA

pH value

4 -

5 + Measurement output

0/4...20mA

Redox

6 -

7 + Measurement output

0/4...20mA

Temperature or programmed as

controller output

8 -

9 + Measurement output

0/4...20mA

combined chlorine or programmed

as controller output

10 -

11 + Measurement output

0/4...20mA

conductivity or programmed as

controller output

12 -

13 + Continuous control

output

0/4...20mA

programmed as controller output

14 -

15 + Continuous control

output

0/4...20mA

programmed as controller output

16 -

ATTENTION!

The constant regulating outputs 0/40 ... 20 mA of

the main board are also allocated automatically in

the software configuration as per a fixed rank order

of the terminals, in accordance with the allocation

procedure for the output components.

Ranking of the outputs for automatic allocation:

1. Control output Disinfection

2. Control output pH value

3. Controller output for combined chlorine

4. Controller output for conductivity

5. Flocculation pump output

In the same way the clamps are assigned in a firm order.

• Terminals 15/16

• Terminals 13/14

• Terminals 11/12

• Terminals 9/10

• Terminals 7/8

The clip allocation is automatically displayed at the end of the configura-

tion.

12 | BA-40400-02-V14

Two-Channel Controller TOPAX DE

Terminal Function

Digital inputs

17 potential free input measuring water shortage *)

18

19 potential free input filter cleaning *)

20

21 potential free input low level alert Controller 1 **)

22

23 potential free input level alarm Controller 1 **)

24

25 potential free input low level alert Controller 2 **)

26

27 potential free input level alarm Controller 2 **)

28

29 potential free input activate night mode operation

30

31 potential free input not used

32

*) normally ON or normally OFF

**) normally ON or normally OFF or not active

33 A internal

PC interface

interface for software updates

34 B

35 GND

36 alarm relay as common

alarm

Opener

37 middle contact

38 Closer

39 PE protective conductor Voltage: 90 up to 264 V AC

40 PE

41 N neutral conductor

42 N

43 N

44 L phase

45 L

46 L

4.7.2 Input module (5x)

Terminal Function Cable colour Comment

51A + Disinfection

(amperometric

measuring cell type

CS 120)

Electrode mating

copper/platinum

or silver/platinum

possible

CS 120 (Cu/Pt)

Cu/ : blue (-)

Pt/ : red (+)

CS 120 (Ag/Pt)

Ag/ : purple(-)

Pt/ : red (+)

variant A and

variant B can be

only used as an

alternative

52A -

51B + - total chlorine measuring cell

(4...20mA)

- membrane covered cell

Disinfection (0/4...20 mA)

(20 mA input with 24 V DC sensor

power)

52B -

53 + pH value

54 -

55 + Redox

56 -

57 Temperature

(polarity at wish)

58

59 potentiometer with positional feedback for servo motor

(polarity of clips 59 and 61 at wish)

60 Driver

61

4.7.3 Input module (3x)

Terminal Function Cable colour

71 Reference electrode

(with integrated cable)

Disinfection

(potentiostatic

measuring

cell)

Reference electrode

(Glass): black

Counter electrode (Stain-

less steel): red

Measuring electrode (gold):

purple

72 Counter electrode

Stainless steel

73 Measuring electrode

(gold)

74 + 20 mA passive (no supply to the sensor)

- conductivity measurement or disturbance

variable

75 -

76 Potentiometer with positional feedback for

Servo motor. (polarity of clips 76 and 78

at wish)

77 Driver

78

4.7.4 Output module

Termi-

nal

Output

81 + Electronic output (DO7) (Optocoupler) configurable

82 -

83 + Electronic output (DO6) (Optocoupler) configurable

84 -

85 not available

86

87 Relay output (DO 4) configurable

88

89 Relay output (DO 3) configurable

90

91 Relay output (DO 2) configurable

92

93 Relay output (DO 1) configurable

94

95 Relay output (DO 0) configurable

96

ATTENTION!

The constant regulating outputs 0/40-20 mA of the

output components are also allocated automatically

in the software configuration as per a fixed rank or-

der of the terminals, in accordance with the alloca-

tion procedure for the main board.

The outputs are allocated according to ranking:

1. Disinfection controller

2. Controller pH value

3. Controller combined chlorine

4. Controller conductivity

5. DIN contact

6. Eco-contact

7. Flocculation contact

Depending upon output type, chloriDES selects the next free relay output

or optocoupler. The clamps are assigned in a firm order: clamps 87/88

to 95/96 for relays, or 81/82 to 83/84 for optocouplers.

BA-40400-02-V14 | 13

Operating instructions

4.8 Input configuration

No. Article name Function Terminal

1 Conductivity Transmitter and Measuring Cell 20/60 mS/cm Conductivity 74 + 75

2 Diaphragm-covered Measuring Cell Type CD 4 MA Chlorine dioxide 51B + 52B

3 Diaphragm-covered Sensor 4...20 mA Type Cl 4.1 A 2 Free chlorine 51B + 52B

4 Disturbance variable 4-20 mA Disturbance variable* 74 + 75

5 Measuring Cell for Total Chlorine Total chlorine 51B + 52B

6 Measuring Electrode for Disinfection Measuring, Reference Electrode for Disinfection Measuring Free chlorine 71 + 72 + 73

7 pH Single-Rod Measuring Cell PE110 pH 52 + 53

8 Redox Single-Rod Measuring Cell ME110 ORP 54 + 55

9 Reference Electrode for Potentiostat; SS Electrode for Potentiostat 1.4571; Gold Electrode for Potentiostat Free chlorine 71 + 72 + 73

10 Residual Chlorine Measuring Cell CS120 Free chlorine 51A + 52A

11 Resistance Thermometer TE 110, PT100 Temperatur 56 + 57

Overview

56

57

58

59

60

-+

51A

52A

53

54

55

61

51B

52B

- -+ +

-

+

71

72

73

74

75

76

77

78

Sliding contact

Measuring Cell for Total Chlorine (Pos. 5),

4...20 mA Typ Cl 4.1 A 2 (Pos. 3)

or

CD 4 MA (Pos. 2)

CS 120 (Pos. 10)

+ = red

- = blue/violet

PE 110 (Pos. 7)

ME 110 (Pos. 8)

TE 110, PT 100 (Pos. 11)

Disinfection (Pos. 6)

or

Potentiostat (Pos. 9)

Conductivity (Pos. 1)

or

Disturbance variable 4...20 mA (Pos. 4)

Feedback

servomotor

Feedback

servomotor

14 | BA-40400-02-V14

Two-Channel Controller TOPAX DE

4.9 Output configuration

No. Article name Output Configuration Signal type Terminal

1 C7700 20mA Current output Current output (20mA) analogue

See TOPAX menu configuration 0.6.3

2 C7700 3-p-s Relay (3 step) 3 point step with poti digital

3 EASYZON D/Da Current output Current output (20mA) analogue

4 MAGDOS DE, DX, LT, LDp, LD, LK, LP Opto coupler output Impulsefrequency (opto) digital

5 MAGDOS LA, LP, DX Current output Current output (20mA) analogue

6 MAGDOS LB bis 2018 Relay (with power relay*) On/off digital

7 MAGDOS LDp, LD, LK, LP, LB ab 2018 Relay On/off digital

8 MEMDOS DX, LA, LP Current output Current output (20mA) analogue

9 MEMDOS DX, LP Opto coupler output Impulsefrequency (opto) digital

10 MEMDOS E, LB Relay (with motor protection*) On/off digital

11 MEMDOS SMART LB, LD, LK, LP Relaisausgang On/off digital

12 MEMDOS SMART LD, LK, LP Opto coupler output Impulsefrequency (opto) digital

13 MEMDOS SMART LP Current output Current output (20mA) analogue

14 MIDIDOS E Relay (with motor protection*) On/off digital

15 MINIDOS A Relay (with motor protection*) On/off digital

16 Peristaltic pump Relay (with motor protection*) Impulselength (relais) digital

17 Technoline SC Relay Impulselength (relais), min. 300s digital

18 Technoline SC Relay On/off digital

19 Technomat PS Relay Impulselength (relais), min. 300s digital

20 Technomat PS Relay On/off digital

21 Technostar 2000 AT Current output Current output (20mA) analogue

22 Technostar ST-30 Current output Current output (20mA) analogue

* accessories

Menu configuration 0.6.3

DANGER!

Open the housing of the TOPAX controller with disconnected power supply only! Secure the power supply to prevent it from

being switched on again.

The assignment of the output terminals depends on the connected devices and their configuration. The required terminals are shown in the menu 0.6.3.

The following steps will take you in that menu.

Precondition for action:

• The TOPAX controller has been successfully installed in accordance with section “4.5 Electrical installation” on page 9.

• The TOPAX controller is disconnected from the power supply.

• The housing of the TOPAX controller is closed.

Perform the following steps:

1. Establish the power supply of the TOPAX controller.

2. Wait until the device is booted.

3. Now press the following keys to get to the configuration menu:

• „OK“,

• „menu 2“,

• „service“,

• „OK“,

• „edit“.

4. Now you are able to change the configuration of the different input and output terminals. Choose the configuration of the output terminals appropiate

to the table above and confirm each entry with „next“ until you reached menu 0.5.

5. Press „save“ and confirm with „OK“. Now you can see the new configuration and the required terminals.

6. Press „next“ until you reached menu 0.6.3. Now you see the output terminals you have to connect your devices with. Note the numbers of the required

terminals.

7. Press „next“ and confirm with „OK“.

8. Disconnect the power supply of the TOPAX controller, open the housing and connect your devices to the required terminals.

9. Check the correct control of your devices and make corrections if necessary.

The TOPAX controller can now control the connected devices.

BA-40400-02-V14 | 15

Operating instructions

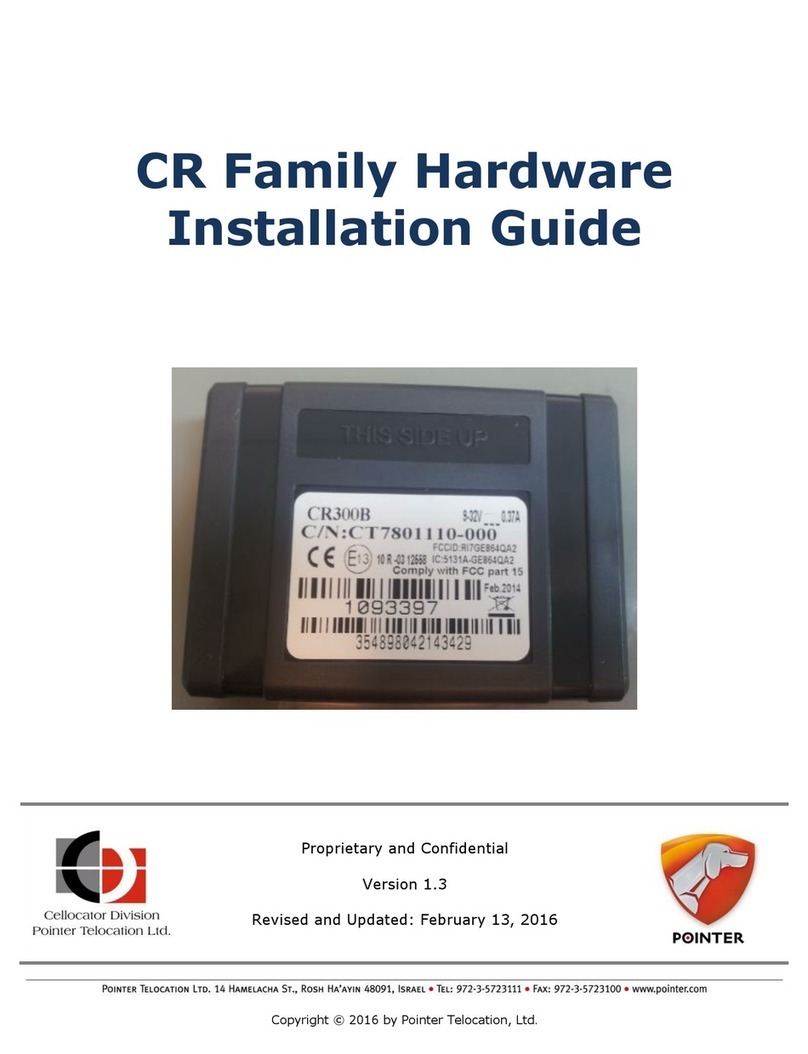

4.9.1 Installation example with C 7700

Sensors connection

Disinfection: Potentialstatic electrode

pH value: Single-rod measuring cell

Redox: Single-rod measuring cell

DO4 DO3 DO2 DO1

DO7 DO6 DO5

DO0

C7700

2 31

11 10 12

+-

+-+-+-+-+-+-+-

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

36

37

38

PE

N

L

33

34

92

93

94

87

88

89

90

91

86

-+

81

82

83

84

85

- -+ +

56

57

58

59

60

-+

51A

52A

53

54

55

61

51B

52B

- -+ +

-

+

71

72

73

74

75

76

77

78

39

40

41

43

44

45

46

42

35

95

96

A

B

A

B

pH value dosing pump

PC interface

Temperature

pH value

Redox

90 - 264 V AC

Input module 5-fold

CPRT(ATE) 5-fold

Power supply unit

Output components

Digital inputs

20 mA power outputs

Main board

Disinfection (potentiostat):

Reference electrode

Measuring electrode (gold)

Counter electrode (steel)

Measuring water shortage

Alarm relay

CLOSED

OPEN

Input module

3-fold

C(P) 20 mA (ATE)

RS 485

Controller connection

Disinfection: C 7700 (servo motor with potentiometer)

pH value: Solenoid-driven dosing pumps

(Pulse frequency optocoupler)

Other: Connection of PC interface RS 485

16 | BA-40400-02-V14

Two-Channel Controller TOPAX DE

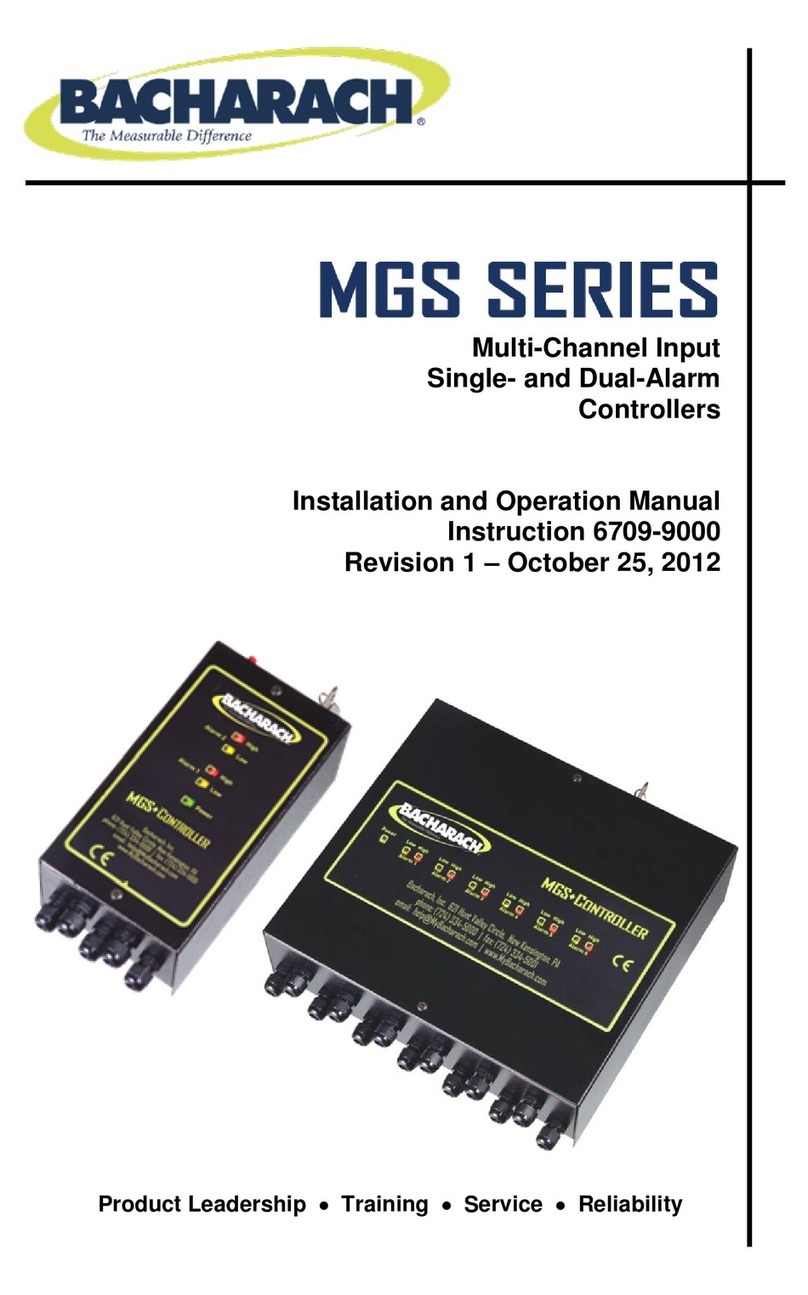

4.9.2 Installation example with peristaltic pumps

Controller connection

Disinfection: Peristaltic pump

pH value: Peristaltic pump

+-

+-

+-+-+-+-+-+-

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

36

37

38

PE

N

L

33

34

92

93

94

87

88

89

90

91

86

-+

81

82

83

84

85

- -+ +

56

57

58

59

60

-+

51A

52A

53

54

55

61

51B

52B

- -+ +

-

+

71

72

73

74

75

76

77

78

39

40

41

43

44

45

46

42

35

95

96

20 mA power outputs

Input module 5-fold

CPRT(ATE) 5-fold

Input module

3-fold

C(P) 20 mA (ATE

Power supply unit

Output components

Digital inputs Alarm relay

90 - 264 V AC

Suppressors

BA-40400-02-V14 | 17

Operating instructions

4.10 Operation and keyboard layout

171 mm

267 mm 302 mm

240 mm

a

b

c

d

⑤

f

Fig.11: Housing of the TOPAX with operating panel.

Keys Functions

Arrow key cross

• Menu change in the "Service" menu

• Change between individual numbers

• Change numerical values, adjust parameters

Press the key to change from one menu item to

the other. Numeric values are entered and modi-

fied continuously.

"OK" key between the

arrow keys

Accept and store inputs

Saving is confirmed by a long beep noise.

Key a: „ESC“ Exit the menu, one level back

Terminate input without saving

Key a: „ESC“

(press down for 5

seconds)

Return to the main menu

Keys b- fThe functions of the keys vary according to the

menu and are displayed respectively.

If the device is not operated for approx. five minutes, the controller re-

turns automatically to measuring mode. Changed parameters not con-

firmed with the “OK” key are not saved.

Exception: this time restriction does not apply during calibration and

configuration.

NOTICE!

If no values or settings are to be changed,

press "ESC" to exit the selected menus at any

time. The controller uses the inital settings.

Values and settings are confirmed

and saved with the "OK" button.

The exception to this rule are the "clock" and "timer"

functions. They can be modified without confirma-

tion.

General input rules:

• All values can only be changed within the permissible range.

• Some functions can be protected by a password against unauthor-

ized access (see “12.1.23 Menus 5.9 and 5.10: Code und service

password” on page 35).

4.11 First set-up and programming guidelines

After correct installation, switch on the power supply.

The TOPAX is programmed by the manufacturer based on customers’

specs before shipment and is supplied along with a terminal connection

diagram.

IMPORTANT!

All menus of TOPAX are shown a ID-number marked

in the bottom line on the left display corner.

4.11.1 Backlight

The backlight of the chloriDES controller is dimmed automatically after

10 minutes and a blue LED under the arrow key cross is lit.

Once any key is pressed, the LED goes out and the backlight turns on

again.

4.11.2 Choice of Language

After a short hardware test the during the initial start-up, the TOPAX

displays the home page for configuration. This screen is shown until a

language has been chosen by pressing the key b(German), c(Eng-

lish), ⑤(French) or f(further languages “>>”).

Deutsch

English

Francais

0.1 Software Version: ...........

Fig.12: Home page for the configuration of language choice

4.11.3 Further languages - Memory card

Besides the fixed installed languages of German and English there

is other language data for the TOPAX. These may be loaded from a

memory card.

The memory card with the language data is inserted on the display

board in the upper casing.

4.11.4 Help-Menu

The Help Menu is available as a point of help for many menu points. By

pressing a random key the TOPAX returns to the previous menu again.

4.11.5 Menu 0.4.1: Input Disinfection

The disinfection connection will be pre-configured according to the or-

der and cannot be changed.

The following options are possible:

• 2-electrodes measuring cell CS 120

• Potentiostat (PM)

• Encapsulated electrode

• Redox single-rod measuring cell

• Total chlorine measuring cell

The selected option is highlighted in grey.

18 | BA-40400-02-V14

Two-Channel Controller TOPAX DE

4.11.6 Menu 0.4.2: Output Disinfection

With the arrow keys▲and ▼you can select between the options:

• Servomotor with potentiometer

• Servomotor without potentiometer

• Pulse frequency (Optocoupler)

• Pulse frequency (relay)

• Pulse length (relay)

• Continuous control output (20 mA)

• ON/OFF (relay)

• No controller function

The selected option is highlighted in grey. The entry is confirmed with

the "OK", "Next" key or ▶. The TOPAX then goes to the next menu.

The key "back" or ◀leads to the previous menu.

4.11.7 Menu 0.4.3: pH output

With the arrow keys▲and ▼you can select between the options:

• Servomotor with potentiometer

• Servomotor without potentiometer

• Pulse frequency (Optocoupler)

• Pulse frequency (relay)

• Pulse length (relay)

• Continuous output (20 mA)

• 2-sides pulse frequency (relay) (Optocoupler)

• 2-sides pulse frequency (relay) (Relay)

• 2-sides pulse length (relay)

• ON/OFF (relay)

• No controller function

The selected option is highlighted in grey. The entry is confirmed with

the "OK", "Next" key or ▶. The TOPAX then goes to the next menu.

The key "back" or ◀leads to the previous menu.

4.11.8 Menu 0.4.5: Input temperature

With the arrow keys▲and ▼you can select between the options:

• ON

• OFF

The selected option is highlighted in grey. The entry is confirmed with

the "OK", "Next" key or ▶. The TOPAX then goes to the next menu.

The key "back" or ◀leads to the previous menu.

4.11.9 Menu 0.4.13: Input disturbance variable (optionally avail-

able)

With the arrow keys ▲and ▼you can select between the options:

• 0...20mA

• 4...20 mA

• OFF

The selected option is highlighted in grey.

To go back to the previous menu, press the key "back" or ◀.

4.11.10 Menu 0.5: Completing the configuration

The TOPAX moves immediately on to the configuration, at the latest after

menu 0.4.13, in the finalising menu (menu 0.5) and shows the chosen

configuration with all the previously chosen options in the total overview.

The configuration is saved with the “save” key and the finalising confir-

mation key “OK” and the TOPAX moves to the next menu 0.6.1.

The configuration starts from the beginning again with the key “back”.

The TOPAX then goes to menu 0.4.1.

4.11.11 Menu 0.6: Terminal connection clips

According to the chosen Options the TOPAX determines the relevant

terminal connections and shows this in menus 0.6.1 to 0.6.4 (each by

number of connections).

Disinfektion

input clamps analog

Next

check clamps and setup

pH value

Temperature

new configuration

51A - 52A

53 - 54

57 - 58

0.6.1

connect only with

main voltage off

Fig.13: Menu 0.6.1. - Example of a new configuration and the relevant terminal

connection plan. A changed configuration will be displayed red.

NOTICE!

Make a note of the given connections on the pre-

print in chapter “16 terminal connection diagram for

own configurations” on page 39..

In order to move between the individual menus 0.6.1 to 0.6.4, press

either the "next” or the “back” key, or the arrow keys ▲and ▼.

To finalise the total configuration confirm the connection plan with the

“OK” key. After confirming the configuration the TOPAX restarts and

switches to the standard display.

More information about the TOPAX menu structure are given in chapter

“12 Menu configuration and main settings” on page 29.

mg/l

Disinfection pH value

7.040.39

°C

temperature

26.3

Fig.14: Standard display with the measuring values.

BA-40400-02-V14 | 19

Operating instructions

NOTICE!

At start-up the controller outputs of your TOPAX will

be function-less for approx 60 seconds. This time

is required to stabilize the electrochemical sensors

connected. During the start phase the status display

indicates “Start in ….. s“ (seconds are shown). After

this period of time, the TOPAX is ready for operation.

NOTICE!

In order to prevent unauthorised manipulation, the

TOPAX has a password protection (see chapter

“12.1.23 Menus 5.9 and 5.10: Code und service

password” on page 35

4.12 Next steps

After a successful configuration the next steps are:

• Connect the sensors and the actuators - if not already connected

• Calibrate the sensors to the measuring output (see chapter “5

Measuring values inputs” on page 19)

• Set up the set point of the measuring inputs (see chapter “12.1.4

Menu 1.1: Target values” on page 30)

• Set up the controller (see chapter “12.1.8 Menu 2.1: adjust

controller” on page 32)

• Configuration of the regulating outputs (see chapter “7 Explanation

of measuring values outputs” on page 24)

NOTICE!

The configuration of the in- and output can be re-

called via the point “configuration” in the menu “ser-

vice” whilst in operation (see chapter “12.1.13 Menu

5: Service” on page 34). Here the changes to the

terminal plan are written in red figures.

5 Measuring values inputs

This section describes the chemical and physical correlations which are

necessary to understand the behaviour of the measurement inputs.

The measurement inputs are processed for:

• Disinfection

• pH value

• Redox potential

• Temperature

A key element is the calibration of the sensors.

ATTENTION!

When set up the unit for the first time, care should be

taken to perform individual calibration of each out-

put immediately after connecting the sensors in the

system. The TOPAX monitors all calibration processes

based on reasonable parameters (zero point and

transconductance). The readings are recorded. Non

calibrated and "poorly" calibrated measurements

inputs are shown in text form. "Poorly calibrated"

measurements are shown in the main display in red.

ATTENTION!

Note that time delays are possible due to the run-in

periods for the sensors.

The limits for "poorly calibrated" are:

Measurement Limits

pH value transconductance <40 mV/pH or

> 61 mV/pH

pH zero point < -40mV or

> 40mV

slope rate Redox < 0,85 mV / mV or

> 1,2 mV / mV

slope rate chlorine at

amperometric or potentiostatic measur-

ing cell

< 3 µA / mg/l or

> 100µA / mg/l

slope rate chlorine with encapsulated

electrode (0..2.00 mg/l)

< 3mA / mg/l or

> 13mA / mg/l

slope rate chlorine with encapsulated

electrode (0…5.00/10.00 mg/l)

< 1mA / mg/l or

> 5.2mg/l

The "poorly calibrated" display is only for reference and provides infor-

mation on the calibration quality and the state of the electrochemical

sensors.

Look for calibration faults and eliminate them. Replace the sensors as

soon as possible, if necessary. You can use the sensors unchanged until

replacement.

20 | BA-40400-02-V14

Two-Channel Controller TOPAX DE

5.1 Measurement input Disinfection (amperometric

measurement cells)

To measure the disinfection, amperometric measuring cells are used.

These measuring cells are used to measure the concentration of the free

hypochlorous acid ions if chlorine is used and/or the chlorine dioxide

ions. The ion concentration at the work electrode results in an electric

current flow which is analysed in the measurement amplifier.

Amperometric measuring cells can be classified according to the fol-

lowing criteria:

• open measuring cells,

• encapsulated electrodes.

If chlorine is used for disinfection, the dissociation of chlorine in the

water depending on the ph value is to be observed.

free chlorine

Hyperchlorous acid

Fig.15: The dissociation curve shows the dependence on the pH value

For photometric measurements the pH value of the sample is buffered

to approx. pH 6.5. As a result the measurement has a higher effective

chlorine content than is actually in the process water. For high pH-values

significant differences will therefore occur between the expected and

actual disinfection if assessed by photometric analysis. The main display

will show therefore two free chlorine values: The photometry value and

the effective chlorine content ("eff. chlorine") to kill germs at the cur-

rent pH value. For adjusting the display of effective chlorine see chapter

“12.1.28 menu 5.17: Display” on page 36.

5.1.1 Technical data

Amperometric measurement of disinfection can be done using am-

perometric 2-electrode measurement cells, amperometric 3-electrode

measurement cells with potentiostatic control or encapsulated elec-

trodes (measurement signal 4...20 mA).

Following measuring ranges are possible:

Sensor type Measuring range

Amperometric electrode

(Excess chlorine detector with 2 electrodes

type: CS120)

0…1.00 mg/l

0…2.00 mg/l

0…5.00 mg/l

0…10.00 mg/l

potentialstatic electrode

type: PE (for free chlorine or chlorine

dioxide)

0…1.00 mg/l or

0…2.00 mg/l

Encapsulated electrode

type: Cl 4.1 A 2 (for free chlorine)

type: CD 4 MA (for chlorine dioxide)

20 mA type;

Set measuring range based on

type of detector

Accuracy ± 1 % after calibration

5.1.2 Calibration

Calibration of amperometric, excess chlorine detector with 2

electrodes (CS120)

Before starting the calibration, the upper value of the measuring range

of the sensor must be defined in the TOPAX (see chapter “12.1.17 Menu

5.1: Inputs” on page 35).

Then the input must be calibrated using a two-point calibration (see

section “12.1.5 Menu 1.2: Calibration” on page 30):

The physical measurement (µA) measured on the measuring cell is

shown on the display during calibration.

Reference value 1: Zero point calibration

To perform zero-point calibration, operate the detector in chlorine-free

water or just stop the water flow through the instrument. The value of the

physical quantity shown on the display (approx 5-10 µA) can be saved

as soon as it stops changing. The device automatically changes to the

next menu section.

Reference value 2: DPD

The sensor is operated with sample water. If the physical value on the

display does not change anymore, the chlorine concentration in the sam-

ple water is determined by means of the DPD method. In order to avoid

signal variations and consequent reading errors, water must be taken

at the sensing element and the actual signal must be saved directly

in the TOPAX upon taking of the water sample. The chlorine content

in the sample water is determined by means of the DPD method. The

measurement must be set in the controller and saved by pressing OK.

After storage the transconductance value of the chlorine sensor is

shown. The typical resistivity value is approx. 25–35 µA (depending on

water type) per mg/l of free chlorine. The plausibility of the transcon-

ductance measurement is monitored throughout the process.

1-point calibration is sufficient (reference value 2) for validation of the

chlorine content after optimization.

Calibration of amperometric 3-electrode measurement cell

with potentiostatic control (PE)

Before starting the calibration, the upper value of the measuring range

of the sensor must be defined in the TOPAX (see chapter “12.1.17 Menu

5.1: Inputs” on page 35).

Then the input must be calibrated using a one-point calibration (see

section “12.1.5 Menu 1.2: Calibration” on page 30):

Calibration method: DPD

The sensor is operated with sample water. A nearly stable physical value

should be displayed. In order to avoid signal variations and consequent

reading errors, water must be taken at the sensing element and the

actual signal must be saved directly in the TOPAX upon taking of the

water sample. The chlorine content in the sample water is determined

by means of the DPD method. The measurement must be set in the

controller and saved by pressing OK.

After storage the transconductance value of the chlorine sensor is

shown. The typical resistivity value is approx. 35 µA (depending on water

type) per mg/l of free chlorine. The typical slope value is approx. 10 µA

per mg/l of free chlorine dioxide.

The plausibility of the transconductance measurement is monitored

throughout the process.

Table of contents

Other Jesco Controllers manuals

Popular Controllers manuals by other brands

Emerson

Emerson AW Series Installation and operation manual

Wenglor

Wenglor LV250 operating instructions

Sauter Components

Sauter Components ASM 124 F120 quick start guide

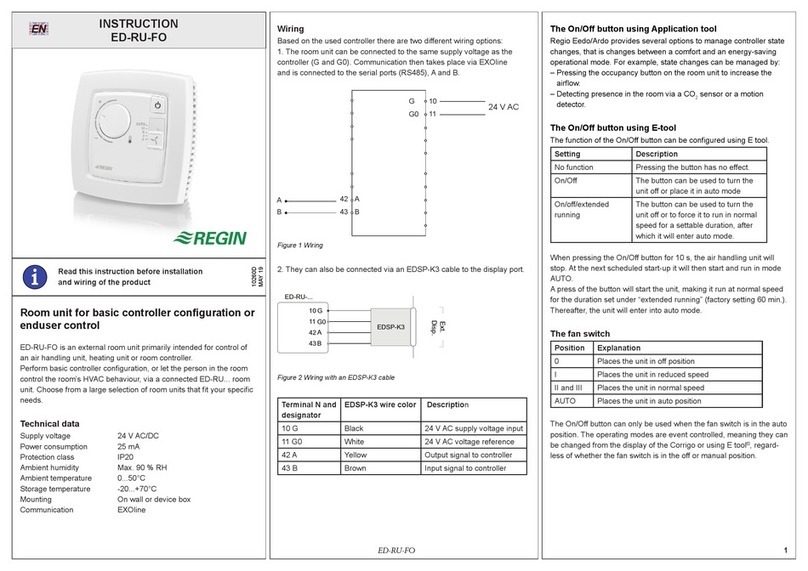

Regin

Regin ED-RU-FO instruction manual

Siemens

Siemens SIMATIC EMS400S PSB-S operating instructions

Geotech

Geotech Geocontrol PRO Installation and operation manual