4

Assembly & Adjustment

(refer to exploded views)

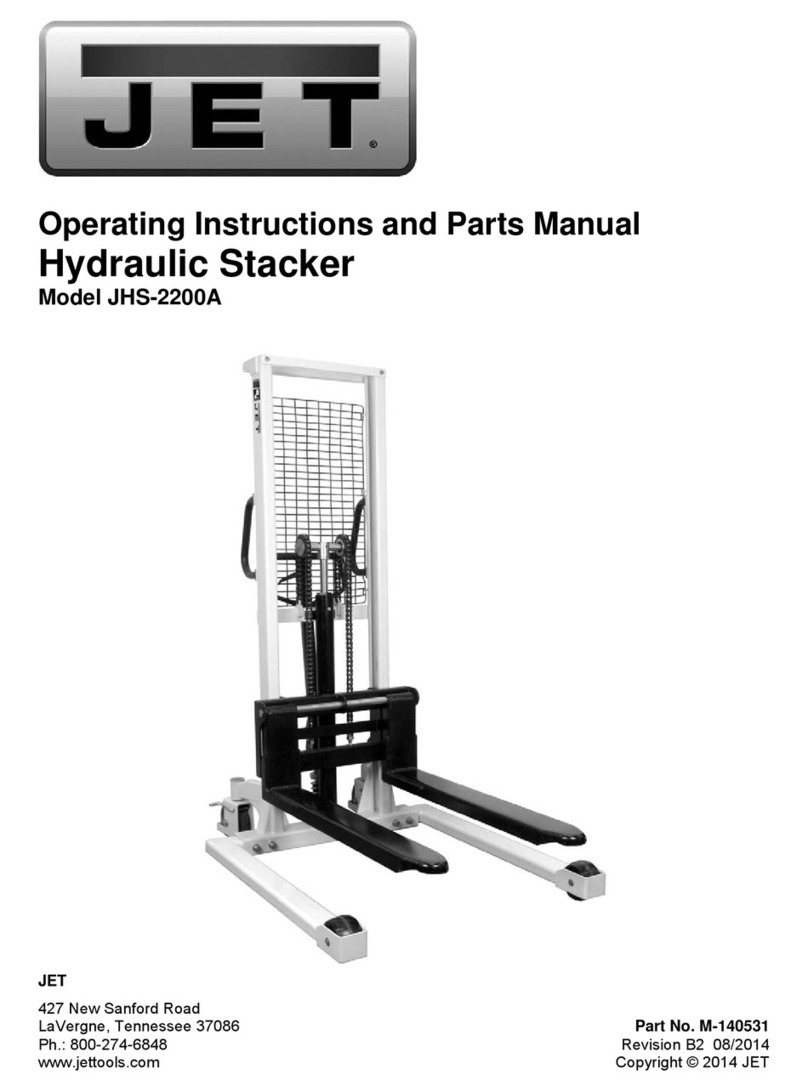

1. Remove packing material carefully and

inspect for any damage during shipment.

2. Insert handle (102) into the socket of

cylinder (160); lock it with pin (108) and two

screws (109). Swing the handle up and

down to see if it moves freely. Attach

tension spring (105).

3. Open electrical control case by removing

thumb screws (256) and cover (255). Insert

up/down switch wire and plug (184) hanging

down from handle (102) into socket (221) in

the case. Insert two 5 Amp fuses (277) into

two sockets F1/F2.

4. Check the electrical device and elements in

the case to make sure none are loose or

damaged. Tighten any elements if loose.

5. Check high pressure oil pipe (282) in the

hydraulic system to confirm it is not loose.

Tighten if loose. Open cover (217) to check

hydraulic level.

6. Push “Up” button (197) on top of handle

(102) intermittently to lift the fork. Push and

hold the “Up” button to lift the forks to their

highest position. Then push and hold the

“Down” button (197) to lower the forks to

their lowest position. Repeat this procedure

3 to 4 times with full up and down travel to

release any possible air in the hydraulic

system and to confirm all components are

functioning correctly.

7. Close cover (255).

Safety Precautions

1. Read and understand owner's manual

before operation.

2. Do not exceed rated capacity.

3. Before using pallet truck, lift and lower the

forks several times with no load to release

any air that may be trapped in the hydraulic

system.

4. Never allow anyone to ride on the pallet

truck.

5. Operate on smooth, level finished floors

only. Automatic brake system will not

engage properly if forks are raised on

uneven floor. Do not use on slope.

6. Always keep hands and feet clear from all

moving parts including forks, legs, piston

rod (406) and mid-cylinder (413).

7. Always secure load equally on the forks

nearest the bulkhead before lifting or

lowering. Do not lift load with fork tip only.

8. Automatic overload safety valve will open if

pallet truck is overloaded. If overloaded, do

not push the "Up" button as this will reduce

the life of the pump station.

9. When transporting loads, always keep

people clear from pallet truck and transport

in the lowered position only.

WARNING

Failure to comply with all of these safety

precautions may result in loss of load,

damage to pallet truck, personal injury

and/or property damage.

Operation

The pallet truck is designed for use with open

style pallets or skids only. Closed style pallets

must be placed on top of forks prior to use.

The handle is designed to pull and steer the

pallet truck only. Do not use the handle as a

leverage tool.

WARNING

Do not attempt to move pallet truck with

forks in raised position. Lower forks

completely before moving pallet truck.

To raise forks, press the “Up” button in the

center of the handle, hold until desired height is

achieved, then release. The automatic brake

system featuring two axles (7) will engage the

floor to prevent movement.

To lower forks, press the “Down” button, hold

until desired height is achieved, then release.

The forks can be stopped at any position and

will hold firmly in place.

The pump assembly features an overload safety

valve. When the pallet truck lifts beyond its

maximum capacity, only the mid-cylinder (413)

will extend out fully; the piston rod (406) cannot

extend.

If pallet truck is overloaded, the mid-cylinder

(413) only will rise. The pison rod (406) will not.

Avoid pushing the "Up" button when overloaded

to prevent any damage to the pump station.