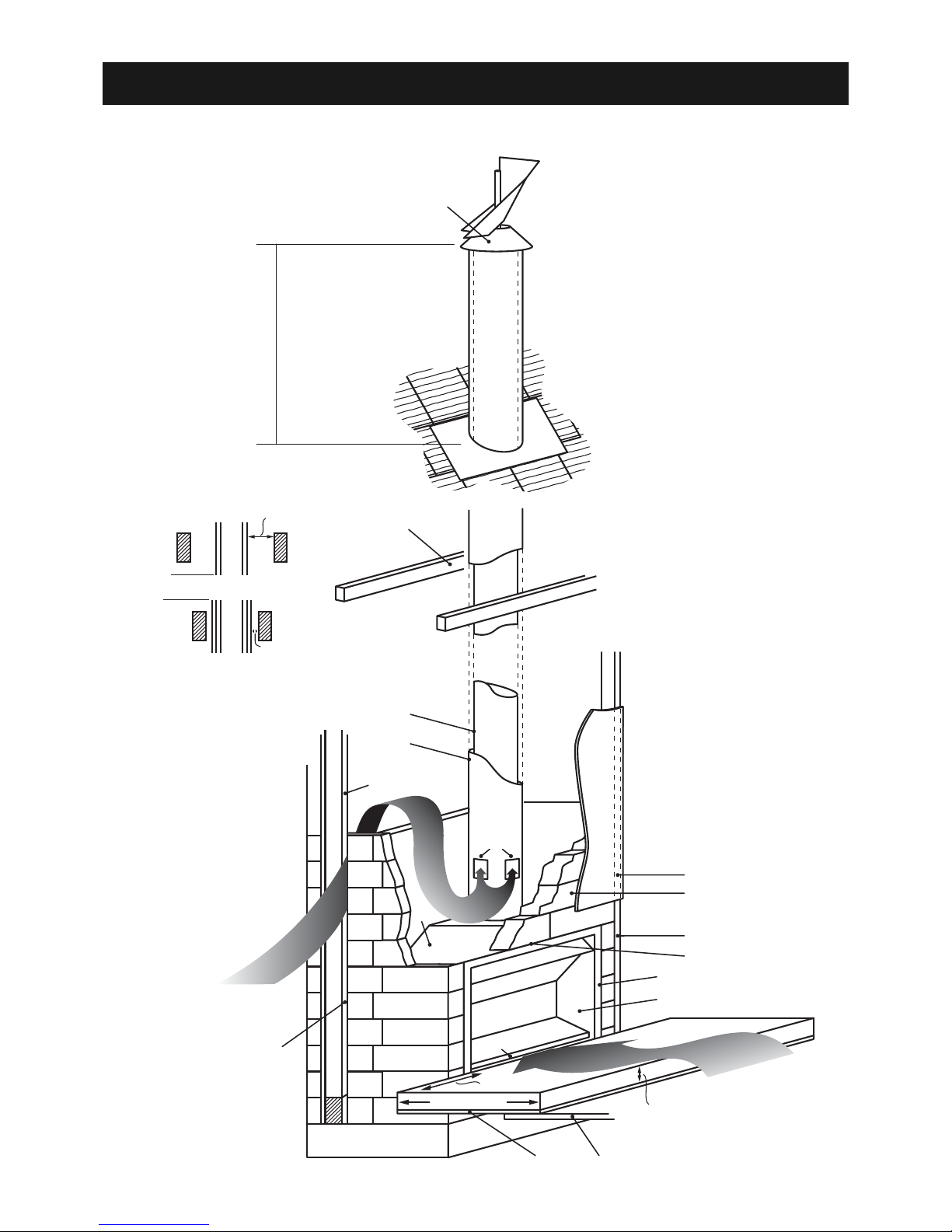

Installation With Full Brick Chimney

Step by step check list

Warning! Please read these instructions carefully. Failure to

adequately follow the instructions can result in serious injury

or death.

1. Position firebox on a non-combustible hearth-see diagram

1 page 7 (summary of minimum installation specs.)

2. Bolt gather to firebox.

3. Insulate entire firebox and gather where painted red with

the insulation provided.

4. If using a Jetmaster lintel, bolt lintel to firebox. If using an

angle bar as a lintel you can use the side Hebel or brickwork

to support the lintel - insulate between lintel and firebox.You

can lay your Hebel or brickwork directly onto the top of the

firebox between the gather and front flange of the firebox.

However it is important to insulate between the brickwork

and firebox.

5. Ensure air intake area at bottom of unit is not obstructed

6. Brick around firebox

7. Do not recess the firebox by more than 110mm.A greater

dimension could result in compromise in convected heat.

8. Rivet inner active flue with uncrimped end facing down to

collar of gather at three places.

Rivet active flues together at crimped joins.

Encase the flue with brickwork and it is suggested that a piece

of 9mm fibre cement sheeting with a circular cut out to

accommodate the flue be positioned on the chimney opening,

one course of brickwork from the top of the chimney. Slope

mortar outward from the flue which should protrude through

the cement sheet by 50mm (see diagram page 7 alternative

brick chimney termination.

9. Fit a recommended Jetmaster flue cowl to the top of

chimney.

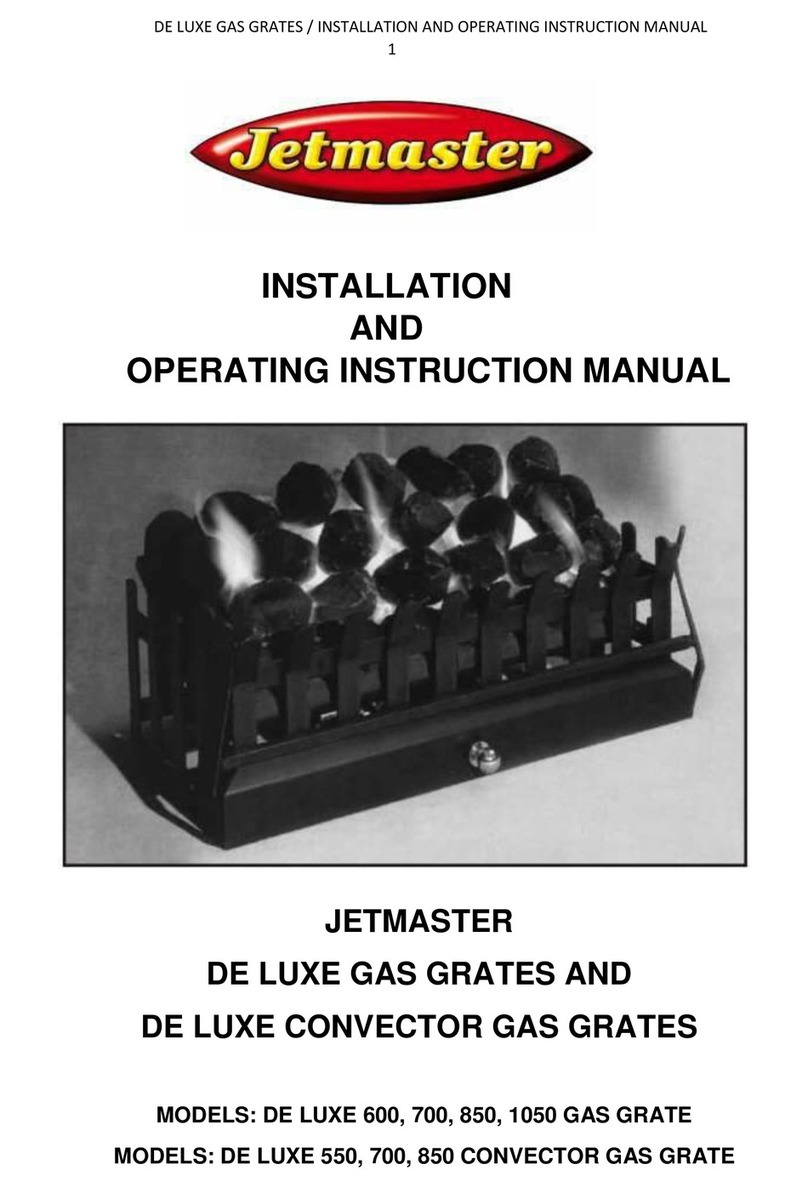

10. Gas burning - A ½ inch BSP inlet on right hand side is

required. Drill at 100mm from base and rear of firebox from

outside of firebox. Avoid penetrating the firebox from the

rear.

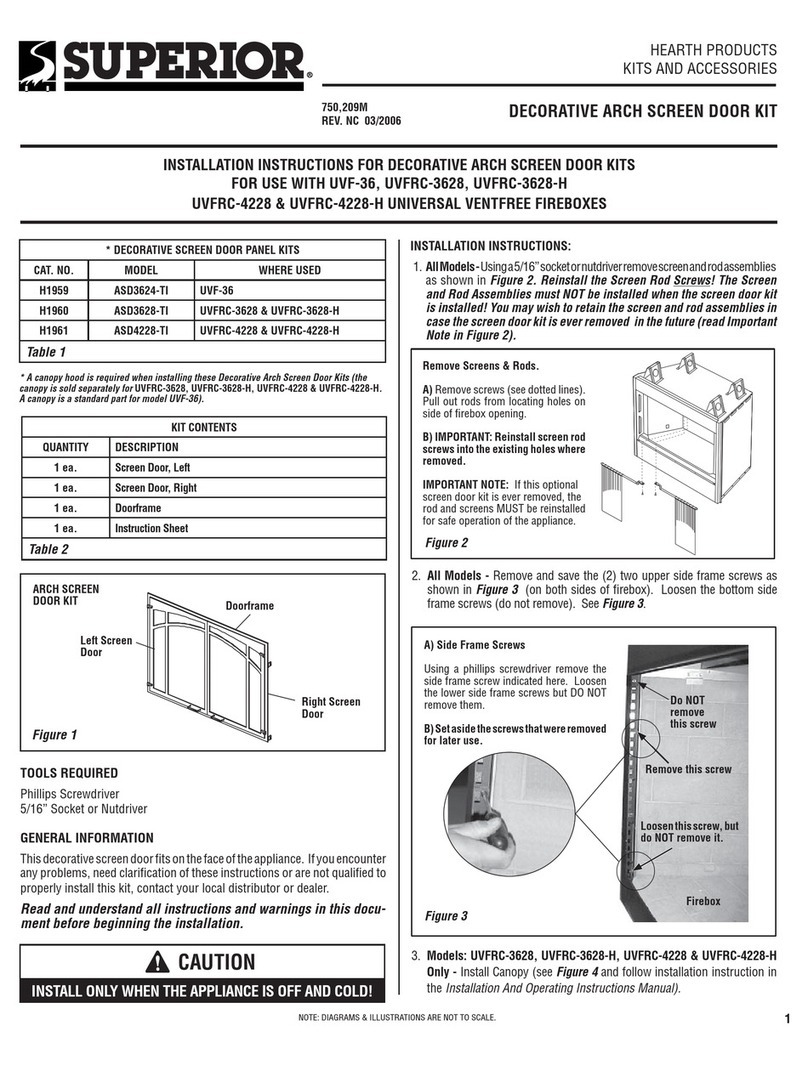

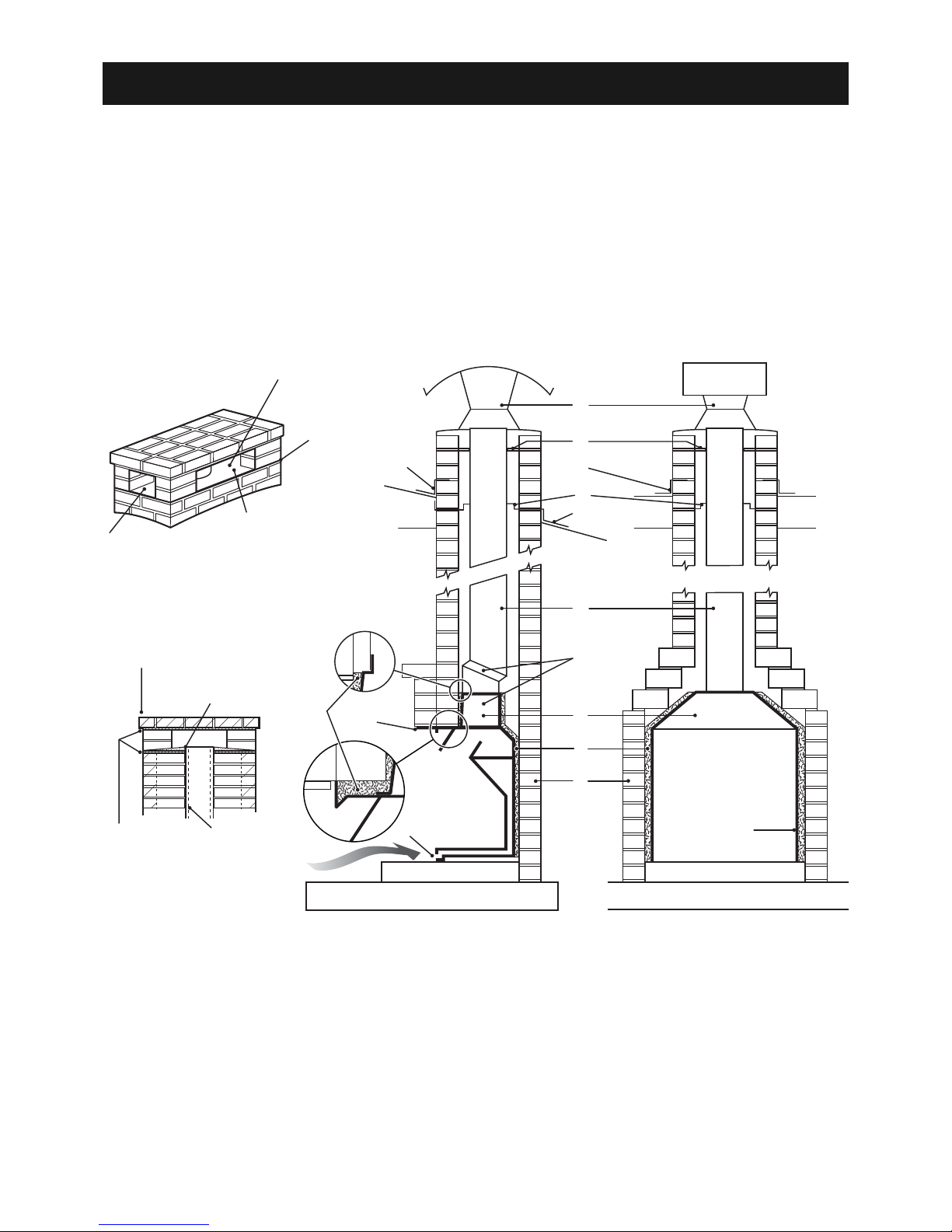

Installation with full brick

chimney

1. Re-inforced concrete foundation.

Suspended floors will require supports and footings.

2. Hearth.

3.Air inlet. DO NOT BLOCK.

4. Firebox.

5. Gather.

6. Optional lintel, as firebox supports brick wall. (If other than

the Jetmaster lintel used, a 100 x 10 angle bar is needed and

allow at least 2 mm for expansion.

7. Insulation.

8. 115 minimum brickwork.

9. Gap between stainless steel flue and brickwork may

(optional) be filled with mortar (8 sand, 3 lime, 1 cement).

10.Approved Flashing.

11. Drip tray.

12. Jetmaster stationary cowl, rotating cowl, (also see diagram

alternative brick termination-this page) A.G.A gas approved

cowl when using gas.

13. Optional 45 degree bends or offset gather available.

14. Fibre cement sheet under last course of bricks with hole

cut to restrain flue. Provide outer sleeve to allow for

expansion and contraction of active flue and base cowl when

filling with mortar.

15. For burning gas: 1/2-inch B.S.P. inlet on right hand side of

firebox is recommended. Drill at 100 mm from base and rear

of the firebox measuring on outside of firebox.

Important points

• Do not block air inlet. Cover all surfaces of fireplace,

including, gather, with insulation provided.

• Build the brickwork at the back and sides of the fireplace

against insulation. Seal any gaps between gather and firebox

with the fire cement or insulation provided.

PAGE 9