1. General information

The MJet V0 and V0 HD is unique devices for installing fiber optic directly into a pipe. The MJet V0 HD is

consist of an air block/pipe clamp and a drive wheel that, when combined installs a fiber into an airtight

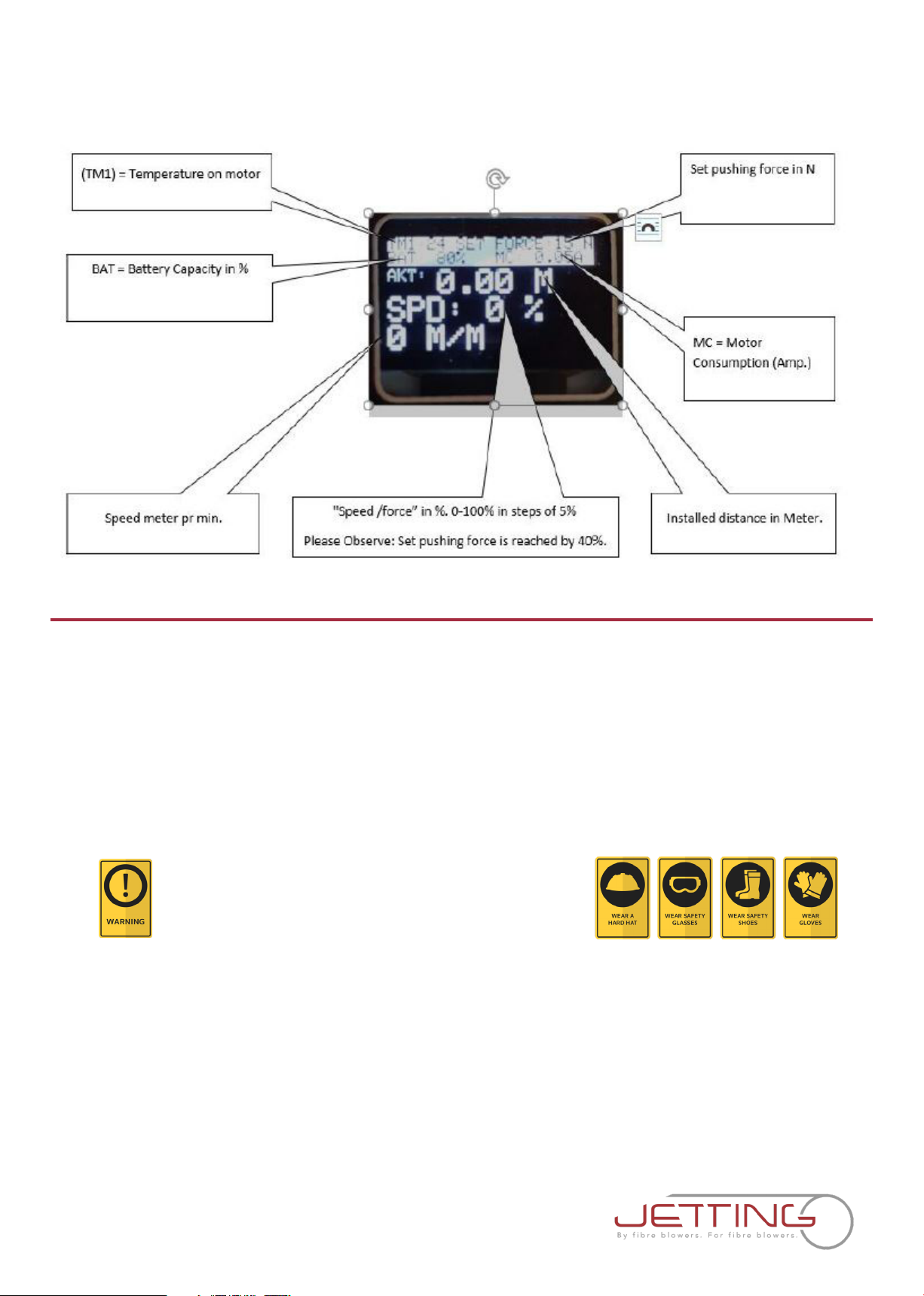

pipe. The V0 HD has 200 N in pushingforce and speed is 0-110 m/min.

The MJet V0 HD’s built in adjustable clamp force, greatly optimize the pulling stress on the fiber.

The electronic fiber protection system stops the motor within 250 ms. if the wheels are not running

synchronized (like if the fiber hits an obstruction).

The MJet V0 HD comes standard with a digital LCD Meter Display, 2 pcs 18 V, 4 Ah lithium batteries and

charger in a hard side case.

These operating instructions contain a full description of the MJet V0 HD, which have been designed

for the purpose of feeding fiber through a pipe. The pipe must have previously been installed

underground or overhead to receive the fiber optic and must be of sucient length on exit to be

received by the machine. The pipe must be of material with sucient compression strength for it to be

adequately sealed in the pipe clamps of the machine. The pipe must be airtight up to a pressure of

16bar. Pipe sizes range from 3 mm-16 mm, while fiber optic fiber(s) range from 0,5 mm-6,5 mm.

The MJet V0 HD consists of an air block/pipe clamp that is made in two halves that clamp together

around the pipe. The pipe clamp holds a seal that the fiber optic fiber is fed through before entering

the pipe. The pipe clamp and fiber seals can be interchanged to accommodate dierent pipe and

fiber sizes. The pipe is mechanically clamped between the duct clamps at the exit of the pipe clamp,

preventing movement in any direction. Seals conform around the pipe when clamped.

The fiber optic is fed through the pipe by a combined pulling/pushing force. The pulling force is achieved

when pressurized air is fed into the air block and forced into the duct, generating drag on the fiber from

the airflow passing over it. The pushing force is created by engaging the drive wheel system. As the

drive wheel feeds fiber into the pipe, drag force is created by the airflow. The fiber optic floats in the

pipe, minimizing any resistance to being pushed in by the drive wheel.

The use of the MJet V0 HD for operations other than those described in this manual are considered

dangerous and are discouraged. Use of this machine for work other then what is intended, relieves the

manufacturer from any responsibility, civil or penal. The manufacturer's responsibility ceases, and the

warranty is voided when one of the following occurs:

A. When MJet V0 HD is used for purposes other than what is detailed in this manual.

B. Tampering and/or modifications carried out without written approval of the manufacturer.

C. Not using original manufactured replacement parts.

D. Poor maintenance.

E. Not using supplied safety devices or equipment.

F. Connection of this unit to machines and/or parts not produced or authorized in writing by the

manufacturer.

G. The MJet V0 HD should not be used to install any fiber other than optic fiber specified within the

range outlined in this instruction manual.

Jetting AB is not responsible for injuries incurred as a result of improper use of the MJet V0 HD.