Jewell Instruments DX Series User Manual V.81814

2

Contents

1. General Information...................................................................................................................6

A. About this Manual ..................................................................................................................6

i. Related Documentation / Applications.........................................................................6

ii. Documentation Conventions...........................................................................................6

B. Warranty ...................................................................................................................................7

2. Product Overview.......................................................................................................................8

A. Introduction to the DX Series ................................................................................................8

i. Features and Options.........................................................................................................8

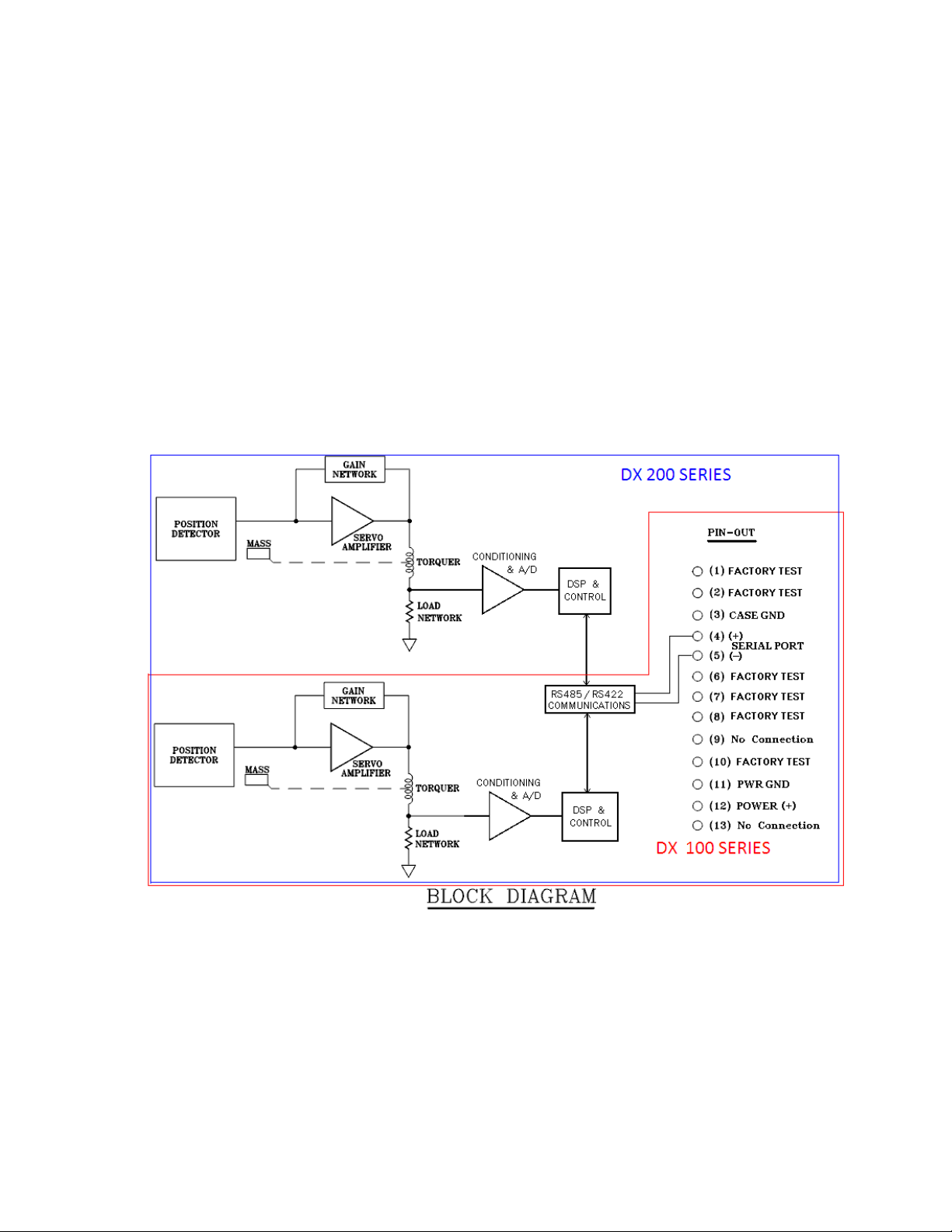

ii. Internal Diagram .................................................................................................................9

iii. Typical Applications .........................................................................................................10

B. DX Series Installation.............................................................................................................10

i. Mechanical........................................................................................................................10

ii. Electrical .............................................................................................................................12

3. Basic Operating Tenants.........................................................................................................13

A. Getting Started......................................................................................................................13

i. Default Settings..................................................................................................................13

ii. Terminal Programs.............................................................................................................14

iii. Connecting to the Serial Interface ...............................................................................14

B. Operational Modes..............................................................................................................14

i. RS422....................................................................................................................................15

ii. RS485....................................................................................................................................15

iii. Temporary RS485...............................................................................................................15

C. Serial Communications........................................................................................................16

i. Packet Structure................................................................................................................16

ii. Using DX Series Commands ............................................................................................19

4. Building Command Structures...................................................................................................20

A. Full List of Serial Commands................................................................................................21

i. Configuring Measurement Outputs ..............................................................................21

ii. Configuring Transmission Parameters ...........................................................................25

iii. Maintenance and Infrastructure Inputs .......................................................................29