B-06-1006, Rev. E Tuff Tilt Digital 1

TUFF TILT DIGITAL TILTMETER

TABLE OF CONTENTS

1 - INTRODUCTION......................................................................................................................................2

2 - INSTALLING THE TILTMETER, MAKING CONNECTIONS, TILT DIRECTIONS.......................... 6

3 - POWER REQUIREMENTS AND GROUNDING .............................................................................. 6

4 - COMMUNICATING WITH THE TUFF TILT ..................................................................................... 9

4.1 Basic Requirements and Settings ........................................................................................... 9

4.2 Firmware Command Format..................................................................................................... 9

4.3 Firmware Command Summary............................................................................................... 10

4.4 Sample Data Using the XY Command................................................................................... 12

5 - MAINTENANCE AND TROUBLESHOOTING ............................................................................... 13

APPENDIX A - FIRMWARE COMMANDS.......................................................................................... 14

APPENDIX B - ZAGI GRAPHICAL INTERFACE SOFTWARE (Installation & Operation) .............. 28

1 Introduction................................................................................................................................. 29

2 System Requirements................................................................................................................ 29

3 Installing ZAGI ............................................................................................................................ 29

4 Configuring Communications................................................................................................... 30

5 Data Access ................................................................................................................................ 31

6 Command Line Menu Options .................................................................................................. 32

7 Screen Options........................................................................................................................... 33

8 Equivalent Firmware Commands.............................................................................................. 34

9 Event Markers; Plotting Saved Files ........................................................................................ 35

10 Data Logging to Tiltmeter Memory........................................................................................... 35

11 Data File Format......................................................................................................................... 36

12 Printing........................................................................................................................................ 37

APPENDIX C - WARRANTY AND LIMITATION OF LIABILITY......................................................... 39

APPENDIX D - REVISION RECORD................................................................................................... 41

LIST OF FIGURES:

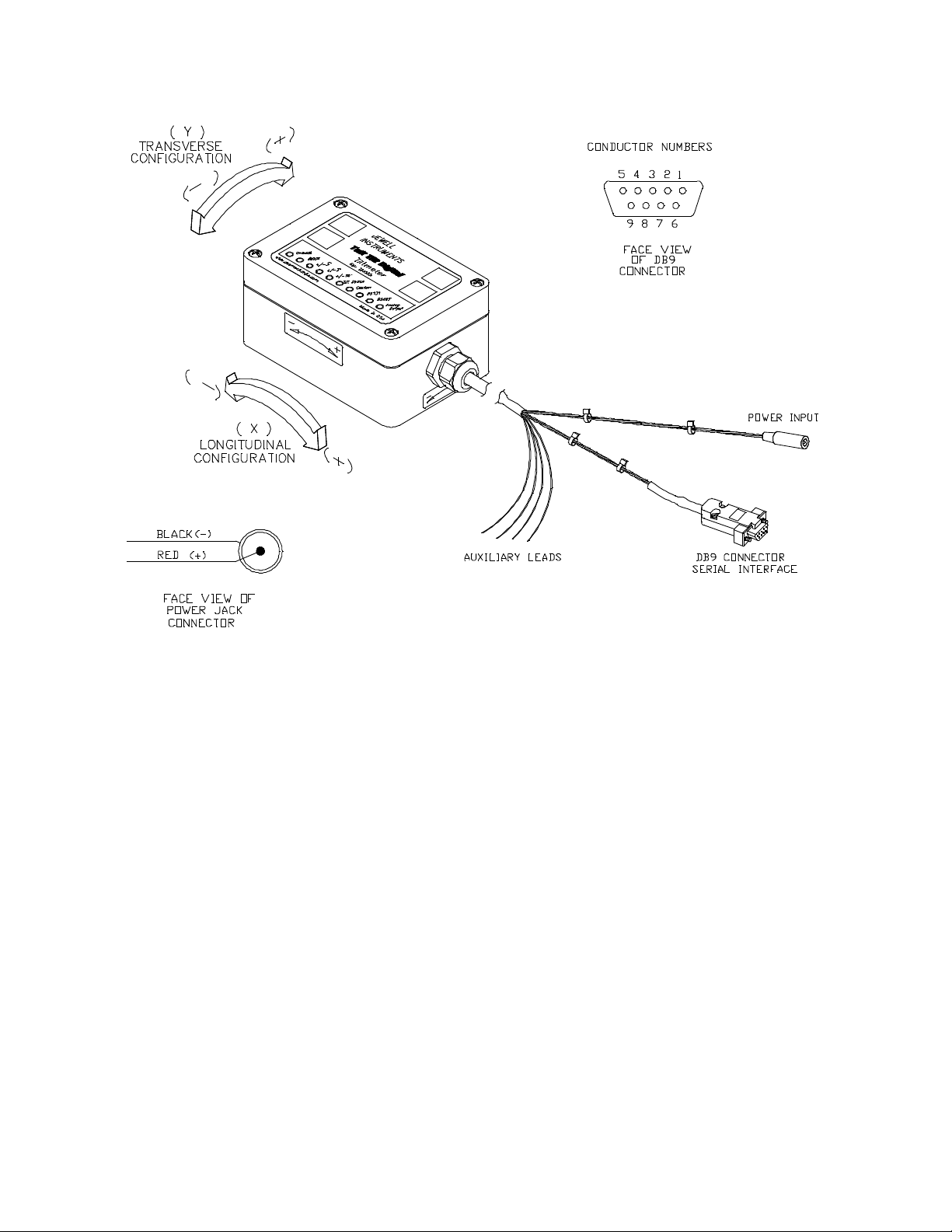

Figure 1: The Tuff Tilt Digital ............................................................................................................... 2

Figure 2: Instrument Mounting Hole Locations.................................................................................... 3

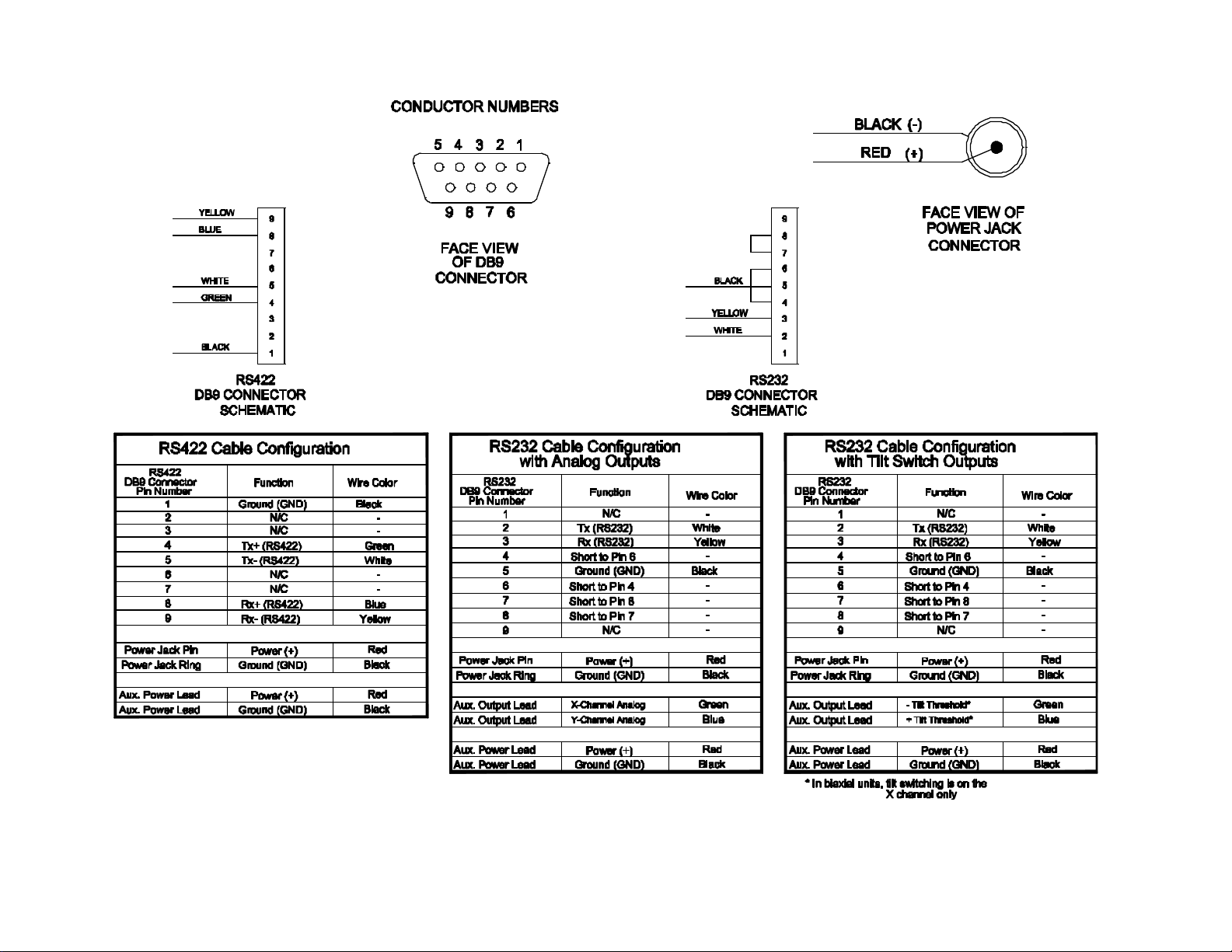

Figure 3: Cable Termination Detail...................................................................................................... 4

Figure 4: Wiring Connections .............................................................................................................. 5

Figure 5: Installation Methods.............................................................................................................. 7

Figure 6: Box Mounting Details............................................................................................................ 8