PAGE 2 of 33

Chapter 2

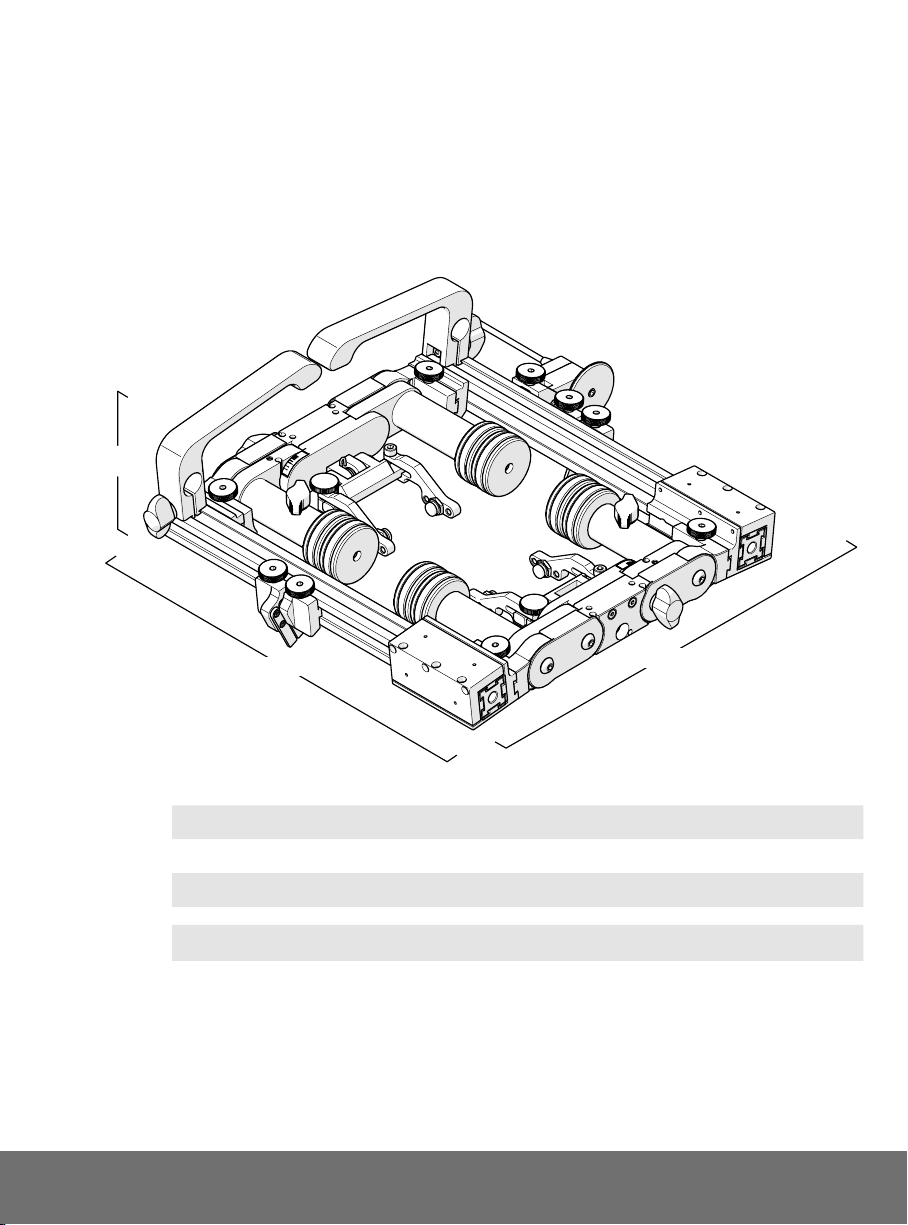

PRODUCT SPECIFICATIONS

2.1. Intended Use

The scanner’s primary purpose is to move an inspection tool over a cylindrical surface

for inspection of flanges.

The intended surface is to:

►be free of excess rust, scale, ferrous debris, ice, frost

►have a minimum OD of 102 mm (3 in) for two probe arrangement

2.1.1. Operating Limits

Minimum Maximum

Flange Range, Outer Diameter: 7.6 cm (3 in) Flat

Radial Scanner Clearance (with handles): 9.7 cm (3.8 in)

Radial Scanner Clearance (without handles): 4.1 cm (1.6 in)

2.1.2. Operating environment

►the scanner is intended for industrial use only

►operating ambient temperature between -20° C (-4° F) and 50° C (122° F).

2.1.3. User

►the scanner is intended to be used by persons who have read and

understand the user manual.

►the scanner is intended to be used by persons without limitations in the

physical abilities of the upper and lower limbs, sight, hearing, or anyone with

a pacemaker