PAGE iii of iv CE0120 Rev 05

4.12.4. Slip Joint Probe Holder Left/Right Conversion 18

4.13. Cable Management System 20

4.13.1. Cable Management Dovetail Mount 20

4.13.2. Cable Management Setup 21

4.13.3. Clamp Setup 22

4.14. Reduced Width Scanning Kit 22

4.15. Vertical Probe Holder 23

4.15.1. Probe Holder Setup 23

4.15.2. Probe Holder Vertical Adjustment 24

4.15.3. Probe Holder Transverse Adjustment 25

4.15.4. Probe Holder Longitudinal Adjustment 26

4.15.5. Probe Holder Left/Right Conversion 27

4.16. High Temperature Weld Frame Scanner 29

4.17. Magnetic Wheel Kit 30

4.18. Pre-amp Bracket 31

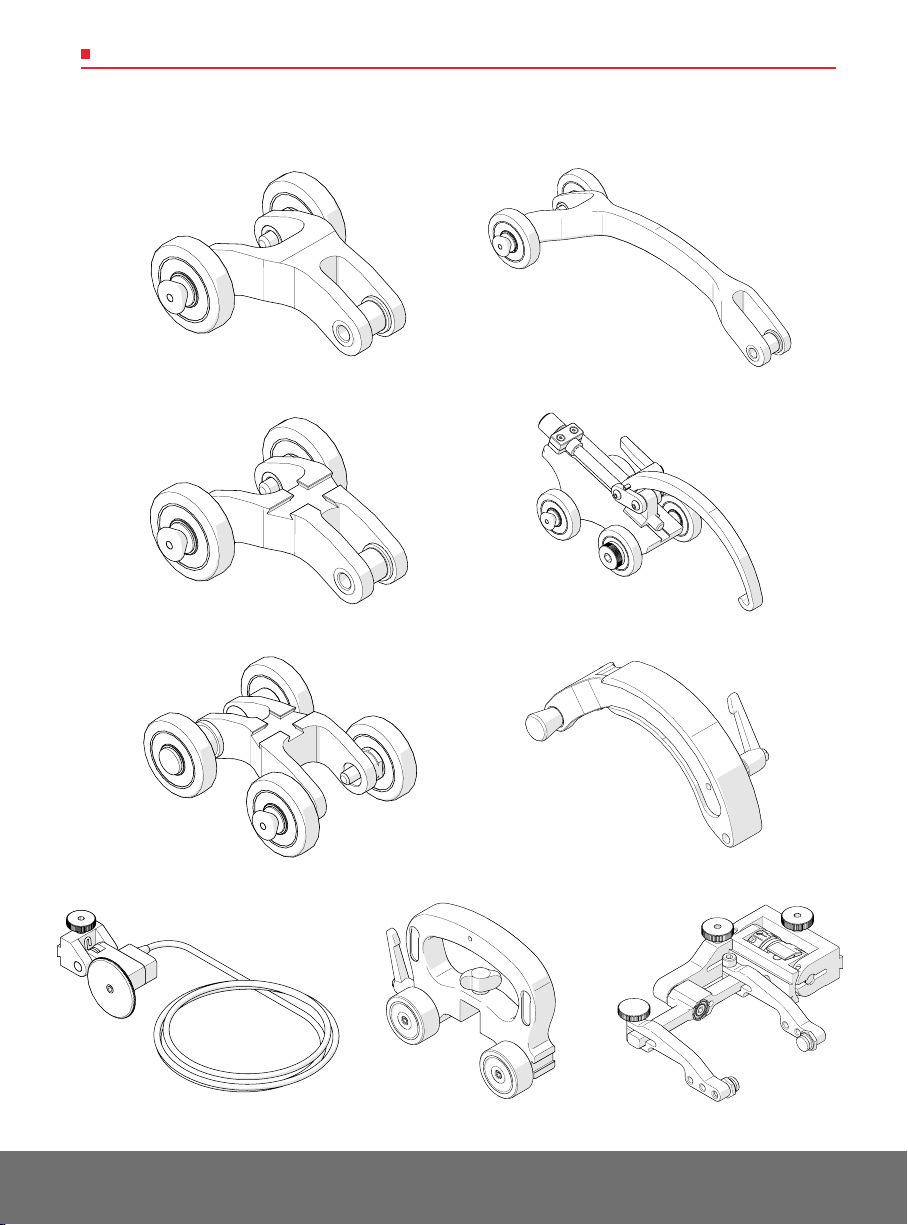

Chapter5 Configurations 32

5.1. Two Probe Scanning 32

5.2. Four Probe Scanning 32

5.3. Four Probe Cantilever Scanning 33

Chapter6 Operation 34

6.1. Setup of ROTIX on a Scanning Surface 34

Chapter7 Maintenance 38

Chapter8 Troubleshooting 39

8.1. Technical Support 39

Chapter9 Spare Parts 40

9.1. Standard Kit Components 40

9.2. High Temperature Kit Components 41

9.2.1. Encoder Connector Type 42

9.3. Accessories 42

9.3.1. Cable Management, Dovetail Mount 42

9.3.1.1 Cable Management Sleeving 42

9.3.2. High Temperature Cable Management, Dovetail Mount 43

9.3.3. Pre-Amp Bracket 43