Content

1 Safety Instruction..................................................................................................................... 1

1.1 Safety identification........................................................................................................1

1.2 Safety instruction............................................................................................................ 2

2 Products Introduction.............................................................................................................5

2.1Household PV off-grid Power Generation System Introduction.........................5

2.2 Product Introduction.......................................................................................................6

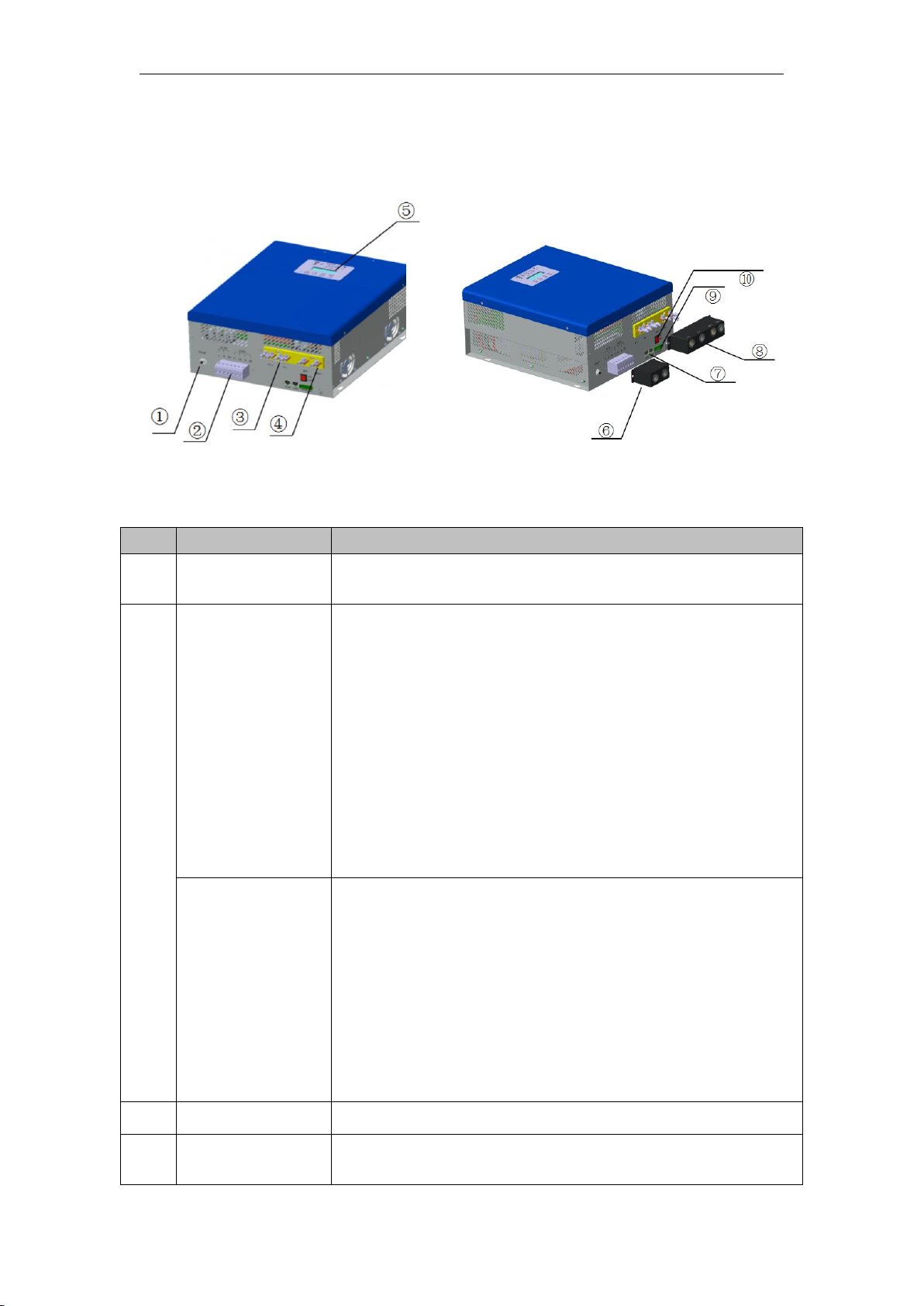

2.2.1 Appearance Introduction.................................................................................... 6

2.2.2 Production Dimensions....................................................................................... 7

3 Inverter & Controller Unpacking Installation................................................................ 9

3.1 Unpacking Inspection.................................................................................................... 9

3.2 Prepare Installation Tools.......................................................................................... 10

3.3 Hanging-mounted Installation...................................................................................10

3.4 Electrical connection................................................................................................... 12

3.4.1 PV Input Connection......................................................................................... 13

3.4.2 AC Input Connection......................................................................................... 14

3.4.3 Battery Connection............................................................................................ 18

3.4.4 AC Output Connection..................................................................................... 20

3.4.5 Communication Ports Connection................................................................23

4 Commissioning........................................................................................................................25

4.1 Electrical Connection Inspection before Commissioning.................................25

4.2 Charging Commissioning........................................................................................... 25

4.2.1 PV Charging Commissioning.......................................................................... 25

4.3 Liquid crystal operation instructions.......................................................................29

4.3.1 All-in-one LCD display...................................................................................... 29

4.3.2 LIQUID crystal display interface.................................................................... 30

4.3.3 CONTENTS of LCD display............................................................................ 31

4.3.4 Liquid crystal function information................................................................ 33

5 Common troubleshooting and maintenance...............................................................42

5.1 Troubleshooting............................................................................................................ 42

5.2 maintenance...................................................................................................................54

6 Appendix A technical parameters....................................................................................55

7 appendix B................................................................................................................................ 59

8 Appendix C................................................................................................................................. 60